Friulmac Automatic Double End Tenoner "Idramat S/TC 4 WS-2500"  Preview

Preview

Friulmac Double End Tenoner and Busllato CNC Auction - Owensboro, KY

Owensboro, KY

Starts In remaining

Friulmac Double End Tenoner and Busellato CNC Auction - Owensboro, KY ( Preview #76399687 )

A Family owned window supplier in the greater Louisville, KY area is auctioning a Friulmac Automatic Double End Tenoner "Idramat S/TC 4" and Busellato " Jet Concept XXL CNC Router no longer required for continuing operations. Please call me directly with any questions.

-

Pick Up Location

1515 E. 18th St. Owensboro, KY 42303

-

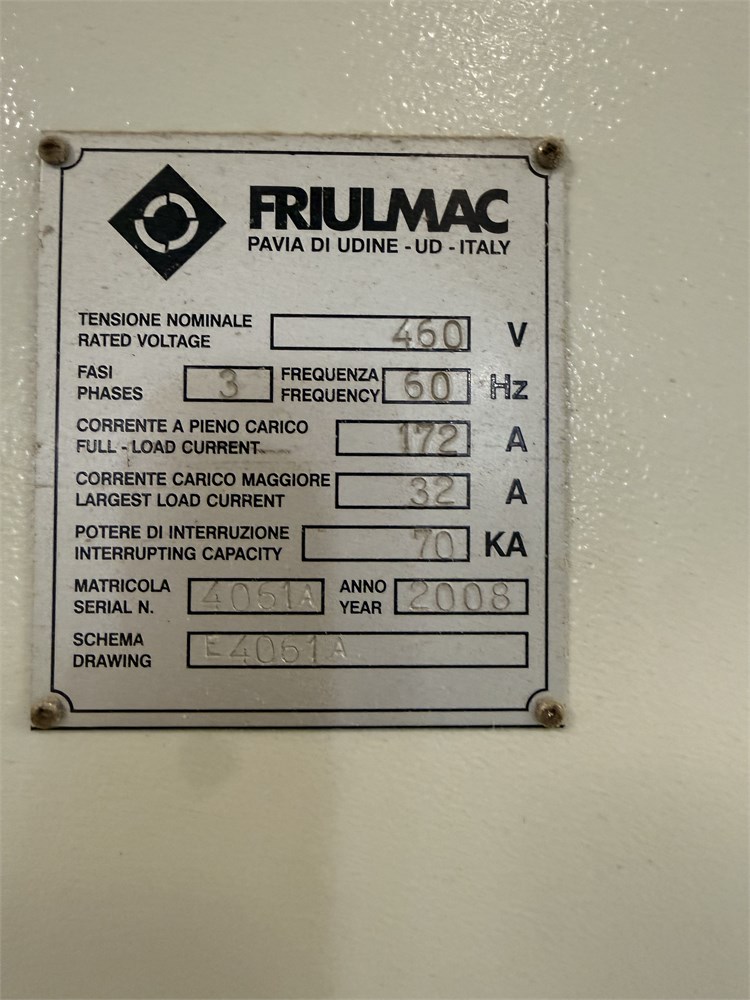

Make

Friulmac

-

Model

Idramat S/TC 4 WS-2500

-

Serial Number

4061A

-

Year

2008

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Buyer Inspection Period

November 14th - November 25th, 2025 By appointment only

-

Load Out Period

November 24th- December 12th, 2025 By appointment only

-

Estimated Dimensions

25' L x 25' W x 8' H

-

Estimated Weight

20,000 Pounds

-

Seller Comment

A Rigger is required for load out. Please see homepage for details

-

Load Fee

-

Lot Notes

-

page views

7

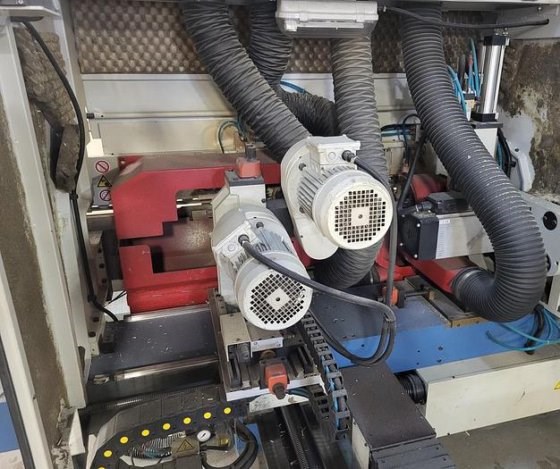

Friulmac Automatic Double End Tenoner "Idramat S/TC 4 WS-2500"

1st station:

TRIMMING UNIT ‘B-

TRIMMING UNIT ‘B-

Composed of one horizontal cutting spindle assembled on supporting column;

The supporting column is arranged for the assembling of a second scoring horizontal spindle;

Spindle diameter :

Rotation speed : 7600 rpm

Motor capacity : 3 Kw

Blade diameter : min.125 max.180 mm (supplied with diameter )

Spindle adjustment in height :

Spindle adjustment in depth :

The measures are visualised on mechanical digital indicators; transmission by means of Poly V belt; the unit is assembled on a transversally movable table on precision linear guides; the table sliding movement is opposite with respect to the pieces feeding direction and it is driven by pneumatic cylinder; the working is done on "clamped piece".

Dust extraction:

Nr. 1 hole outside diameter :

Required air speed : 30 m/sec

Air consumption : 1220 m³/h

SCORING UNIT ‘B-

SCORING UNIT ‘B-

Composed of one horizontal cutting spindle provided with motor, assembled on the supporting column of the principal unit;

Spindle diameter :

Rotation speed : 7600 rpm

Motor capacity : 3 Kw

Blades diameter : min.125 - max.

Spindle adjustment in height :

Spindle adjustment in depth :

Transmission by means of Poly V belt; The measures are visualised on mechanical digital indicators.

Dust extraction:

Nr. 1 hole outside diameter : .

Required air speed : 30 m/sec

Air consumption : 1220 m³/h

Special equipments on the units:

- No. 2 + 2 “B-8/B- horizontal spindle modification for hogging tools installation.

2nd station:

HAUNCHING UNIT ‘I-

HAUNCHING UNIT ‘I- Composed of a movable body that slides vertically on precision linear guides, supporting an horizontal spindle provided with high speed bearings, it is driven by means of toothed belt, by electric motor.

The vertical movement of the unit driven by pneumatic cylinder;

Stroke :

Spindle diameter :

Spindle usable length :

Rotation speed : 5600 rpm

Motor capacity : 4 Kw

Min/Max tool diameter (excluded from the supply) : to be defined (max weight )

Max. profiling depth :

Unit adjustment in profiling depth :

Unit adjustment in the work piece width sense :

The working is done on "clamped piece" positioned onto anti break out back up block.

Dust extraction:

Nr. 1 hole outside diameter : 125x80 mm

Required air speed : 30 mt/sec

Air consumption : 1080 m³/h

Compressed air consumption : 150 lt/min

Special equipments on the unit:

- Fast tool change system for profiling unit (max. work-piece width ).

-

3rd station:

CNC ROUTING UNIT “J-

Compose by a working unit adjustable in height on supporting column by means of screw TPN; the measures are visualised on mechanical digital read-out; The group column/unit is assembled on a movable base that slides in transversal and longitudinal sense with respect to the piece; both movements are driven by brushless motors and are interpolated by CNC; these movements are realised on precision linear guides by means of ball screw; The working unit is composed by an electro-spindle driven by inverter;

Compose by a working unit adjustable in height on supporting column by means of screw TPN; the measures are visualised on mechanical digital read-out; The group column/unit is assembled on a movable base that slides in transversal and longitudinal sense with respect to the piece; both movements are driven by brushless motors and are interpolated by CNC; these movements are realised on precision linear guides by means of ball screw; The working unit is composed by an electro-spindle driven by inverter; The working movement is programmed in function of the tool rotation direction and it is done on “clamped piece”.

Spindle rotation speed : from 7000 to 18000 rpm

Motor capacity : 4,5/8 Kw with inverter

Tool holding fixture : cone ISO 30 with pincers

max. diam. , ER40

Spindle height adjustment :

Interpolated working stroke in the work piece width :

Interpolated working stroke in the work piece depth :

Tool cutting circle (excluded from the supply):

Speed (Rpm)

Diameter (mm)

Weight (Kg)

5000-9000

150

4

9000-12000

130

4

12000-14000

100

2.5

14000-18000

80

2.5

4th station:

FREE STATION FOR FUTURE WORKING UNIT APPLICATION

At the outfeed of the machine:

SUPPORTING BRIDGE FOR FRONTAL HORIZONTAL BORING UNITS

AND FOR TOP VERTICAL UNITS MOD. PO-2/PN-2

=======================================================

Composed of rugged structures in horizontal and vertical electro-welded steel jointed, at the exit, to the machine base;

Both the supporting structures of the unit are provided with precision linear guides to allow the boring units manual positioning all along the bridges; the position is measured by magnetic strip.

Equipped with a steel table supporting the work pieces in exit provided with frontal and lateral reference fences, with a work pieces pushing system against fences and with a series of pneumatic pistons for the correct work piece positioning and for their clamping;

The base, supported on the bottom by pneumatic cylinders, is tiltable towards the inside of the machine for the processed elements outlet on the return or longitudinal outlet system.

On the vertical bridge:

CNC ROUTING UNIT FROM TOP

CNC ROUTING UNIT FROM TOP

The unit slides along the top bridge, cross wise and in a axial sense with respect to the piece; all three movements are independent driven by brushless motors and are interpolated by CNC; these movements are realised on precision linear guides by means of high precision ball screw;

The routing unit is composed with a electro-spindles driven by inverter. The working movement is programmed in function of the tool rotation direction and it is done on “clamped piece”.

The axial movement is provided with feeler pin

Spindle rotation speed : 12000 to 18000 Rpm

Motor capacity (each one) : 3,5/5,5 Kw inverter

Tool holding fixture : ER 40

Cutter diameter : min. 3 max. 25mm

Dust extraction

Required air speed : 30 m/sec

Air consumption : 1840 m³/h

The CNC routing unit is equipped with a pneumatic drilling unit installed on one side. Fitting bit with mandrel, 3800 rpm and drill capacity up to .

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. For orders up to $1,500, the credit card on file will be charged. For orders over $1,500, payment must be made via bank wire transfer, unless the buyer chooses to use a credit card, in which case a 3% processing fee will apply. For payment-related questions, please contact Sabrina Correa at 209-839-7707. Sales tax exemption documents must be emailed to [email protected] at the time of purchase for tax exemption consideration.