Holz-Her "Sprint 1321-2" Automatic Edgebander  Preview

Preview

Complete Woodworking Factory Auction - Chehalis, WA

Chehalis, WA

Starts In remaining

Complete Woodworking Factory Auction - Chehalis, WA ( Preview #71681127 )

After 50 years in business Aristocratic cabinets has ceased operations and is auctioning all assets. Aristocratic is well-known for high end cabinetry, panels and millwork featuring exotic woods. World-class machinery was used for their production. Two Biesse CNC routers, Selco beam saw, Holz-Her edgebander, Doucet return conveyors, Omal CNC bore/dowel machine, Weinig moulder, finishing machinery, hand tools, supplies, lumber, veneer, panels, forklift, delivery truck and much more.

-

Pick Up Location

151 Sturdevent Rd. Chehalis, WA 98532

-

Make

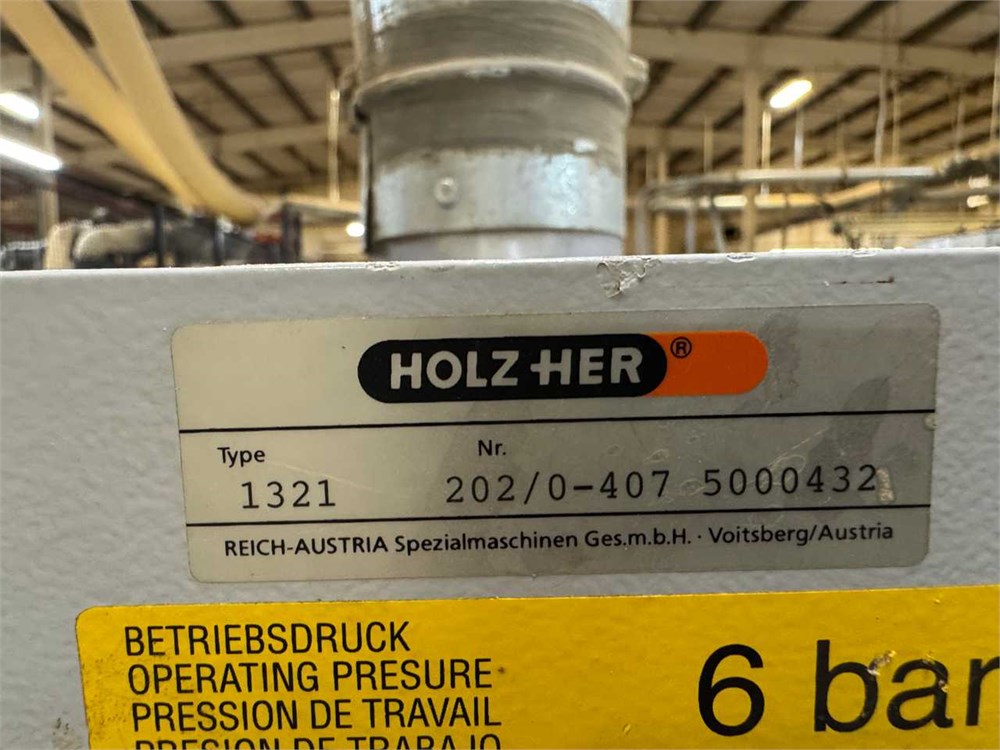

HolzHer

-

Model

Sprint 1321-2

-

Serial Number

202/0-407 5000432

-

Year

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Buyer Inspection Period

May 19, 2025 (9 am - 3 pm), other times by appointment

-

Load Out Period

May 27 - June 6, 2025 (by appointment)

-

Estimated Dimensions

240" x 48" x 68"

-

Estimated Weight

Approximately 5800 lbs.

-

Seller Comment

-

Load Fee

495.00

-

Lot Notes

-

page views

51

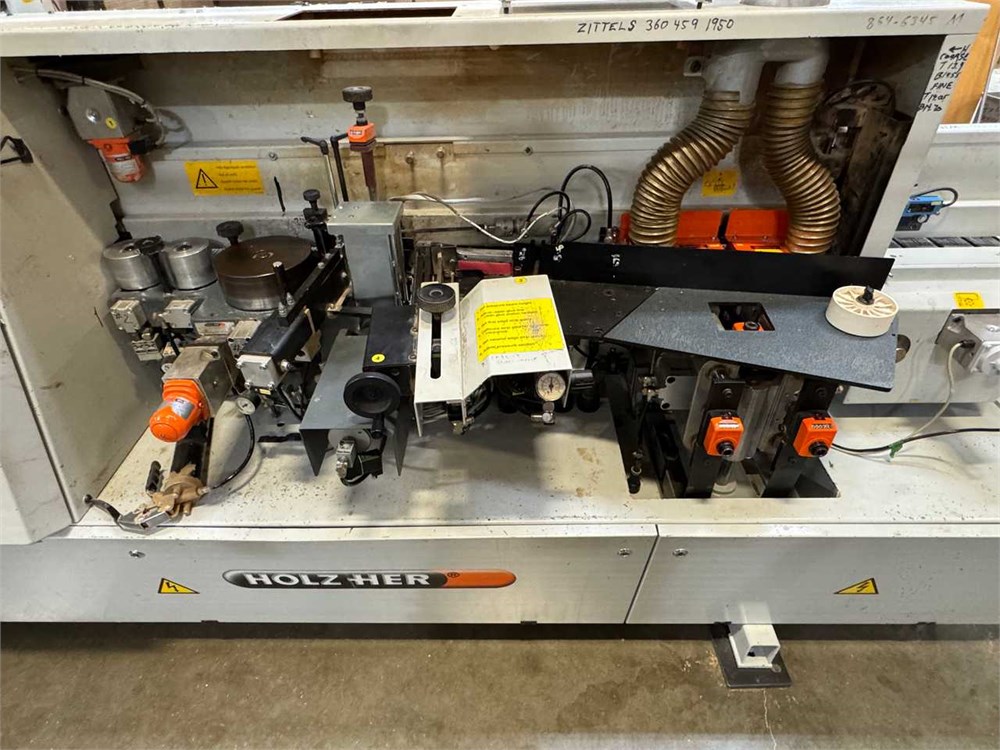

0.3 - 15 mm Thickness edgebanding capability (3 mm coil or 15 mm max. strip). 6 - 50 mm Panel thickness, workpiece width min. of 60 mm; workpiece Length min. 180 mm. Feed speed 12.5 MPM (41 FPM).

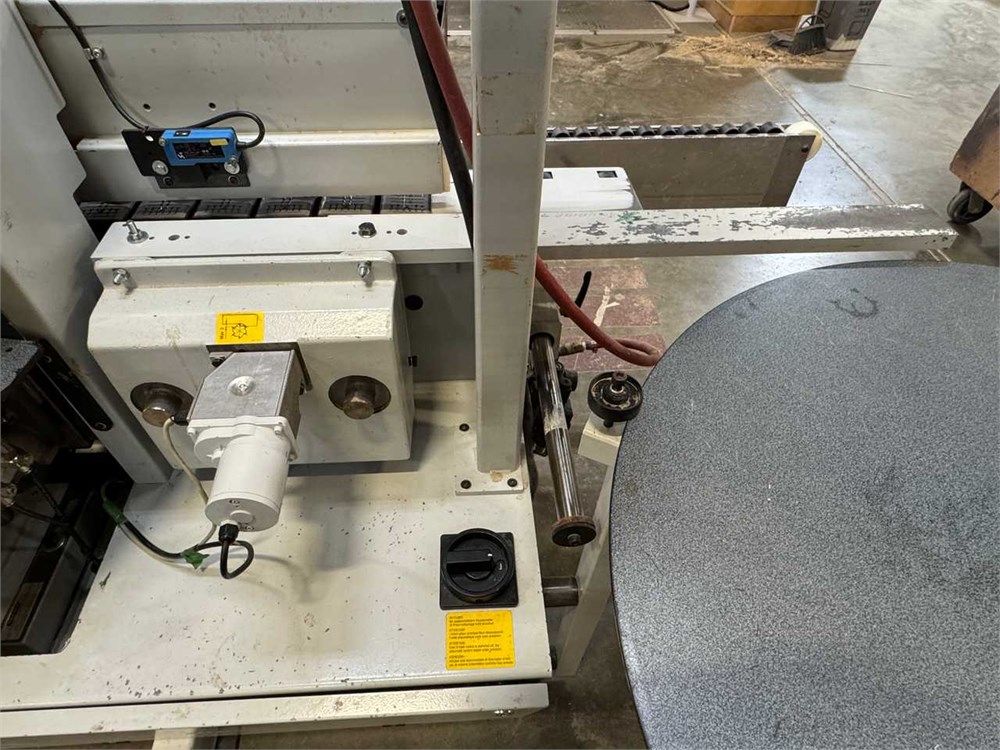

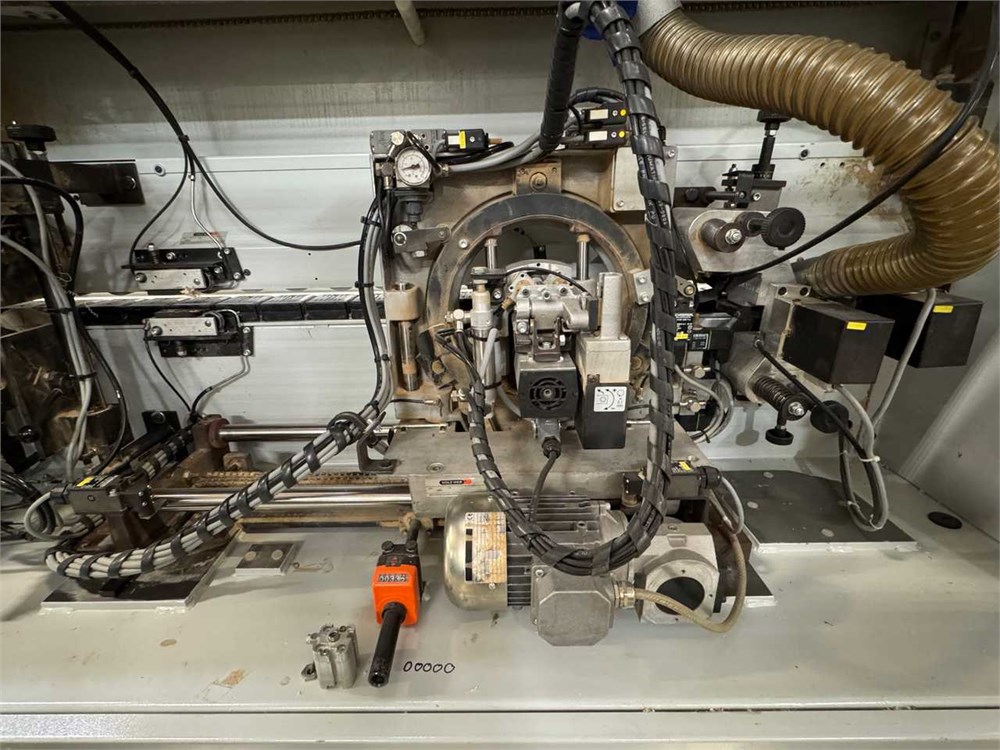

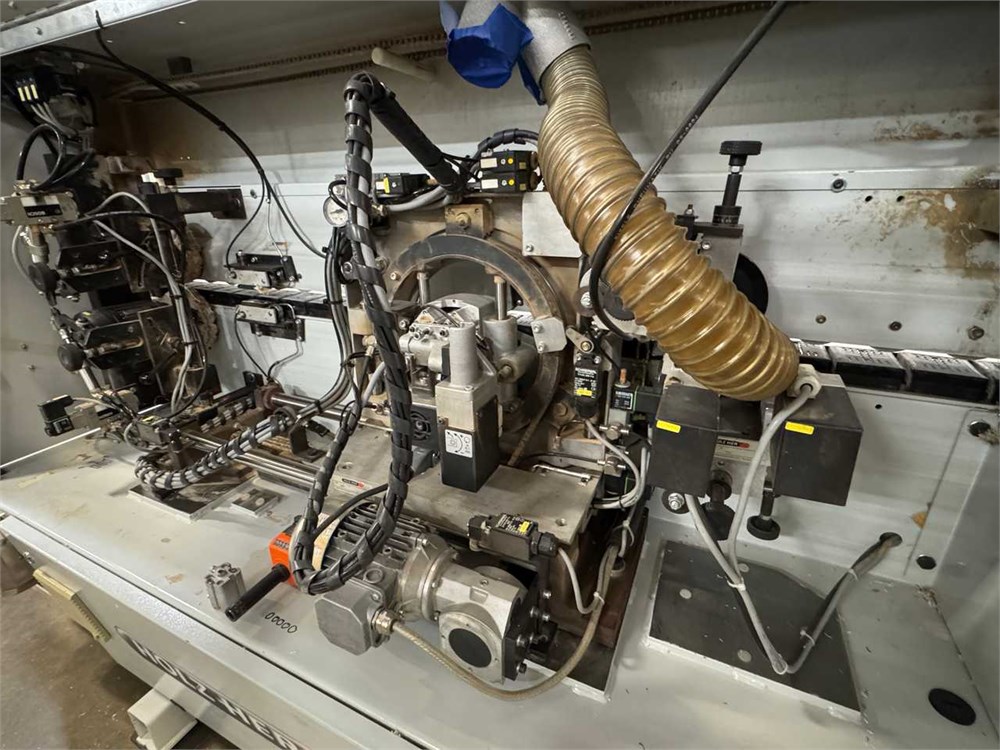

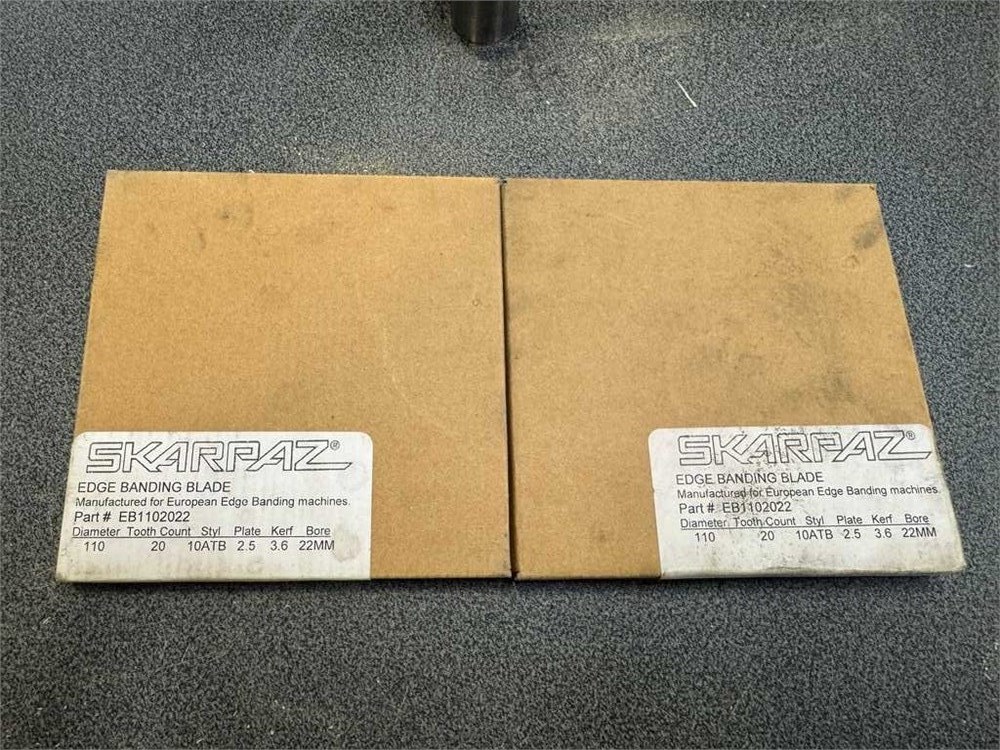

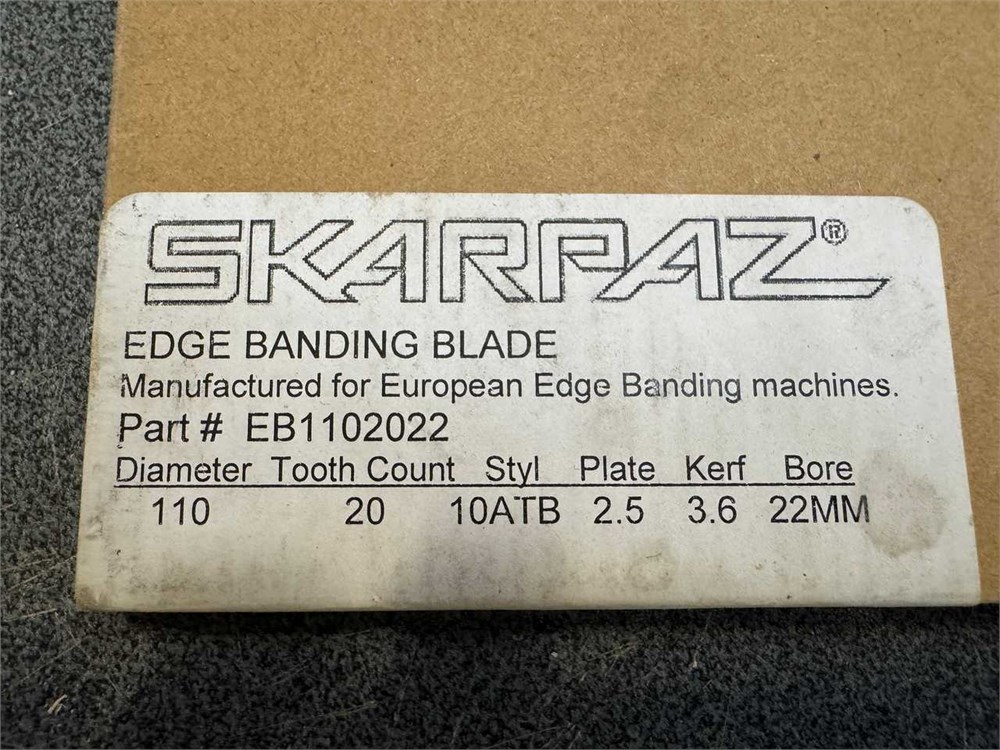

Pre-Milling Station "1961": (2) 2.0 kW - 12,000 RPM motors; With digital readouts for accurate positioning.

"1903" Edgestrip Magazine; (1) Universal magazine for solid edges, strips, and coiled material.

Utilizes motion detector to ensure accurate, trouble-free positioning of edge material; exclusive "Tractor-Belt feed System", edge guide equipped with automatic guillotine lock-out for safety, 3° approach angle allows easy feeding of large wood edges.

Pre-Milling Station "1961": (2) 2.0 kW - 12,000 RPM motors; With digital readouts for accurate positioning.

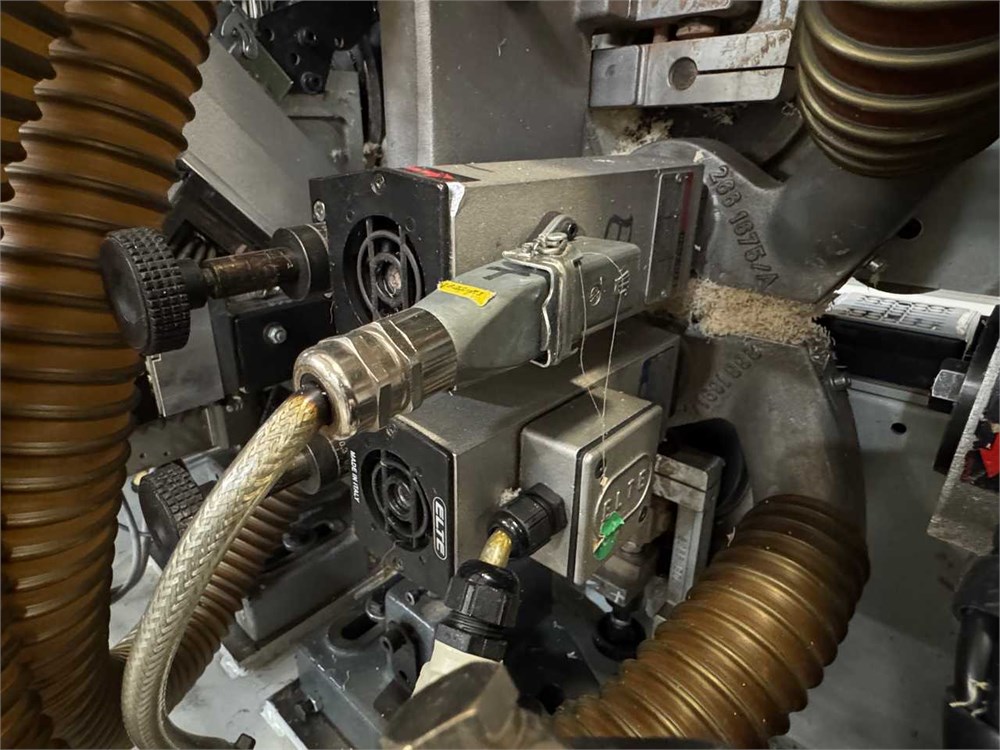

"1906" Gluing Station - Cartridge System with motorized, programmable glue height adjustment.

"1913" Pressure Section, servo motor controlled with (1) large driven roller & (2) cantered idle rollers.

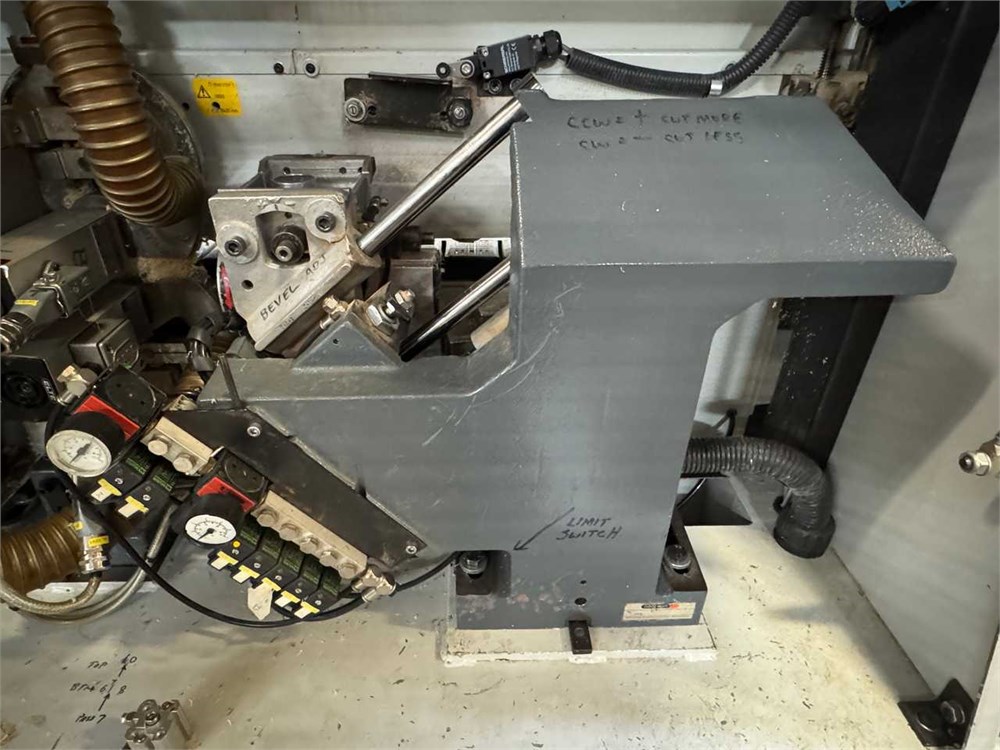

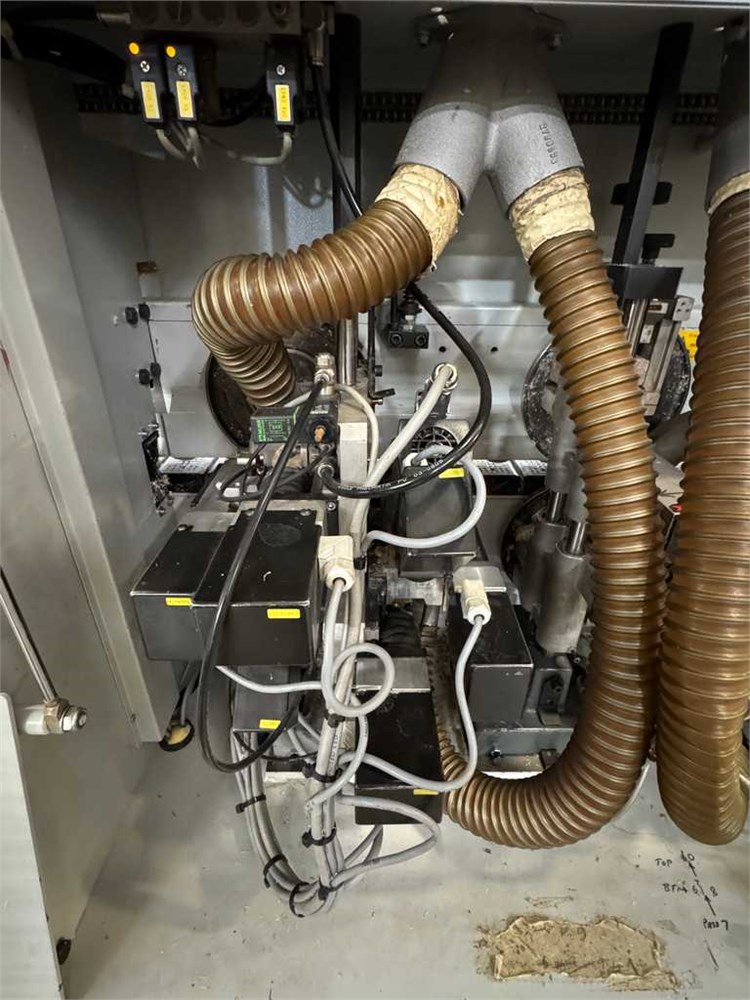

End Trimming, "1918": Front & rear with (0.35 kW - 9,000 RPM motor each), Uni-Point axis for no re-indexing when changing from flush to bevel end trim (0° - 10° bevel),"PCS" Pneumatic Changeover from flush to bevel from control panel.

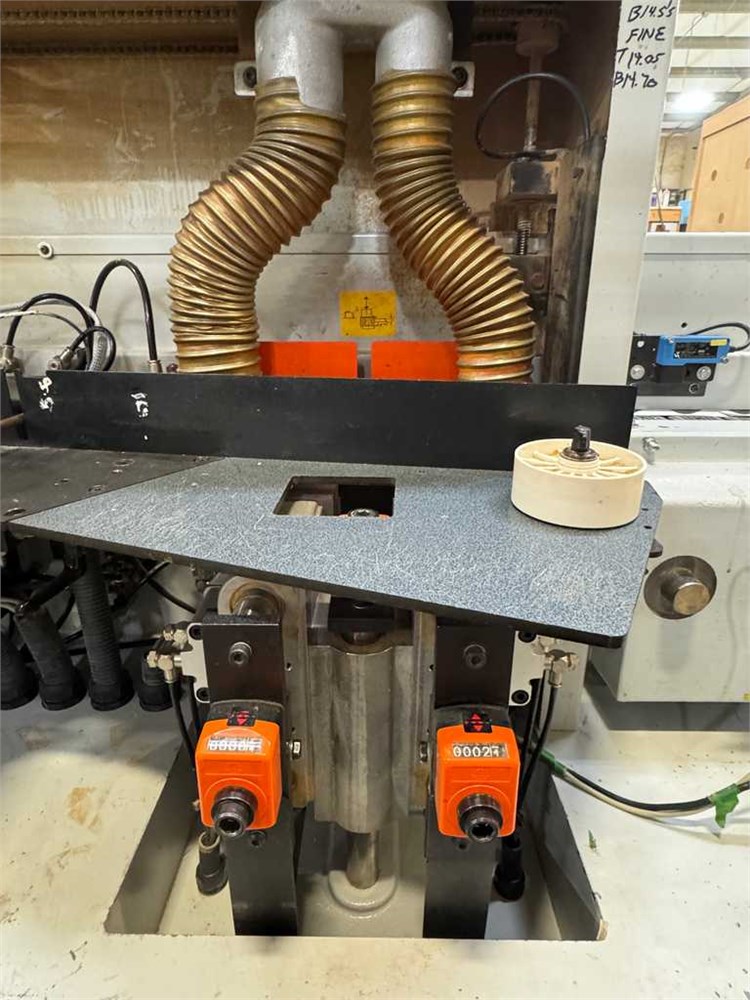

Flush/Pre-Trimming Unit "1823": Top & bottom with (0.6 kW - 300 Cy HF motors 18,000 RPM Motor ea.), SIKO digital readouts.

Flush/Bevel/Radius Trimming Unit "1824": Servo controlled top & bottom with (0.6 kW - 18,000 RPM each motor).

Profile Scraping Unit "1929": Top & bottom for thick PVC scraping, reversible insert carbide knives, equipped with air-jet blowers; Chip Collector Box.

Corner Rounding Unit "1983": 1-Motor unit for edges up to 3 mm edge thickness.

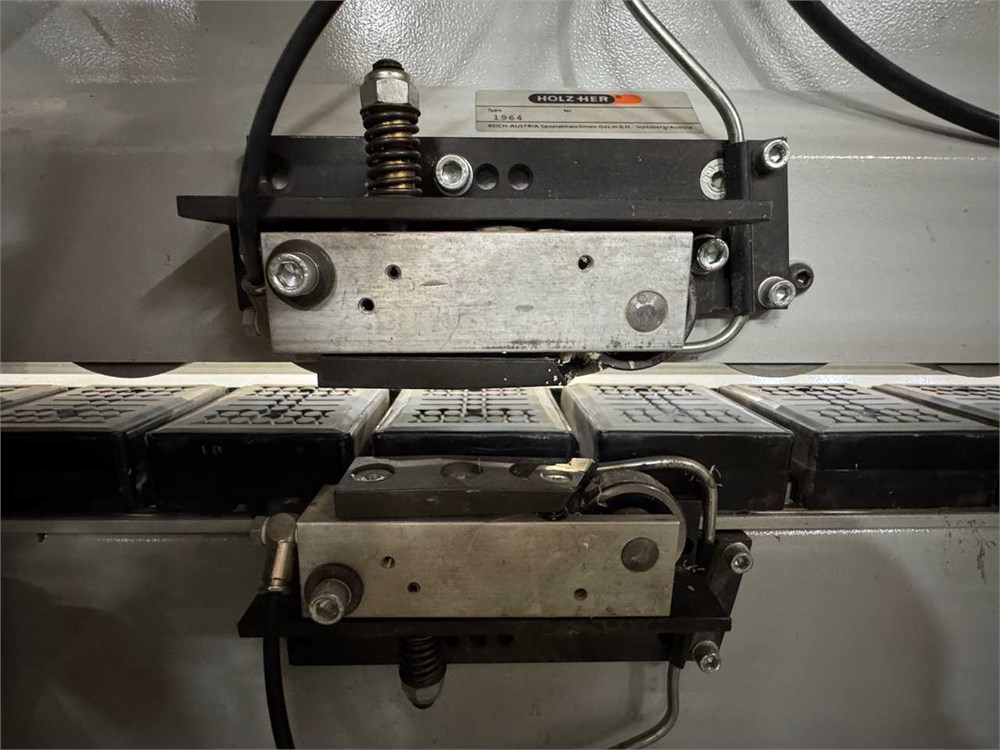

Flat Glue Scraping Unit 1964, top/bottom plc controlled to remove potential glue squeeze-out on the surface of the panel.

Buffing Station"1940": Top & bottom, with timed pneumatic plunge controll, adjust in any direction (vertical tilt is 0° - 5°, horizontal Swivel is 0° - 20°); 1,440 RPM wheel rotation.

Programmable Logic Control (PLC) with windows like user interface for edge feed, glue application, end trimming, flush trimming, radius trimming, scraping, corner rounding, and buffing. Programs can be easily created and recalled at will; color screen with graphic interface makes programming easy, icon of each unit may be brought up on the screen to show the operator the status of the unit and the parameters which can be programmed. Edgebander can be operated manually when required, without the necessity to write a program.

Microprocessor for line control & glue temperature, 10 KVA static frequency changer, outboard panel support, and sound enclosure w/interior lights over enclosed workstations of the machine, & used tooling on the stations.

Return conveyor is not included - See lot #018

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available