Morbidelli "Universal 3615" CNC Router w Load/Unload & Rake  Ended

Ended

Jakobe Furniture - Complete Plant Closure - Kansas City, KS

- Winning Bid : $35,150.00 USD Sold

- 136 Bid(s)

- High Bidder: C****1

Jakobe Furniture, LLC - Complete Plant Closure - Kansas City, KS ( Closed #29092465 )

Complete plant closure with late model machinery. 250+ lots featuring: SCM Pratix S15 CNC Router, Kentwood R320XM Gang Rip Saw, SCM Sandya 16S Wide Belt Sander, SCM Sandya S600 RCS Wide Belt Sander, Holzma Profiling CH12 Beam Saw, Morbidelli Universal 3615 CNC Router, Plus Much More!

-

Item Location

450 South 55th St Kansas City, KS 66106

-

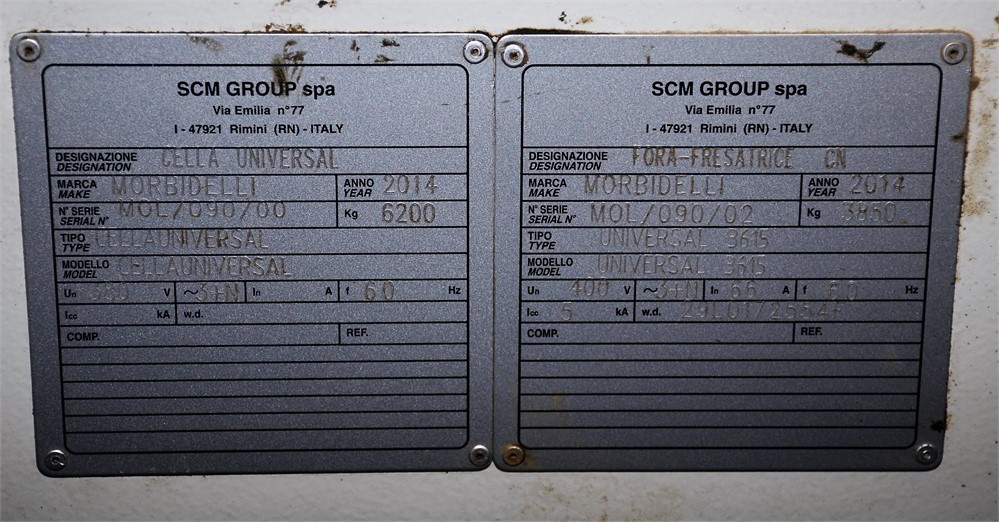

Make

Morbidelli

-

Model

Universal 3615

-

Serial Number

MOL/090/02

-

Year

2014

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Inspection Date

Friday Sept 17 2021 or by appointment. Contact Mike Arnott 913-333-8396

-

Final Removal Date

Thursday Sept 30th 2021

-

Estimated Dimensions

Foot print 50' long x 16' wide, 9' tall

-

Estimated Weight

15,000 Lbs (approx) largest piece - 3 total pieces

-

Seller Comment

Contact Always Trucking for a shipping quote 541-608-6532

-

Load Fee

A rigger is required. Buyer's Responsibility for Break-down, loading and removal.

-

page views

3866

Universal 3615 CNC Router:

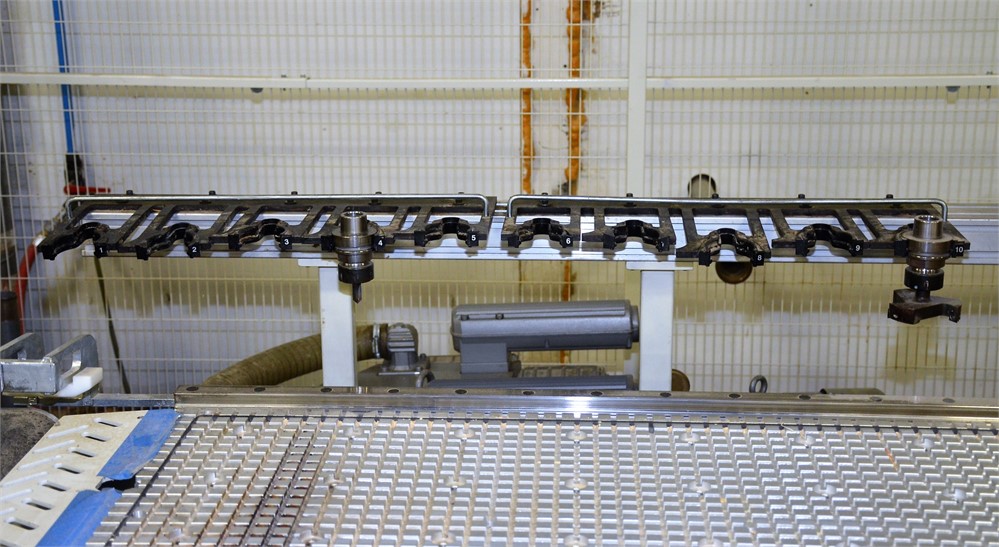

5' x 12' Traveling "Bridge Gantry", stationary aluminum grid "MATRIX" table with square grid pattern for fixturing parts; (8) vacuum zones controlled by electronic switches. 200" L x 96" W x 106" H overall dimensions.

Grid pattern allows use of vacuum pods or closed cell rope gasketing material and use of spoilboards for "nested base machining", part location pop-up pins mounted on the table perimeter.

"X" Axis is 143.7" (3,686 mm); "Y" axis is 61.2" (1,555 mm); "Z" axis stroke is 9.4" (240 mm); max. material thickness 5.9" (150 mm) (5.1" / 130 mm when using off-loading system...not included) .

"X" Axis 229 FPM (70 MPM), "Y" axis 197 FPM (60 MPM) "Z" axis at 49 FPM (15 MPM); closed loop AC Servo drive system.

High precision "Rack & Pinion" system in "X" & "Y" axis & ground ball screws "Z" axis; all axes ride on extra large precision profile linear guide-ways.

3 HP (2.2 kW) motor, variable speed from 1,000 - 6,000 RPM; (12) independent vertical spindles on 32 mm centers, (7) spindles in "X" axis & (5) spindles in "Y" axis.

(6) Horizontal spindles with (2+2) in "X" axis & (1=1) in "Y" axis; (1) "X" axis grooving saw for max 120 mm dia blade.

(1) 12 HP (9 kW) Air cooled electro spindle with HSK F63 adaptor; variable spindle speeds from 1,500 - 24,000 RPM;

(1) 10-Position ATC tool rack mounted at the rear of the machine base.

PC Front-End with: "XILOG Plus" + Windows "XP PRO" operating system; 17" high resolution LCD flat-screen.

USB Ports, serial ports RS-232 & RS-242 & Ethernet adaptor; programs can be transferred via disk or downloading by wire is possible; all computer components are mounted on a mobile stand.

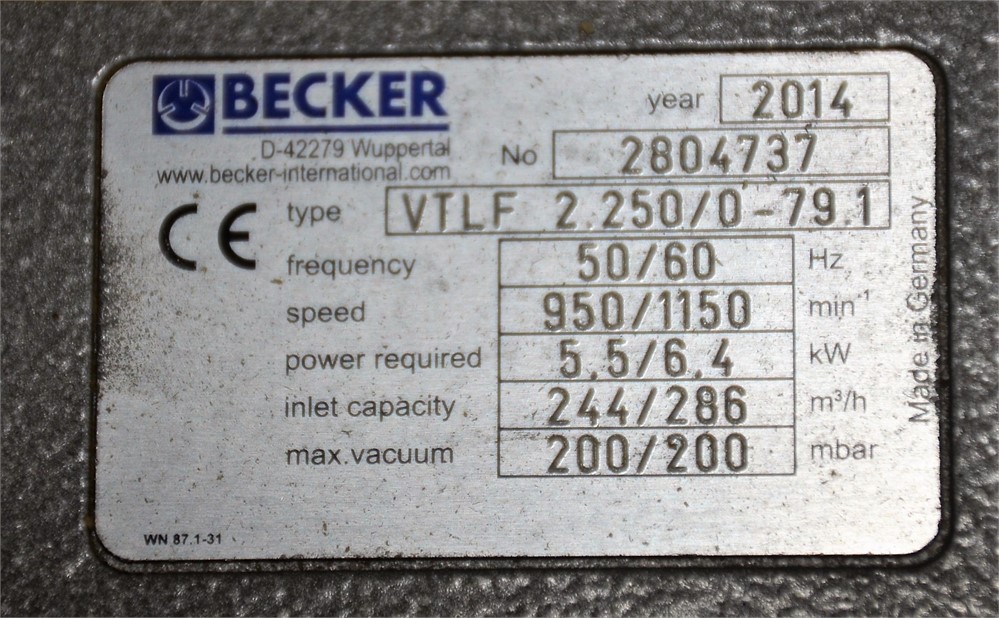

(2) 300 m³/Hr "BECKER" Vacuum Pump; Touch probe measuring device for tools; Electronic detecting devices for "spoil board" thickness and tool length; hand held remote control pendant; automatic lubrication system; 208/230/460 auto-transformer; safety enclosure around the spindle carriage; photo-cell safety sensors & perimiter fencing; documents & manuals.

Automatic infeed

176" L x 80" W x 72" H overall dimensions, Scissor lift, Photo eye at infeed onto machine. Three (3) side mounted vacuum cups and rollers, control box for manual or automatic operation.

Loading device with three (3) vacuum cups for loading panels onto machine, automatic dust blast gates to clean table in advance of next panel

Automatic outfeed:

192" L x 65" W x 40" H overall dimensions, 62" belt width, photo eye at end of belt, side fences, control box for manual or automatic operation.

Installed and extra tooling

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Mike Arnott 913-333-8396 [email protected].

For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased.

Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed

Local riggers

Haggard Hauling - Aaron 816-221-7840

Olinger Rigging & hauling - Jack 816-266-7981

Huddleston Machinery Moving, Inc PH: 816-231-4147 [email protected]

Belger Cartage Service 800 873 2547

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.