Biesse "Jade 225" Edgebander (2021)  Active

Active

Pladac Industries - Salinas, CA

Salinas, CA

- Current Price : $5,650.00 USD ( ) No Reserve

- 6 Bid(s)

- High Bidder: s****b

Late Model Homag Machinery - Salinas, CA ( Active #64679706 )

Complete shop closure! Featuring 2022 Homag Sawteq B-200 Beam Saw, 2022 Homag Drillteq V-200 Vertical CNC Machining Center, 2022 Homag Cabteq S-250 Case Clamp, 2021 Biesse Jade 225 Edgebander, plus much more!

-

Item Location

Salinas, CA

-

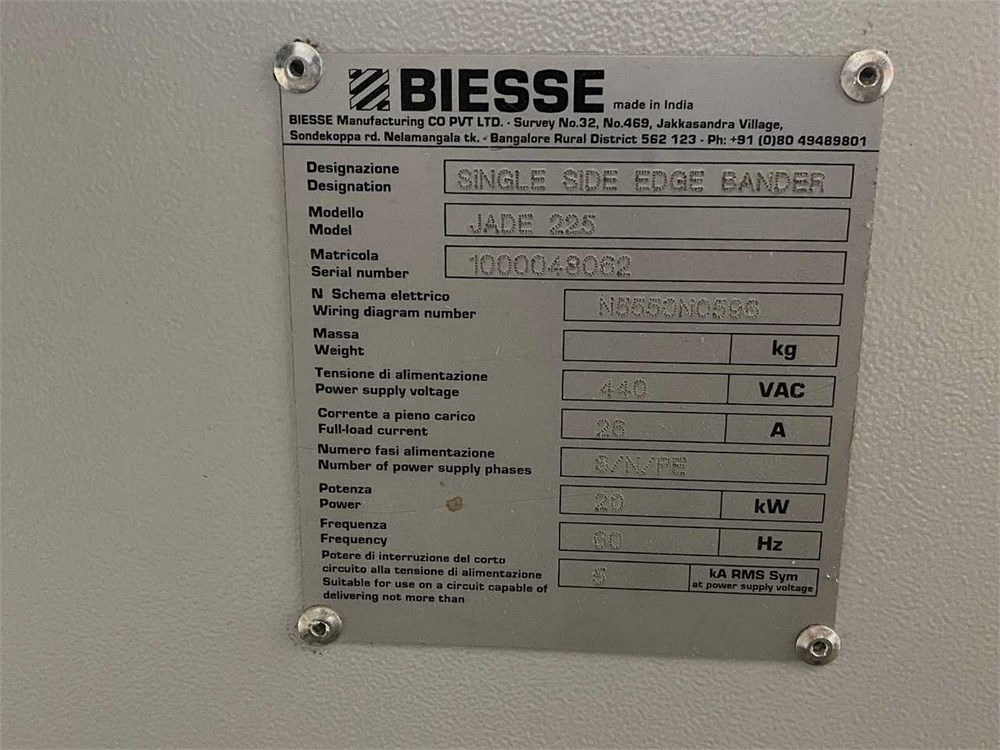

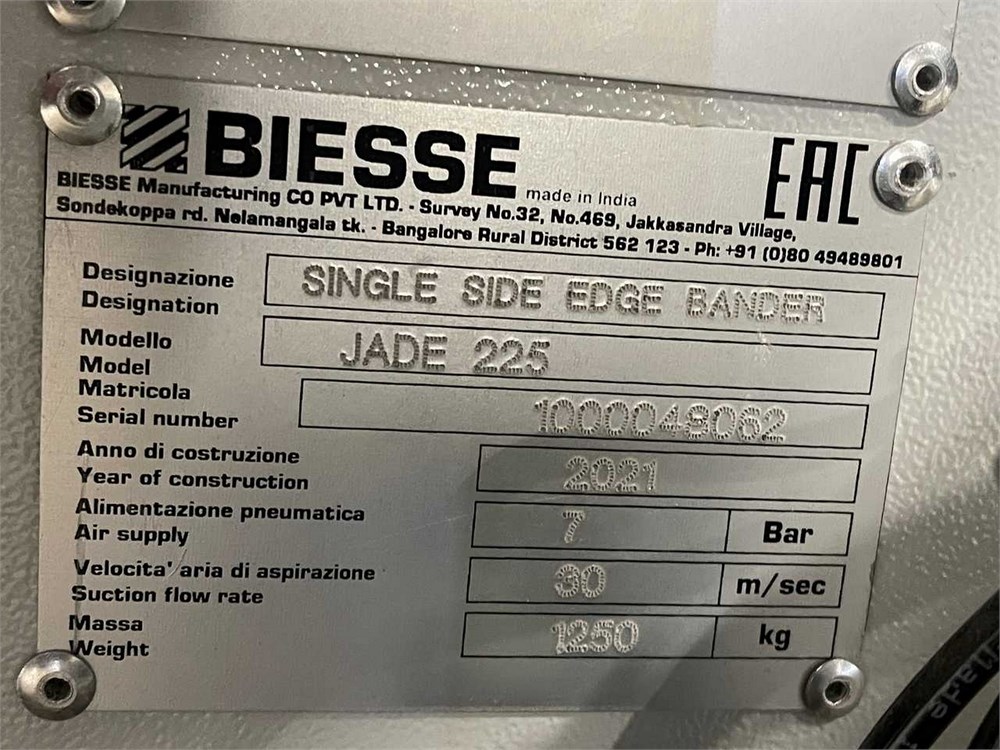

Make

Biesse

-

Model

Jade 225

-

Serial Number

1000048062

-

Year

2021

-

Phase

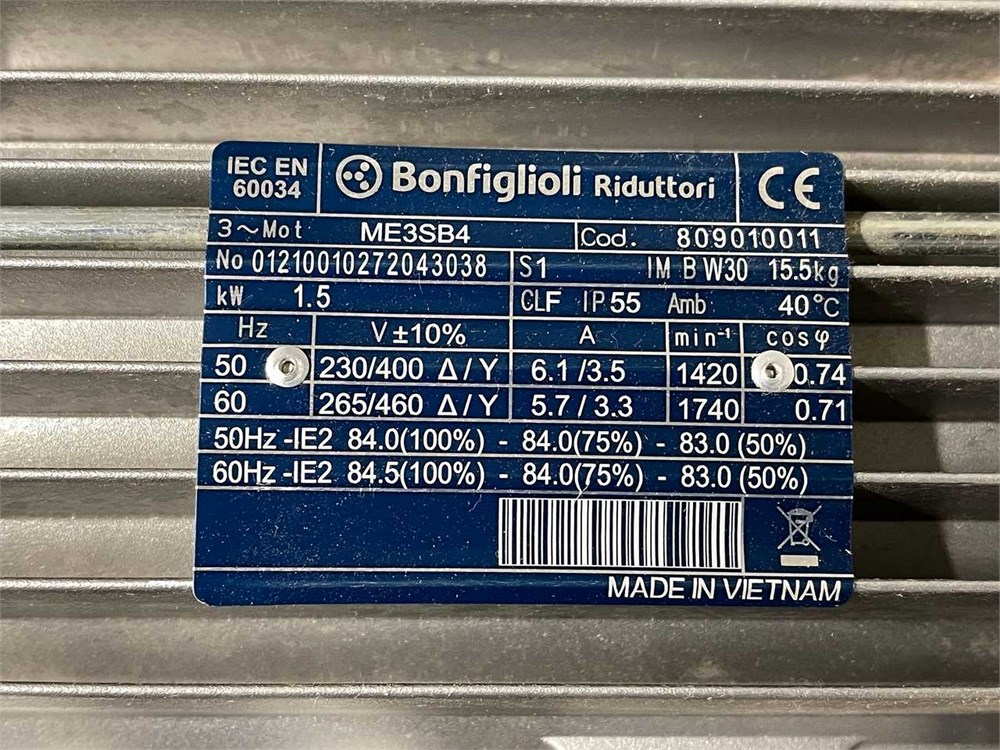

3 PHASE

-

Voltage

440 Volts

-

Inspection Date

See Homepage

-

Final Removal Date

See Homepage

-

Estimated Dimensions

168" L x 48" W x 66" H (machine), 24" L x 18" W x 24" H (transformer)

-

Estimated Weight

2,750 Pounds

-

Seller Comment

Pre-mill

-

Load Fee

A rigger is required. Buyer's Responsibility for Break-down, loading and removal.

-

Lot Notes

Please see video!

-

page views

688

Biesse "Jade 225" Edgebander (2021)

See video of machine in operation

Edge and Workpiece Capacity: Edgebanding thickness 0.4 -8 mm (0.01" - 0.31"), min. panel width 85 mm (3.5"),min. length 150 mm (5.9"), max. panel thickness 10 -60 mm (0.39 - 2.36").

Touch screen PLC, rotating control panel

Edgebanding infeed table, 32" diameter

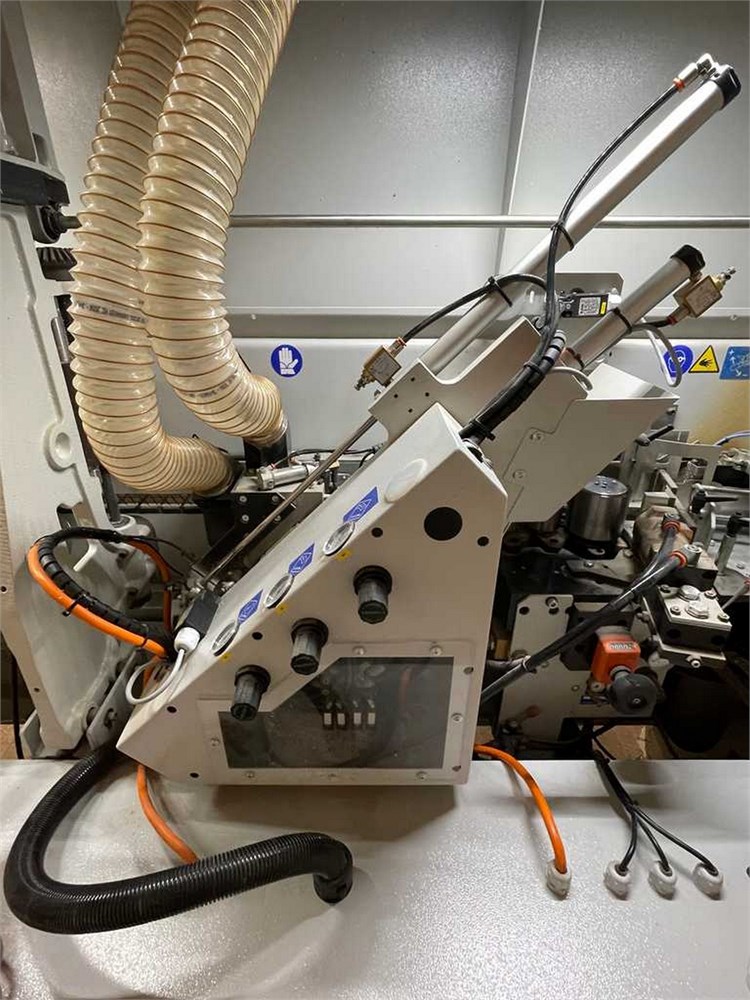

Automatic strip and coil feed magazine with "HD" shear type 3 mm PVC guillotine.

Infeed fence

Anti-Adhesive Unit: The unit applies an anti-adhesive liquid on the top and bottom surface of the panel.It is positioned before the pre-milling unit. The anti-adhesive liquid is applied with precision by means of injectors controlled by the machine control.

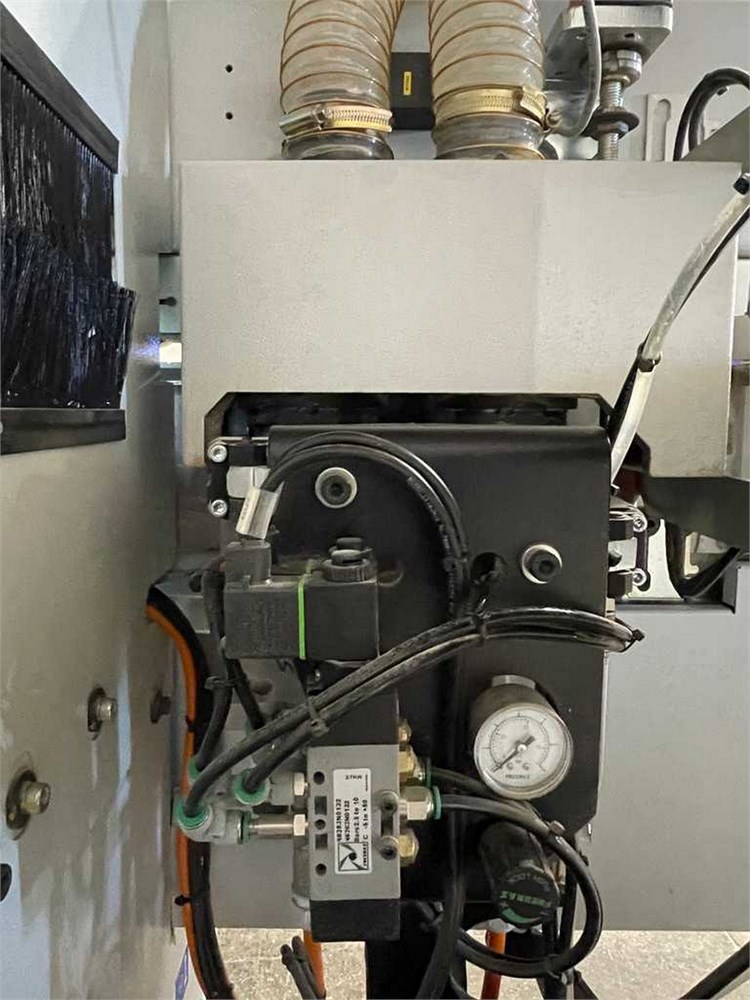

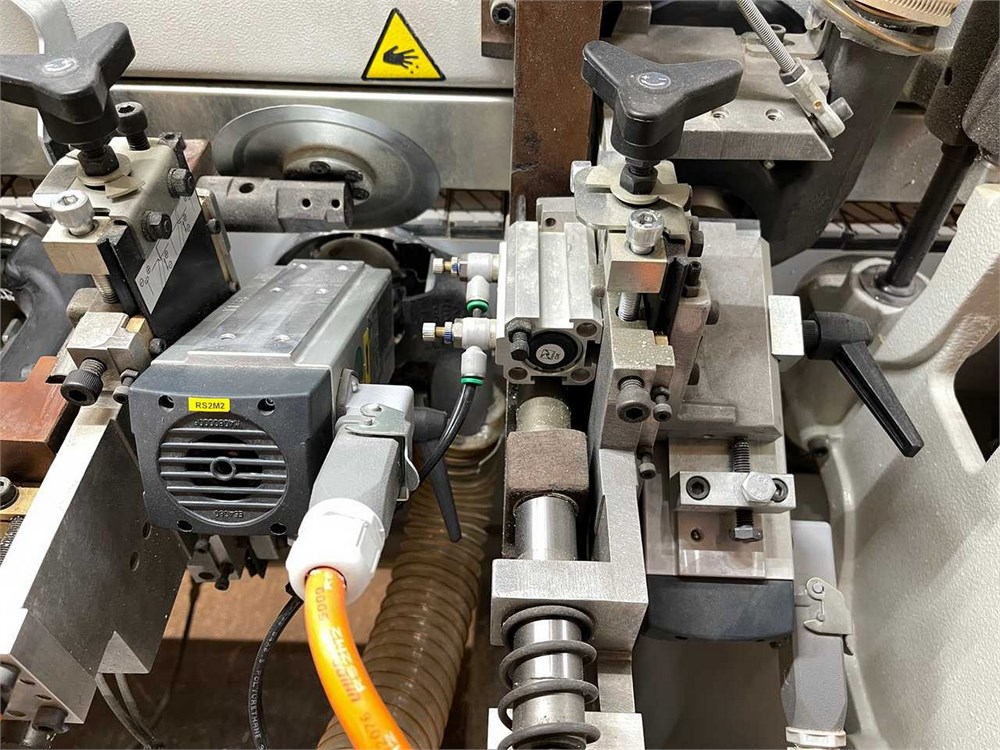

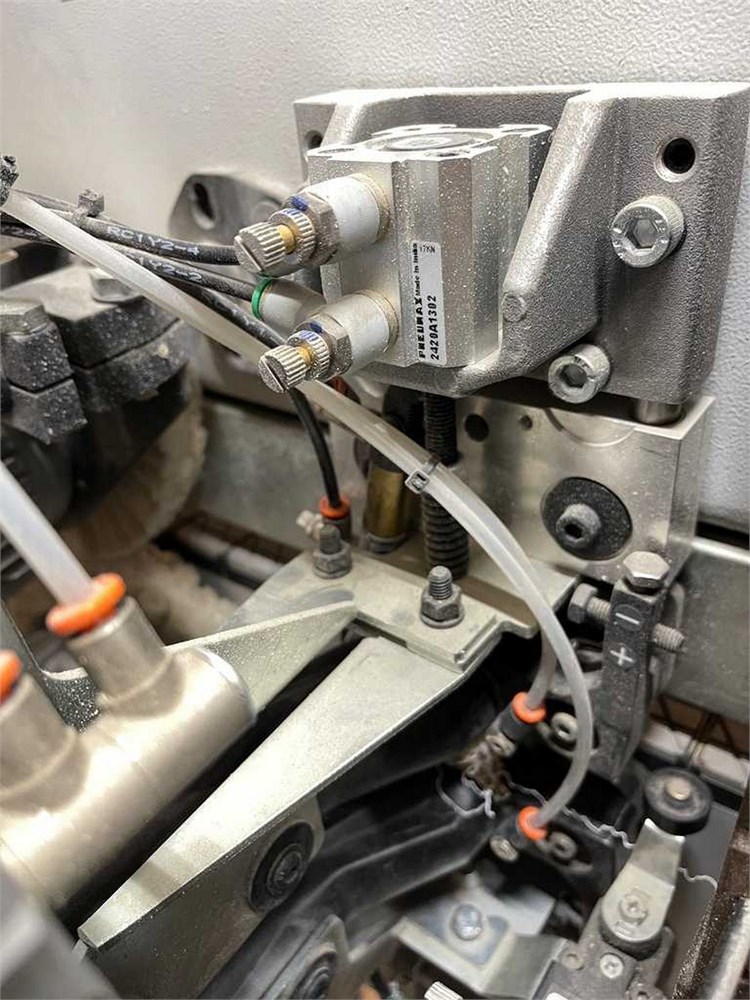

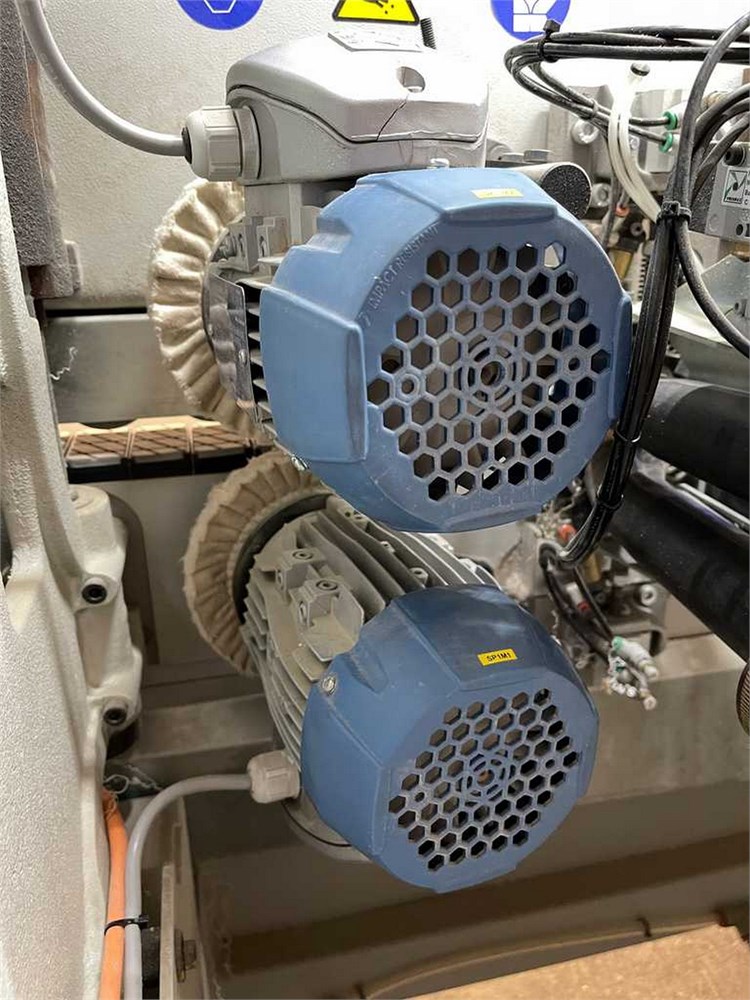

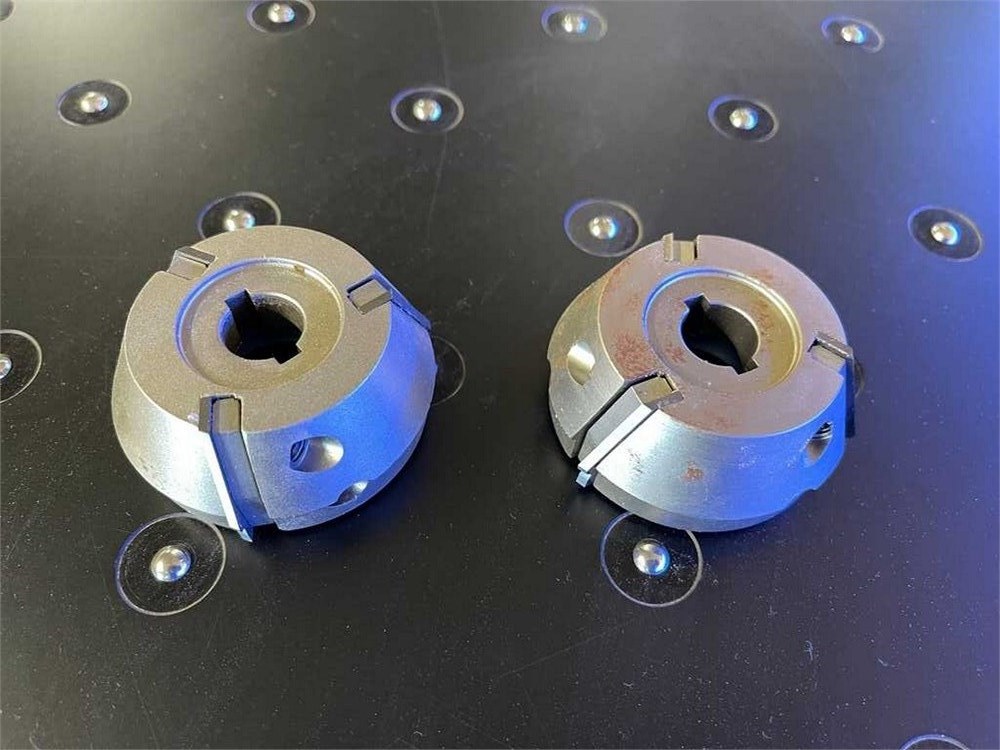

Pre-Milling Unit: (2) 2.4 HP motors operating at 12,000 RPM;"AUTO-SET" device ensures optimum positioning of the cutters according to the thickness of the panel being machined; numerical readouts, pneumatic exclusion when not needed.

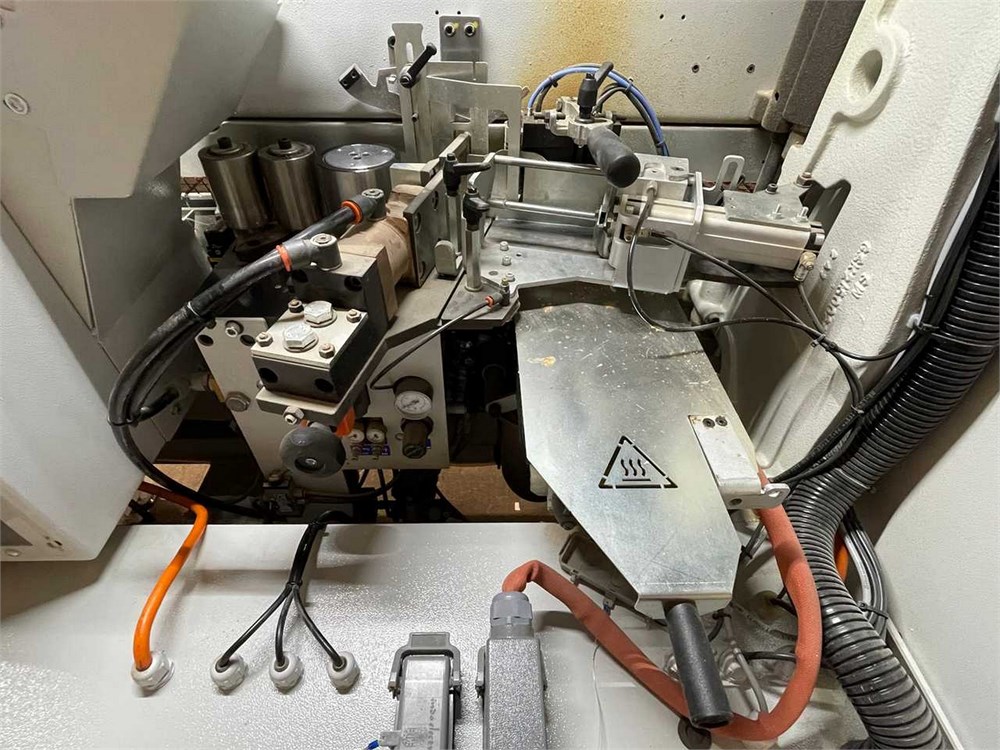

Glue Unit: Teflon coated Hot Melt glue pot, digital thermostats with automatic kick down when machine is in idle mode.4.4 pounds capacity; "QMS" (quick melt - approx. 10 - 12 minute heat up time)

Pressure Section: (1) Large dia. "non-stick" coated drive roller and two (2) chrome plated pneumatic inclined pressure controlled idle rollers; horizontal adjustment w/ digital indicator.

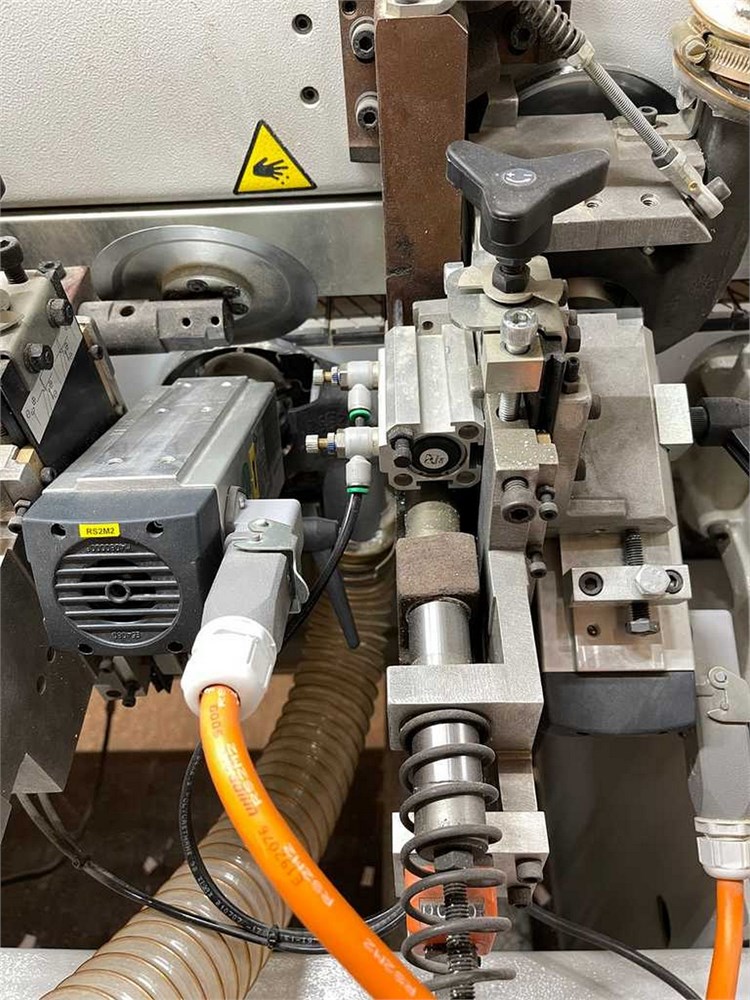

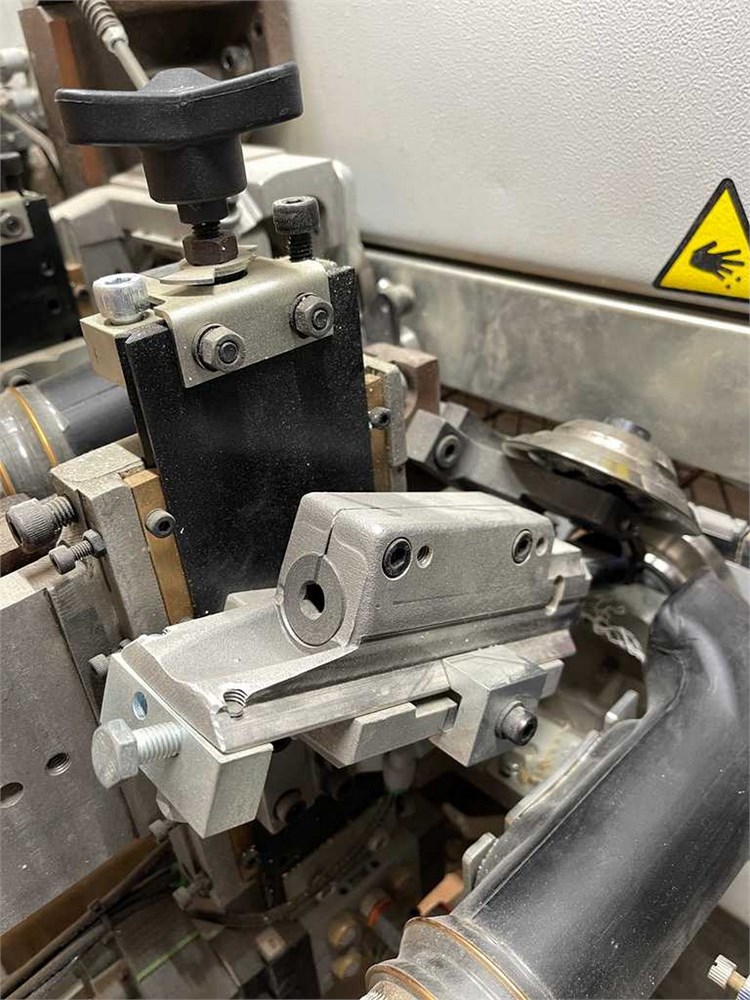

End Trimming Unit: Front & rear end trim motors, 1.0 HP,12,000 RPM, motors travel on 45° slides and pneumatic tilt 0° - 15° form the control panel.

Top/bottom Trimming Unit: Top and bottom flush or bevel trims with "Quick Change" motors 0.8 HP, 12,000 RPM, digital readouts for easy setup.

Top/bottom Profile Scraping Unit: Finishing unit to eliminate previous machining imperfections; pneumatic exclusion from the machine control; external collection box.

Top/bottom Flat Scraping Unit: Top and bottom scrapers for 3 mm thick PVC banding.

Top/bottom Buffing Station: 0.5 HP, 2,800 RPM, units tilt 0° - 30°.

Top pressure beam & motorized feed track with "anti-slip" "Quick Change" snap on 80 mm wide x 60 mm long rubber pads, low friction nylon-graphite self-lubrication chain pads.

Lighted Sound Enclosure and Outboard Panel Support, over all trimming stations, industrial lights and viewing windows,extendible side panel support rail.

Fixed Feed Speed,39 FPM, 2 HP feed drive

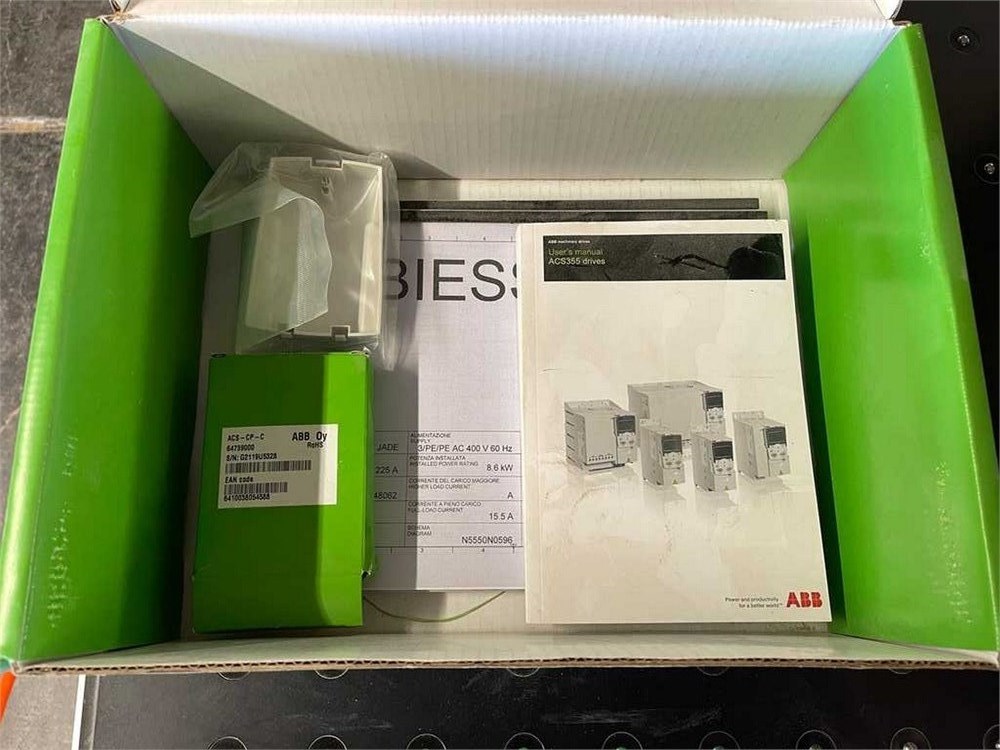

External electrical transformer

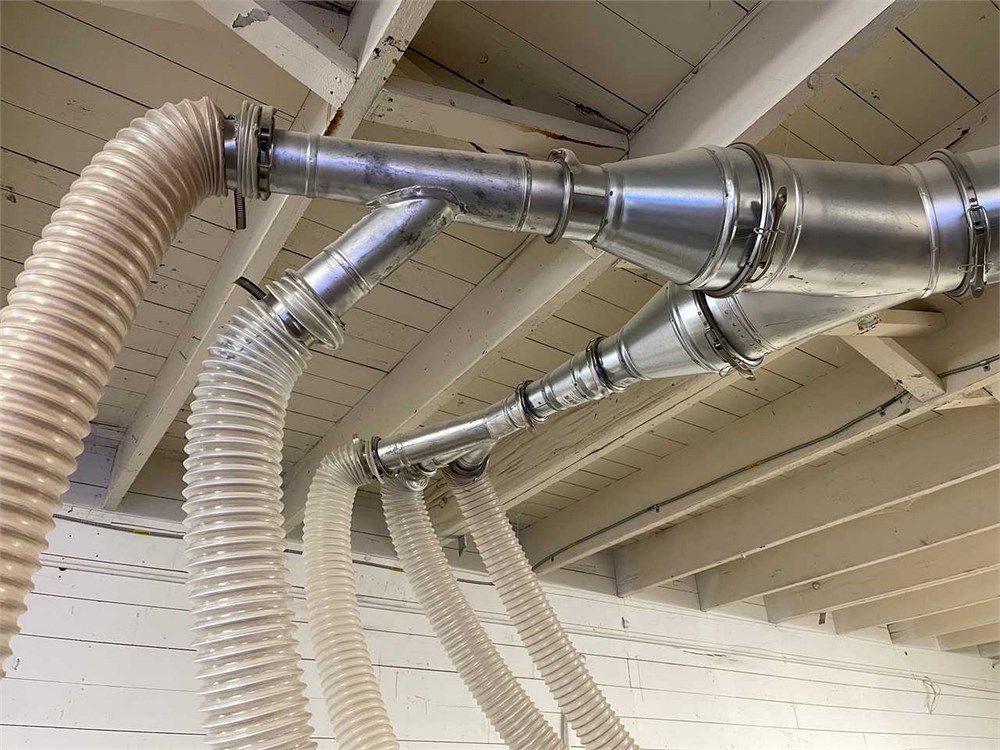

Dust manifold and flex hose (to first joint joining main trunk, other dust pipe and flex hose offered in different lots)

Tool kit

Installed and extra tooling

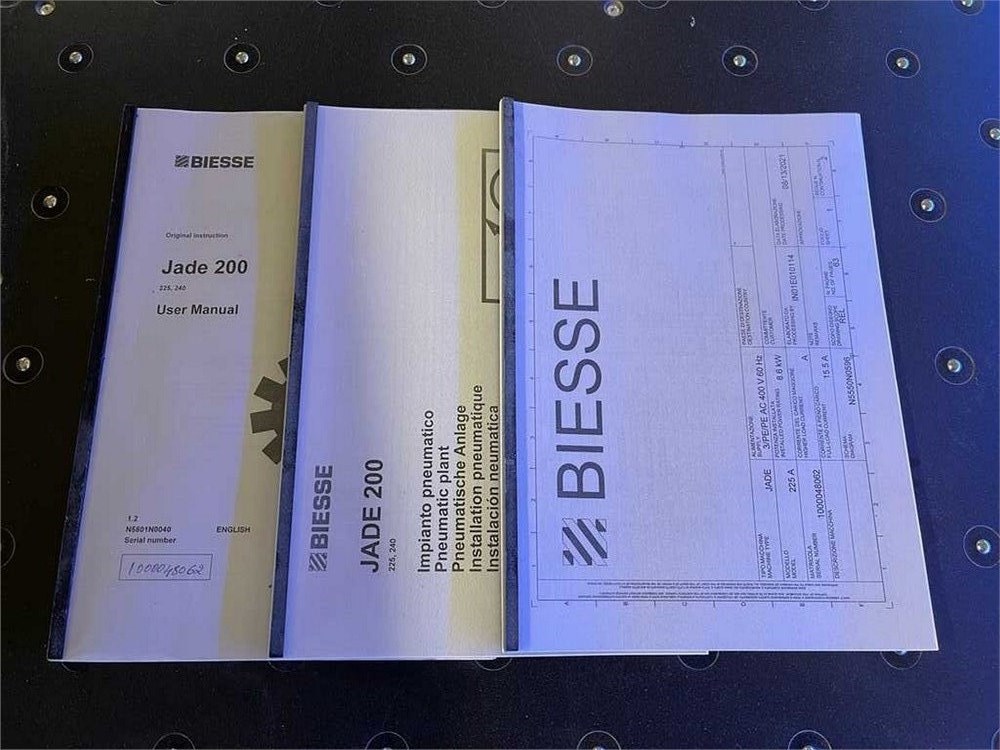

Manuals

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense). MachineryMax does not ship- All buyers responsible for their own freight - For freight quotes please contact your preferred broker, or contact Aaron, at Always Trucking 541-608-6532

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration