Biesse "Rover A 1659" 5-Axis CNC Router  Active

Active

Biesse "Rover A 1659" 5-Axis CNC Router - Littleton, CO

Littleton, CO

- Current Price : $13,350.00 USD ( ) No Reserve

- 8 Bid(s)

- High Bidder: A****r

Biesse "Rover A 1659" 5-Axis CNC Router - Littleton, CO ( Active #67619810 )

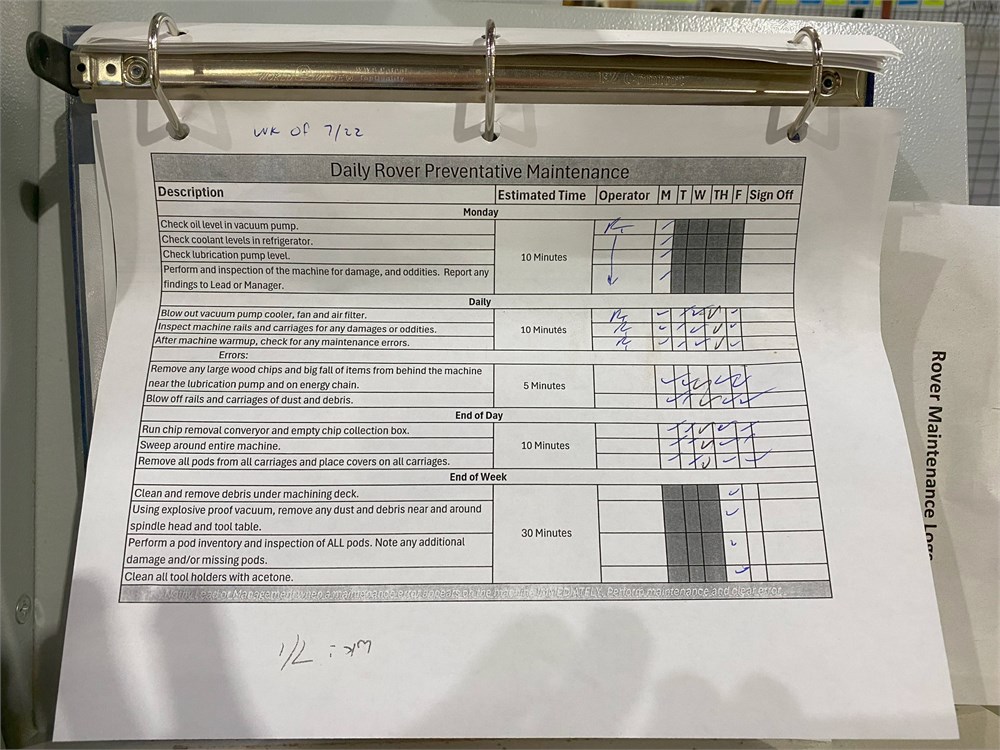

A Furniture maker in the greater Denver, CO area is auctioning a Biesse "Rover A 1659" 5-Axis CNC Router no longer required for continuing operations. Please call me directly with any questions.

-

Item Location

Littleton, CO

-

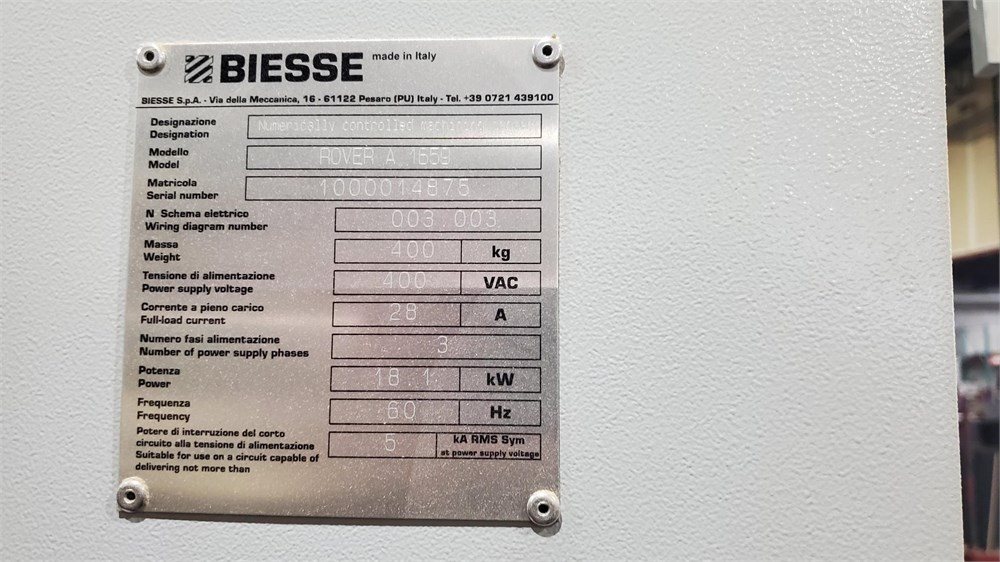

Make

Biesse

-

Model

"Rover A 1659"

-

Serial Number

1000014875

-

Year

2016

-

Phase

3 PHASE

-

Voltage

400

-

Inspection Date

By Appt. Only - Please contact: Thomas Aronson [email protected]

-

Final Removal Date

See Homepage page for removal dates

-

Estimated Dimensions

-

Estimated Weight

12,000 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal. By appointment ONLY!

-

Load Fee

-

Lot Notes

Included as a spare: New factory rebuilt Spindle!

-

page views

1139

Biesse "Rover A 1659" 5-Axis CNC Router SEE VIDEO

7.4 Hp Liquid Cooled HSK 63F 5 AXIS Main Spindle 24,000 RPM Max

NC Controlled 12 Position Dust Hood

C AXIS - Full rotation - 18RPM

B AXIS - Full rotation - Non-stop

Maximum Angle Undercut 10 Degrees

B axis rotation @ 16RPM

BH29 Boring Head W/Auto-Lube - VS Control to 6K RPM

Grooving saws - 1 in X - 1 in Y

13 Vert Spindles - 8 in X - 5 in Y

5 x Horizontal Double Output Spindles - 3 in X - 2 in Y

1 Sawblade 120mm DIA

16 Position Onboard Revolving Tool Changer

Tool Length Presetter

Additional Z carriage for back operating units controlled by an independent Z axis.

X = 5920 mm

Y = from 1580 to 1660 mm, according to working conditions

Z = 200 mm - 5 axes unit and boring unit, with modules H=74 mm

Z = 245 mm - 5 axes unit and boring unit, with modules H=29 mm

X = 6346 mm; Y = 2294 mm; Z1 = 515 mm: Z2 = 371 mm.

Unit Option: To allow panel panel with dimension in Y up to 2100 mm.

Unit Option: The NC lifts the safety strips during the phases of loading/unloading and operating unit positioning.

Panel Supports (NC Controled and Positioned)**

For safe loading/unloading of panels

8 ATS panel supports

SA working table (Set-Up Assistant)** Manual working table positioning system aided by direction and position lights.

Vacuum 300 m3/h at 60 Hz

BSolid Software - 5 AXIS Machining

Belt Conveyor For Chip Removal

MultiTap Transformer

Remote keypad

Centralized Automatic Lubrication

Light Barrier Safety System

Pendulum machining capable

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration.