SCMI "Olimpic K 560" Edgebander (2017)  Active

Active

Coastline Cabinetry & Custom Millwork - Fort Meyers, FL

Fort Myers, FL

- Current Price : $4,800.00 USD ( ) No Reserve

- 9 Bid(s)

- High Bidder: G****z

Coastline Cabinetry & Custom Millwork ( Active #68994638 )

Over a 140 Lots of Late model machinery & more...including: SCMI "Morbidelli X200 Cell" CNC Machining Center (2022), (2) Coima "SHK5" Dust Collectors (2021), SCMI "Olimpic K 230 EVO" Edgebander (2022), Kaeser "Aircenter SK 20" Air Compressor Center (2022), Gannomat "Concept 70 ECO" Case Clamp,SCMI "Olimpic K 560" Edgebander (2017), Edgetech "CTS740" Countertop Saw, Edge Automation "ERC" Return Conveyor System, Evans/Midwest Laminating Line, VAC-U-CLAMP "FT 900" Thermoforming Vacuum Press, Toyota "7FGCU25" Forklift, Coima "SHK3" Dust Collector.

-

Pick Up Location

Fort Meyers, FL

-

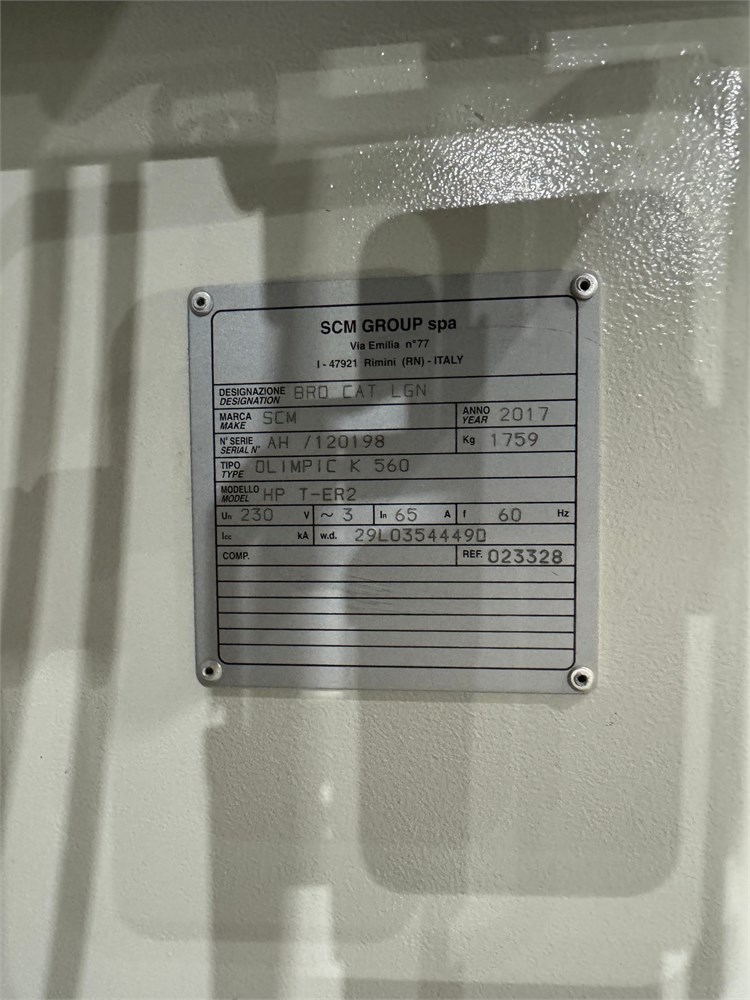

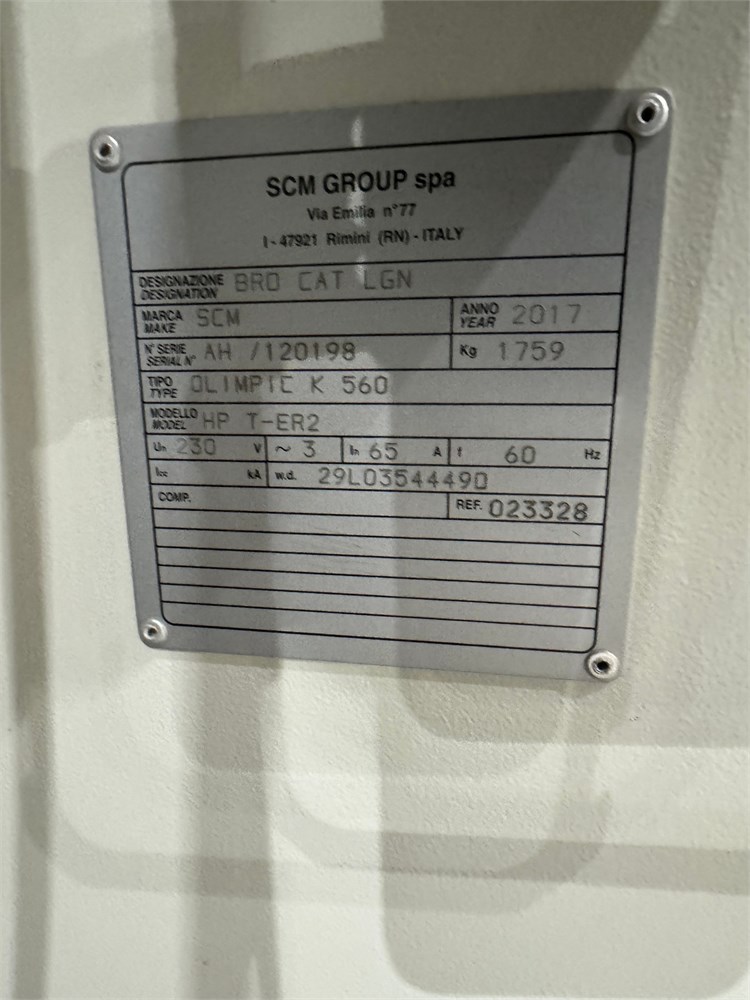

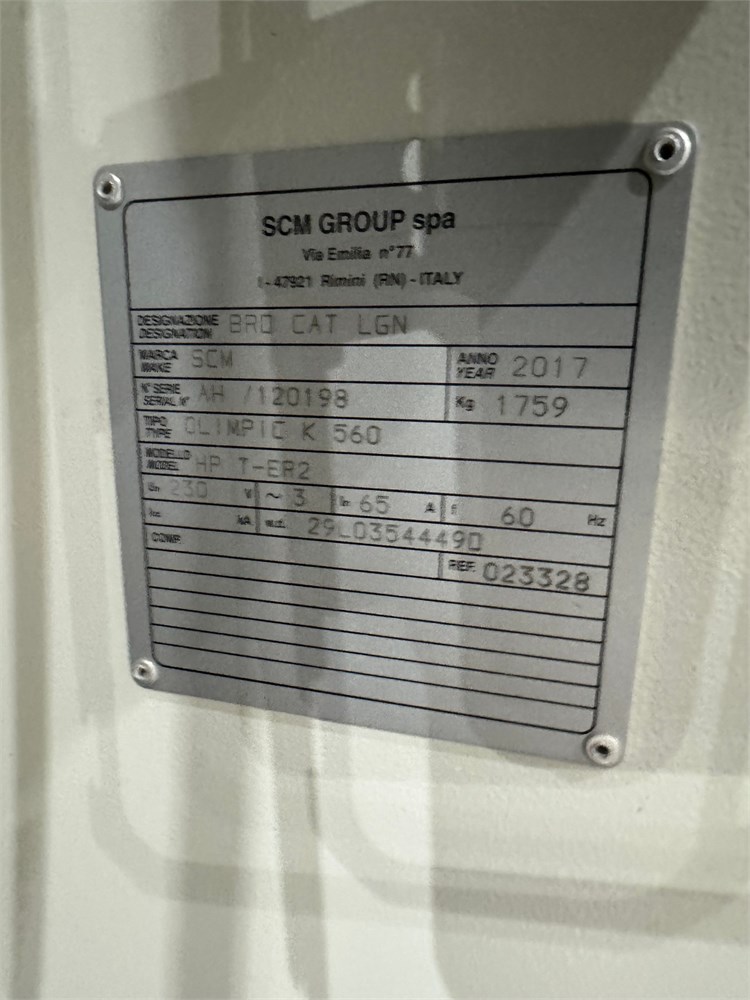

Make

SCMI

-

Model

"Olimpic K 560"

-

Serial Number

AH/120198

-

Year

2017

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Buyer Inspection Period

Open House will be February 5, 2025 9Am - 3PM. No appt. Needed. Kirk Gass 925-250-8248 (text ok)

-

Load Out Period

February 10-13, 2025

-

Estimated Dimensions

190" x 48" x 68"

-

Estimated Weight

4,000 Lbs

-

Seller Comment

A non-negotionable loading fee has been established. This includes loading onto a flat bed trailer. Paletization or other Services available for an extra fee.

-

Load Fee

895.00

-

Lot Notes

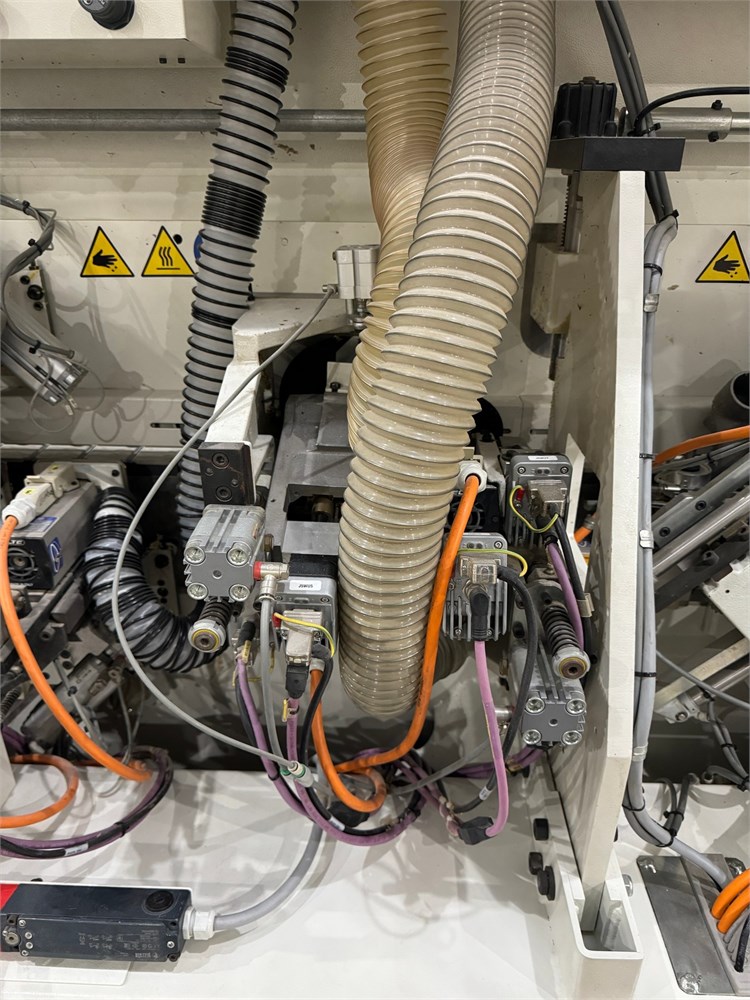

Dust manifolds included.

-

page views

412

SCMI "Olimpic K 560" Edgebander (2017)

Edge Capacity, 0.4 to6 mm (0.016to 0.25")for strip feeding.

Min. Panel width60 mm(2.375");Min Panel length 140 mm(5.5"). Min./max. Panel thickness 8 -54 mm (0.375" - 2.125"); Minimum distance between panels600 mm (24").

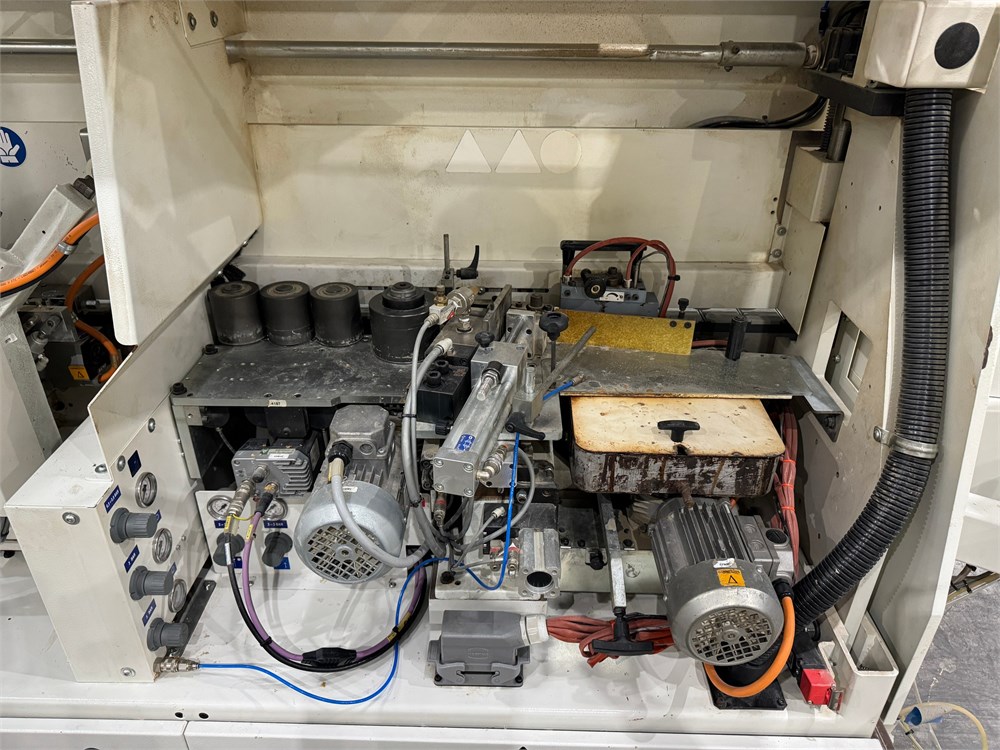

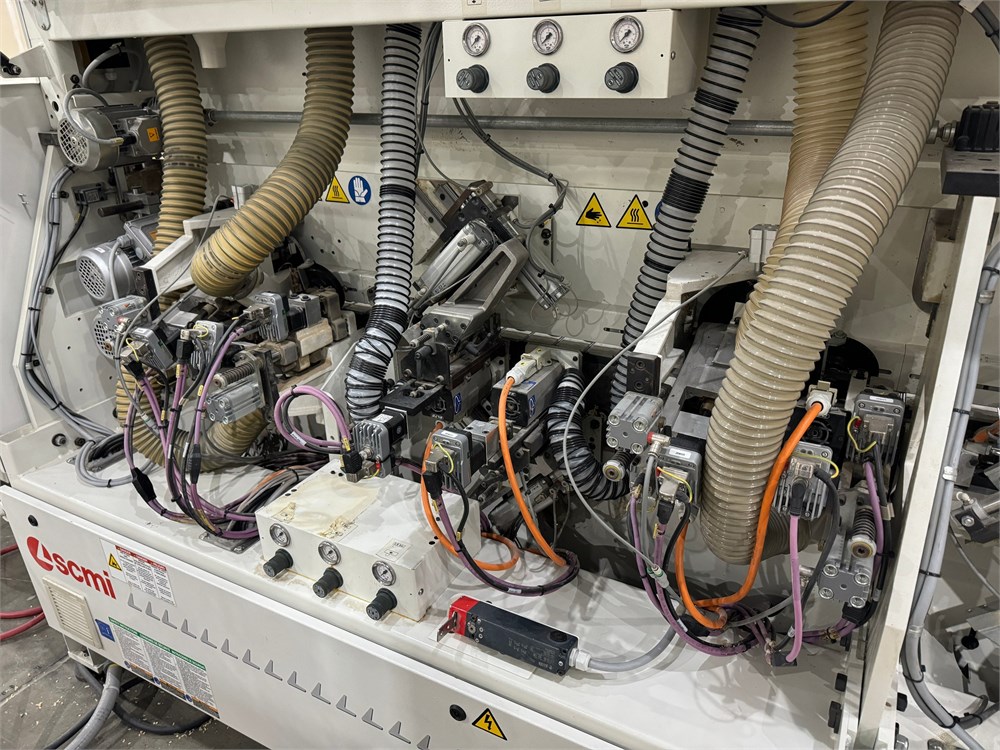

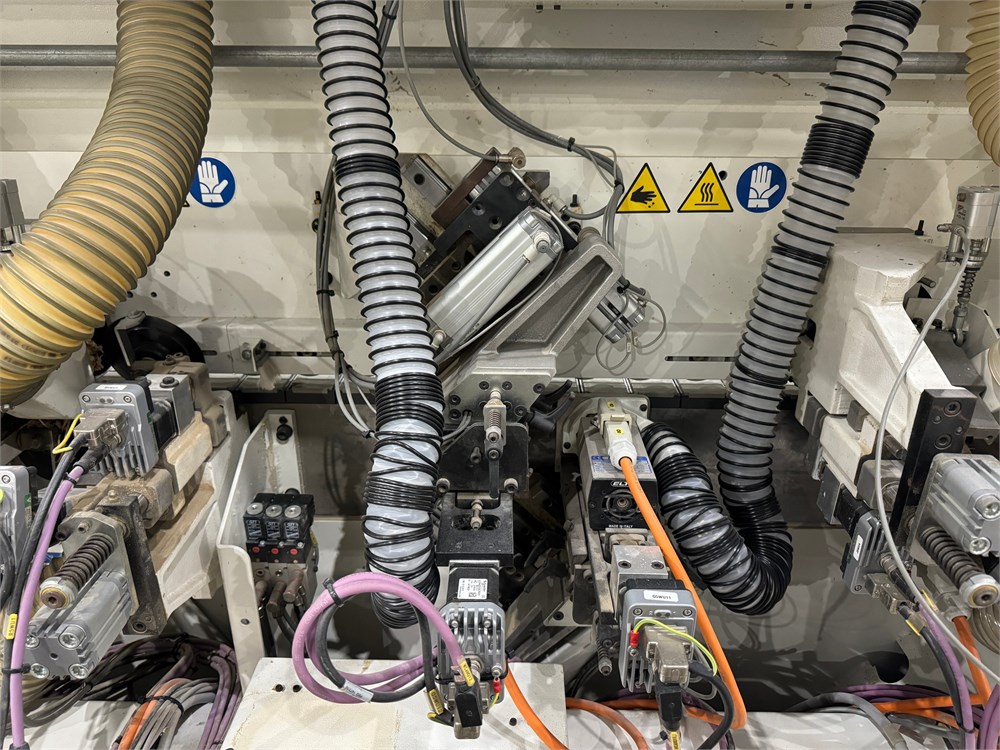

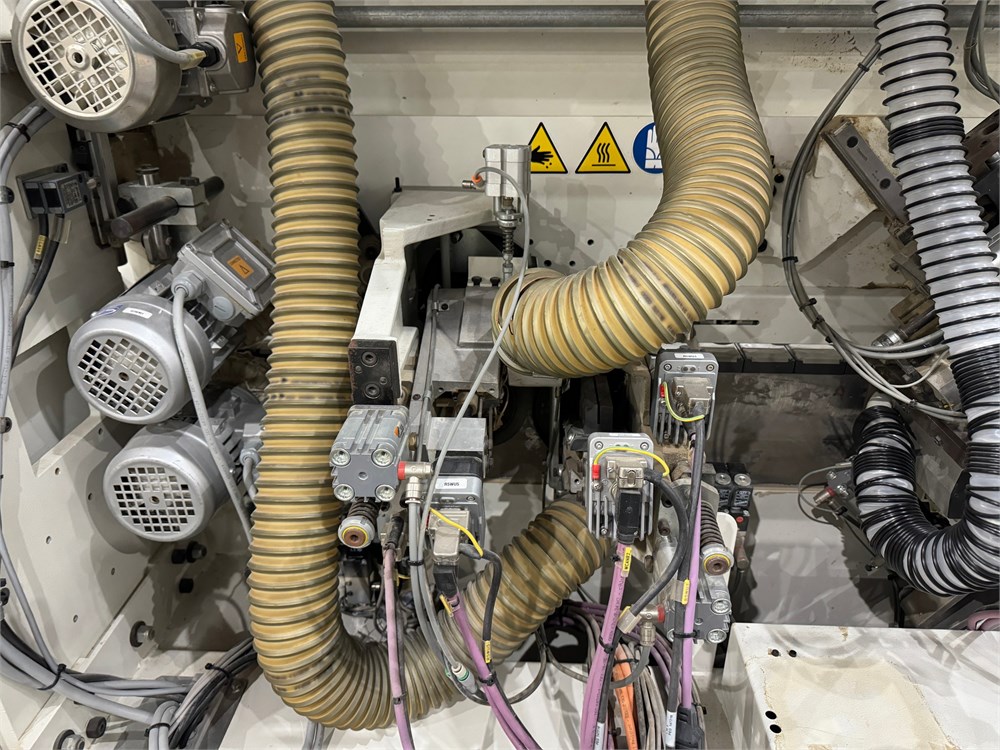

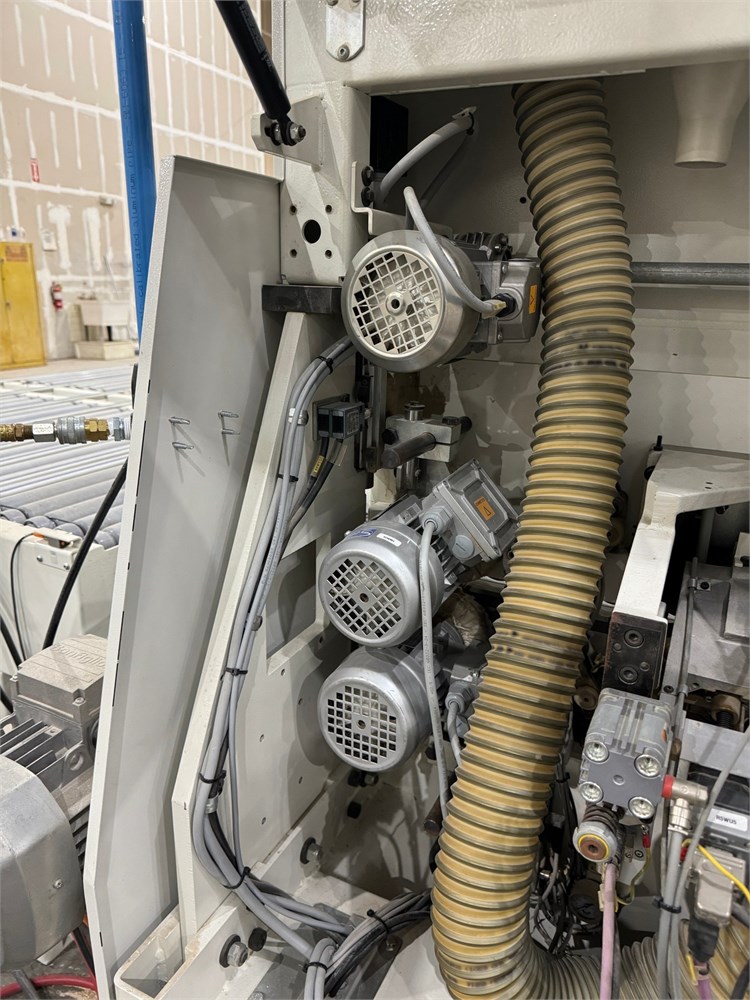

Pre-milling station:(2) 2.0 HP (1.5 kW) motors, to rectify/clean panels already sized.

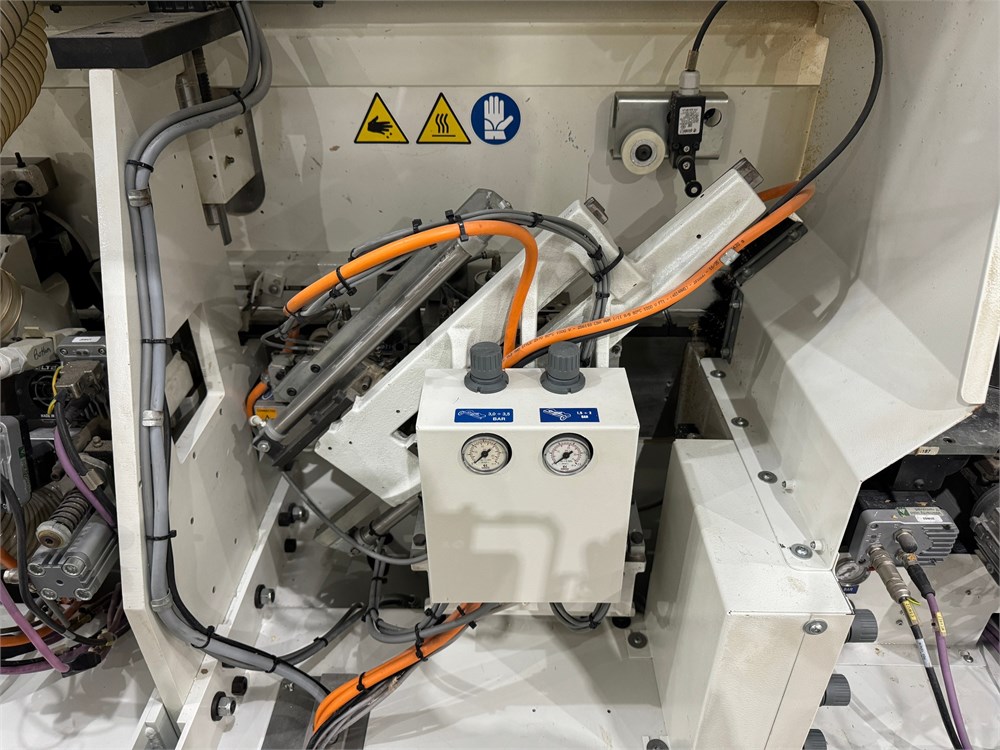

Adjustable In-feed Fence: Manually pre-set with digital indicator, pneumatic in/out positioning.

Automatic Strip & Coil Feed Magazine: For straight edges and 3 mm guillotine for coils.

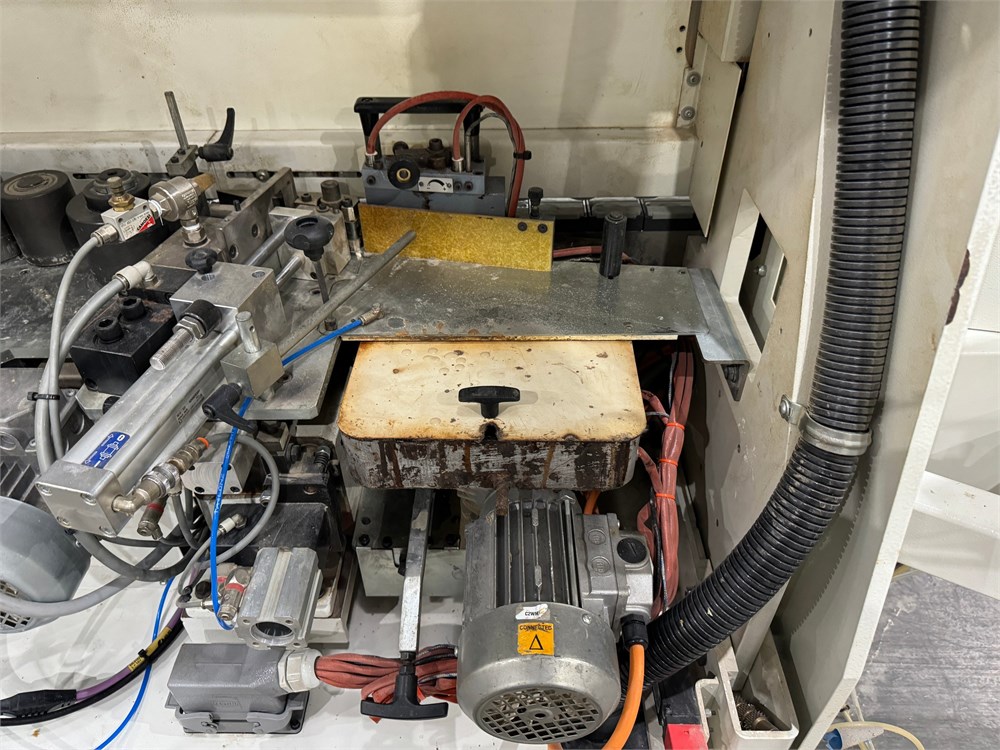

Gluing Station: For EVA (Hot Melt) with Quick change/disconnect Teflon glue pot for fastglue tanks changeif needed.Heat-up time approx. 10 Min.

Pressure Section: Manual digital positioning;Teflon coated pneumatic driven roller & (3) spring loaded idle rollers.

End Trimming Station:Front & rear 2 x 0.5 HP, 12,000RPMmotorsmounted on THK guides, swivels 0° - 15° for straight & angle cutting.

Top & Bottom Trimming Unit: 2 x0.7 HP - 12.000 RPM motors, capable of tilting & Servo driven

Corner Rounding Unit "Round 2M": corner rounding unit with (2) 0.80 HP independent motors that slide on THK guides, Servo driven.

Top & Bottom Profile Scraping Unit:with digital indicators. Large dia. copy wheels for max. accuracy, servo driven

Buffing Unit: Top/bottom, 2 x 0.25 HP - 2,800 RPM motors, tilting up to 12°.

"STARTOUCH" Controller with 12" touchscreen display, capable of storing (100) programs.

2-Speedfeed-speed of 40 & 60 FPM (12 & 18 MPM); 1 x 2.5 HP feed drive motor

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available