HolzHer "Accura 1554 4.0 Automaric" Edgebander (2019)  Active

Active

CabinetWorks Complete Plant Auction (Day 1 of 3)

Thompsontown, PA

- Current Price : $5,000.00 USD ( ) No Reserve

- 1 Bid(s)

- High Bidder: n****e

CabinetWorks Complete Plant Auction (Day 1 of 3) -Thompsontown, PA ( Active #69211257 )

Day 1 More Lots currently being added! Featuring: Biesse "Rover B FT 1536" CNC Machining Cell - Load/unload (2022), Schelling "FH 6 330" Rear Load Beam Saw, Biesse "Skipper 100L" CNC Panel Machining Center, Weinig "Opticut S50" Optimizing Crosscut Saw, HolzHer "Acura 1554" Edgebander, Italpresse "SP/1-A" Feed Thru Case Clamp, Plus Much More!

-

Pick Up Location

Thompsontown, PA

-

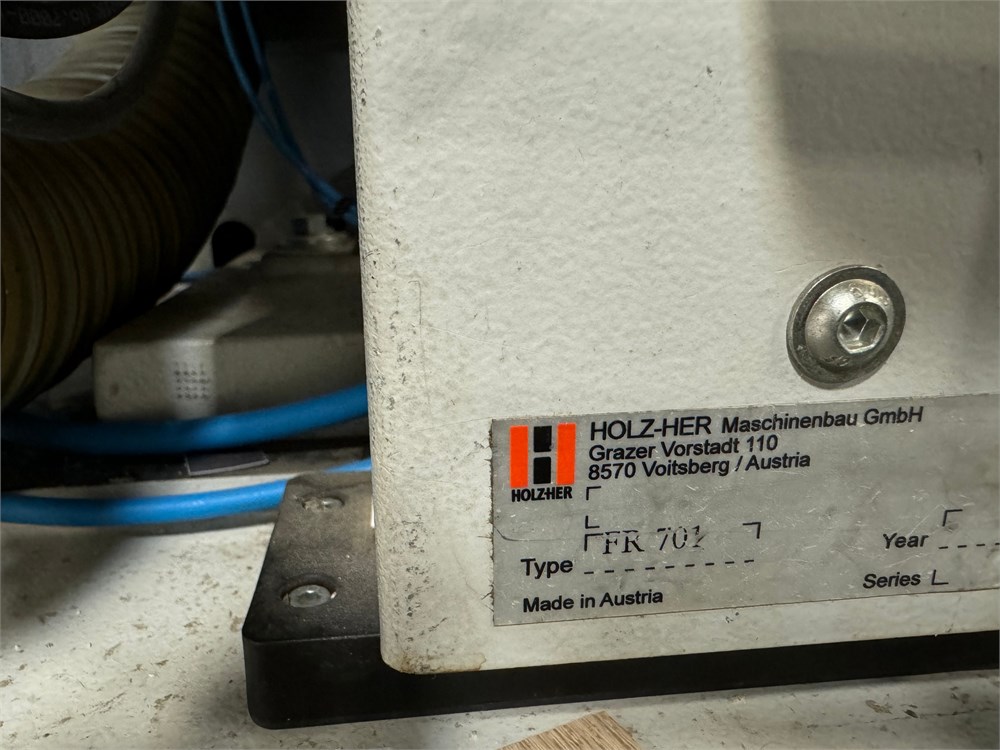

Make

Holzher

-

Model

Acura 1554

-

Serial Number

See Plate

-

Year

2019

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Buyer Inspection Period

March 12 and March 13, 2025 (9 am - 3 pm) or by appointment

-

Load Out Period

March 24 - April 7, 2025 (by appointment) unless other arrangements made in advance

-

Estimated Dimensions

4' x 25' x 6'H

-

Estimated Weight

6,000 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal.

-

Load Fee

-

Lot Notes

Still in use - See Video

-

page views

478

HolzHer "Accura 1554 4.0 Automaric" Edgebander (2019)

Edge thickness min./max. 0.4 - 3 mm (0.02 - 0.12") for coiled material, 8 mm (0.315") max for strips.

Panel thickness 8 - 60 mm (0.315" - 2.36"); workpiece width min. 60 mm (2.36"); workpiece length min. 140 mm (5.5"); Feed speed 10 - 20 MPM (33 - 66 FPM).

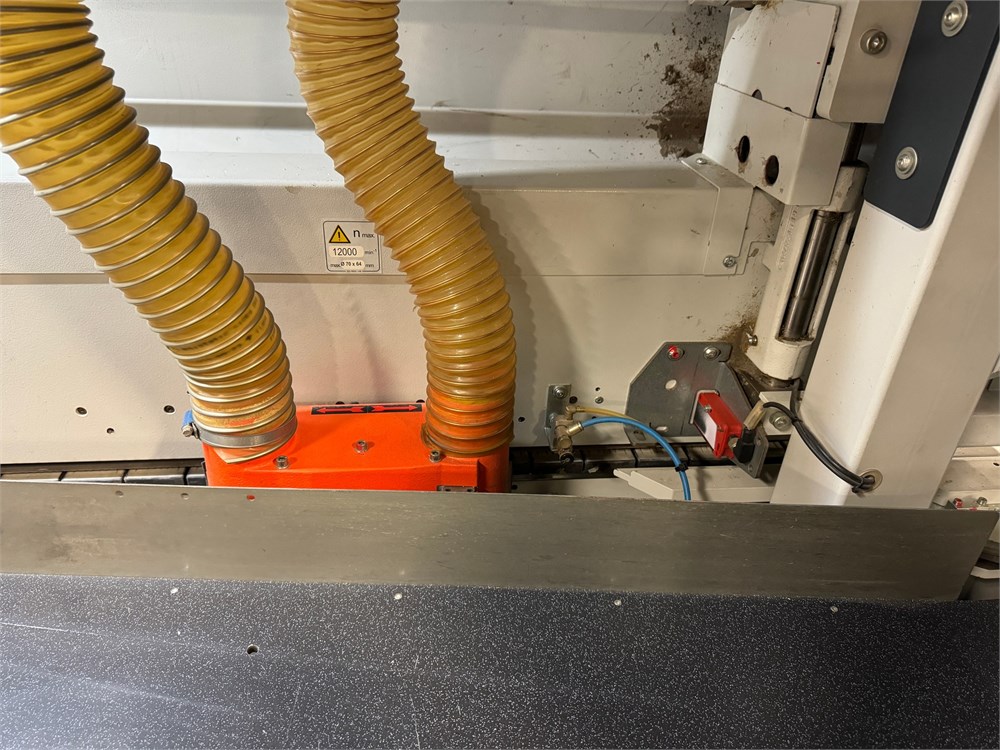

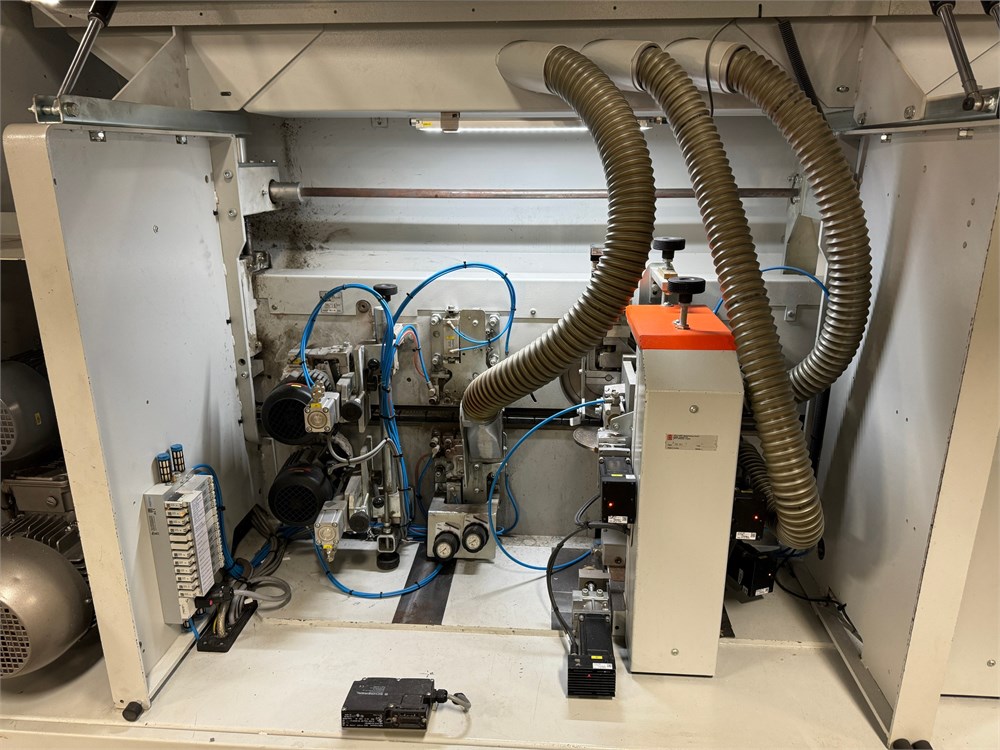

Pre-Milling Station "1802": 2x 1.2 KW (1.6 HP) - 12,000 RPM motors.

Edge Magazine "1901": for coil and strip processing, utilizing motion detector to ensure accurate, trouble-free positioning of edge material; exclusive "Tractor-Belt feed System", edge guide equipped with automatic guillotine lock-out for safety, 3° approach angle allows easy feeding of solid wood edges.

Pressure Section: (1) large driven (synchronized with feed-speed)roller and (3) cantered idle rollers, servo adjustment.

GLUING SYSTEM "GJ 301" (Glue Jet)... Processes "EVA" or "PUR" Glue in Cartridge.

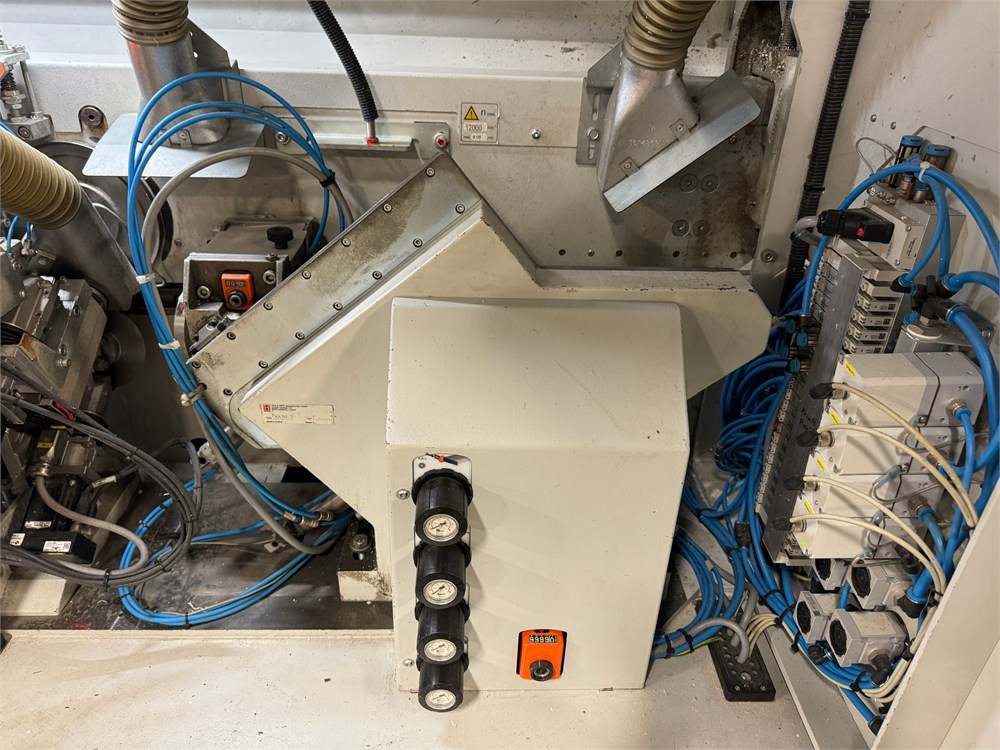

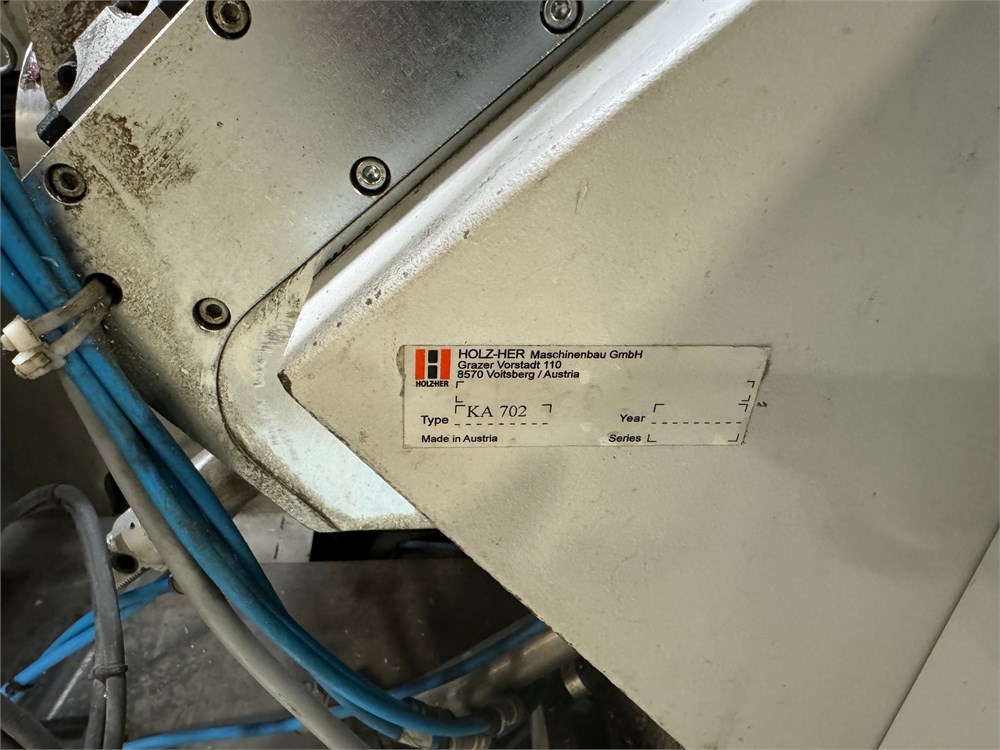

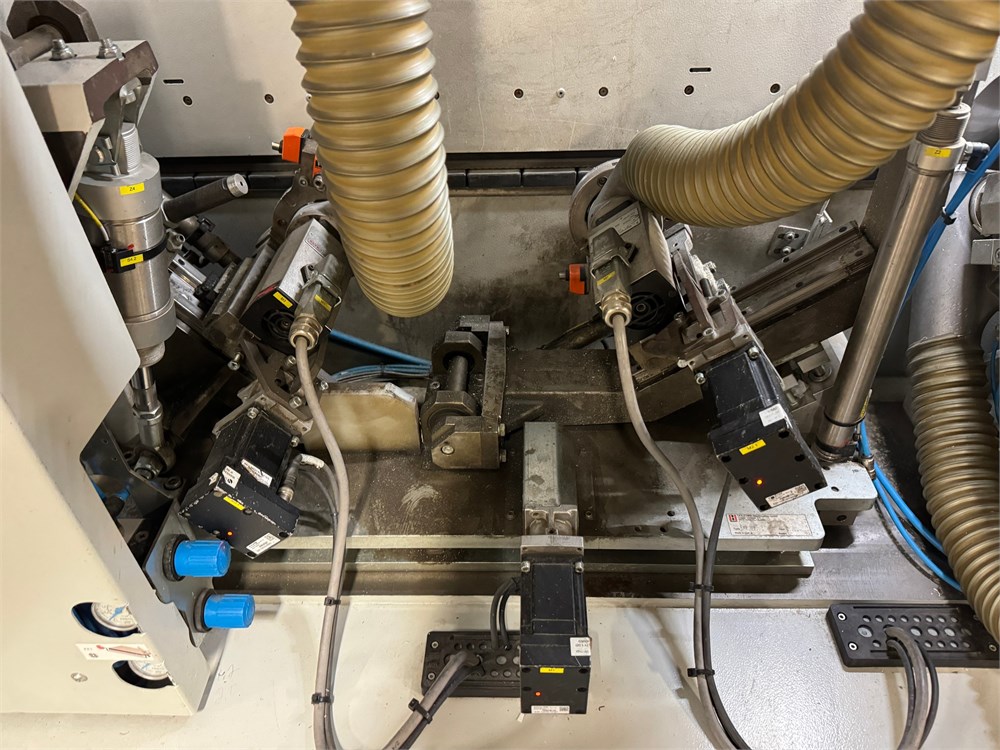

End Trimming Unit "KA 702": Front & rear 2 x 0.45 KW (0.6 HP) - 9,000 RPM motor each, uni-point swivel-axis for no re-indexing when changing from flush to bevel end trim (0° - 10° bevel),"PCS" programmable pneumatic change-over from flush to bevel.

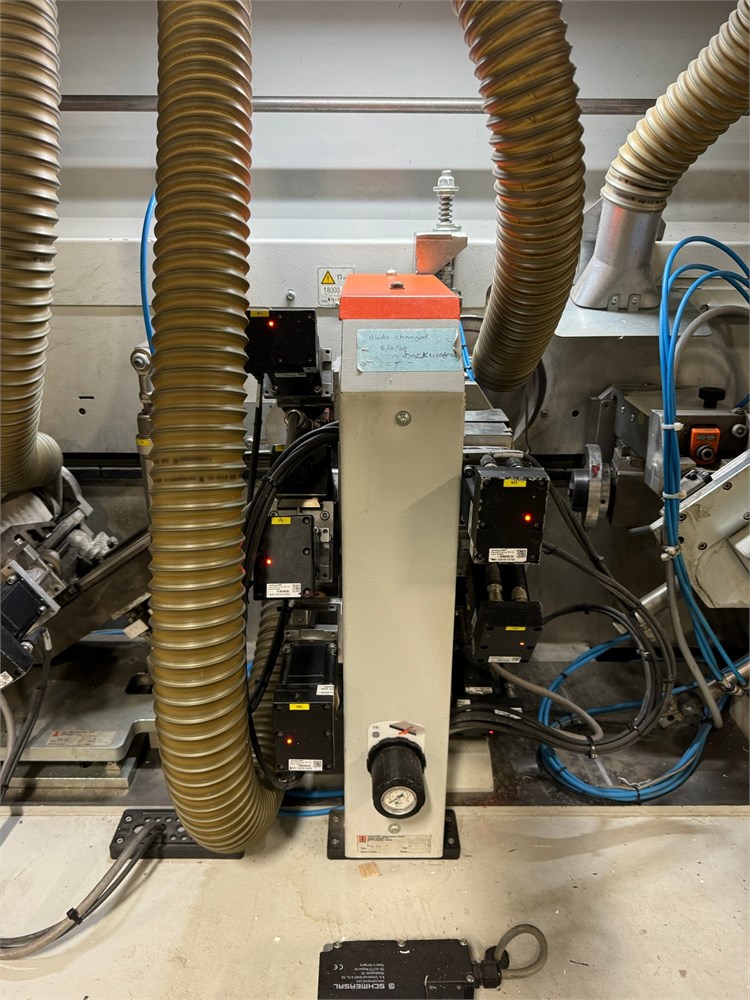

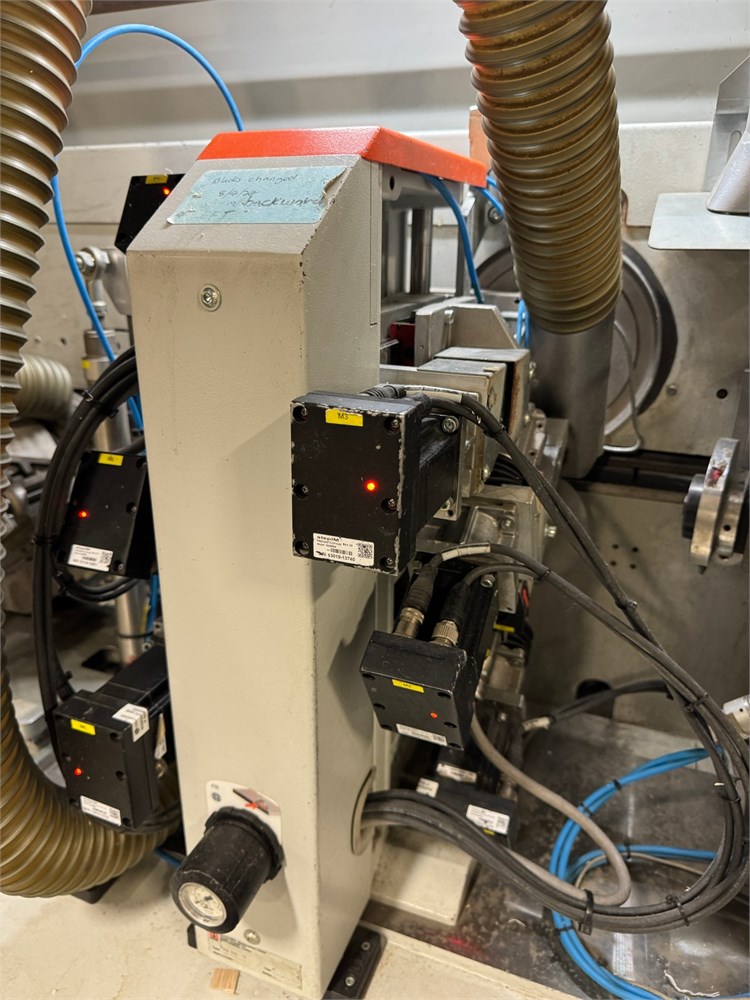

Flush/Bevel/Radius Combination Trimming Unit "FR 701": Flush 6 mm, radius 3 mm trimming, servo controlled, 2 @ servo motors (1) for horizontal copy wheel & (1) for tool spindle position) programmable top & bottom unit 2 x 0.65 KW (0.88 HP) - 12,000 RPM each motor.

Uni-Point design with no second adjustment, pneumatic, programmable tilt action for changing the degree of bevel, digital counters for vertical copy wheel position and pneumatic air cylinder for in/out pre-positioning of trimming motor.

Corner Rounding Unit "FF 701": (2) Motors 0.22 KW (0.30 HP) - 9000 RPM for up to 3 mm edge thickness and work-piece thickness min./max. 12 -60 mm (0.473 - 2.362"), max. feed speed 10 MPM (33 FMP).

Profile Scraping Unit "ZK 501": Top/Bottom, servo motor controlled/programmable knife position, vertical copy wheel adjustment with quick setting spindle.

For PVC edges, reversible insert carbide knives, equipped with air-jet blowers and chip collector box.

Glue Scraping Unit " FK": Flat surface, top/bottom, ball bearing guided and pneumatic controlled. Reversible - replaceable knife inserts and blow-off nozzles.

Buffing Station: Top & bottom, 2 x 0.09 KW (0.25 HP)buffing motors with 150 mm ( 6.0") cloth buffing wheel diameter.

Adjusts in any direction (vertical tilt is 0° - 5°, horizontal swivel is 0° - 20°); 1,440 RPM wheel rotation.

"EDGE CONTROL TOUCH" offers self-explanatory, graphic pictograms for simple user guidance. 18.5" TouchScreen, with Brilliant graphic display of machining processes. Simple operation & ndash; rotating and swiveling control panel at eye height.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available