LOT# 007 HOMAG OPTIMAT KL73/A3 EDGEBANDER - SEE VIDEO  Ended

Ended

ACCUCUTT INC 624 MILLWAY AVE CONCORD ON, CANADA L4K 3V3

- Winning Bid : $1,000.00 CAD Sold

- 6 Bid(s)

- High Bidder: D****0

ACCUCUTT INC * BIESSE SKIPPER, MASTERWOOD CNC - 180 LOTS IN CONCORD, ON CANADA ( Closed #16744517 )

FEATURED LOTS: BIESSE SKIPPER 100 AUTO FEED BORING MACHINE yr 2004 * MASTERWOOD CNC MACHINING CENTER * TOS SVITAVY FWP22 MOULDER * INTERNATIONAL 40S 2 AXLE BOX TRUCK * ACCUSYSTEMS HPP AUTOMATIC DRILL AND DOWEL MACHINE * HOLZMA HPL11 AUTOMATIC BEAM SAW * HOMAG KL73/A3 EDGEBANDER * HYSTER 6000 LB CAPACITY FORKLIFT * KNAPPE TOE KICK SAW * SILVER SAW16P WIDEBELT SANDER * POLYMAC SINGLE 89 CONTOUR EDGEBANDER & SPEEDY 90 TRIMMER * J&P HORIZONTAL DRILL * BREVETTI PRISM MAXI SAW * WEMHONER CASE CLAMP * BLUM & GRASS HINGE BORERS * 24" BANDSAW * DOUCETTE SDM2 CLAMP * CRAFTEX 2 BAG DUSTCOLLECTOR * PENTALIFT 6000LB CAPACITY SCISSOR LIFT * DOUCETTE LINEAR & TRANSFER CONVEYORS * BECKER VACUUM PUMP * CANTILEVER RACKING....SHEET GOODS....AND MUCH MORE.

SELCO & HOLZMA BEAM SAW BLADES: OVER 80 SAW BLADES (NEW OR RECENTLY SHARPENED)

-

Item Location

624 MILLWAY AVE CONCORD, ON CANADA L4K 3V3

-

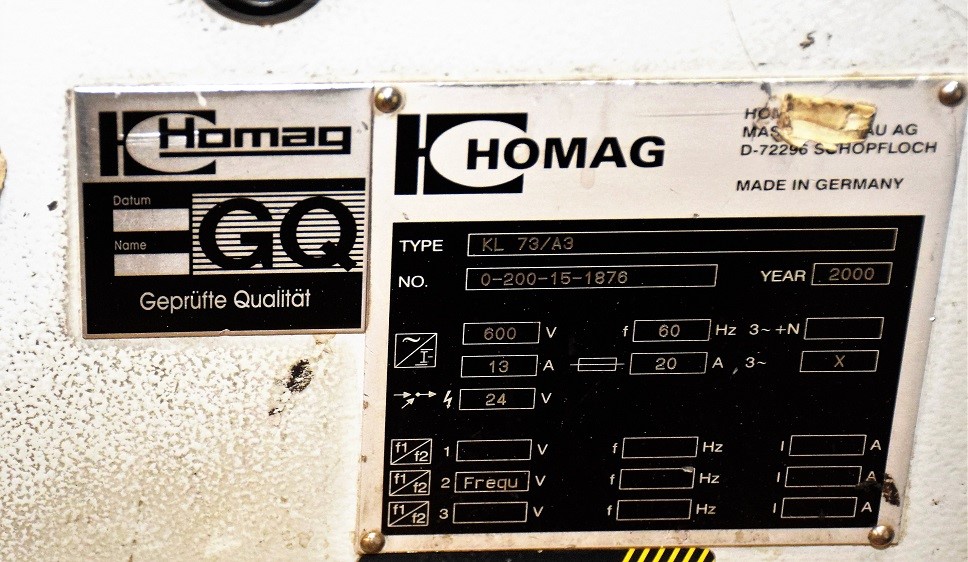

Make

HOMAG

-

Model

KL 73/A3

-

Serial Number

200-15-1876

-

Year

2000

-

Phase

3 PHASE

-

Voltage

600VOLT

-

Inspection Date

BY APPOINTMENT CALL ROBERT AT 416-904-2475

-

Final Removal Date

JULY 05, 2019

-

Estimated Dimensions

13'L X 4'W X 7'H

-

Estimated Weight

5,500 LBS

-

Seller Comment

SEE SHIPPING DETAILS

-

page views

1499

Homag Model KL73/A3 EDGEBANDER

THIS MACHINE IS CURRENTLY IN PRODUCTION AND CAN BE INSPECTED BY APPOINTMENT. COMES WITH MANUALS.

- Left to right machine design

- Edgebanding thickness capacity 0.4 mm to 3 mm

- Coil or strip feed

- Work piece thickness capacity 12 mm to 60 mm (0.47" to 2.36")

- Work piece overhang 30 mm (1.18")

- 3" wide rubber padded table feed chain

- Powered adjustable upper pressure beam with rubber hold down belt

- Outboard roller top adjustable panel support beam

- 20" infeed load space

- 1st station: edgebanding application and hot glue, 24" diameter single edgebanding coil tray

- Top mounted quick melt hot glue system

- Bottom teflon lined glue pot

- System accepts pellet type glue

- Reversible rotation of glue roller

- Pneumatic 3mm pvc edgebanding guillotine

- (1) 5-3/4" diameter x 2-3/4" high main pressure roller, (2) 2-3/4" diameter x 2-3/4" high aux pressure rollers

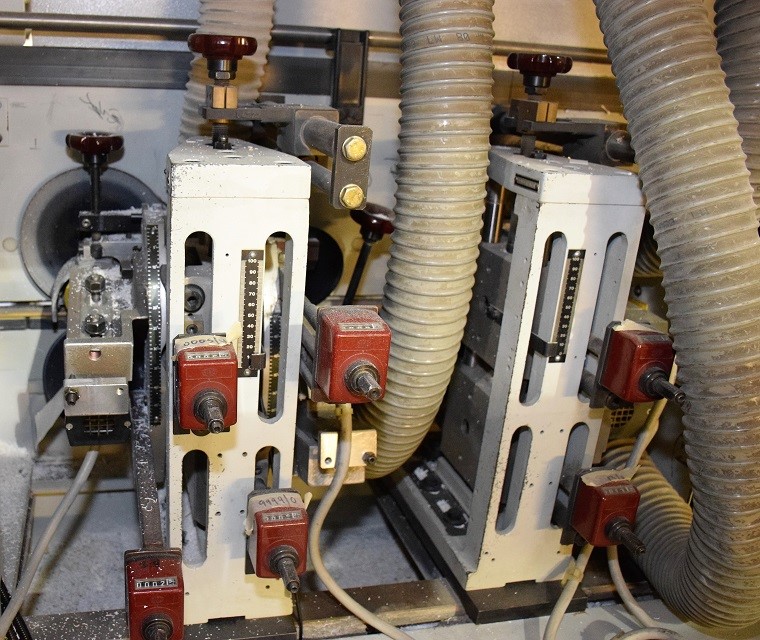

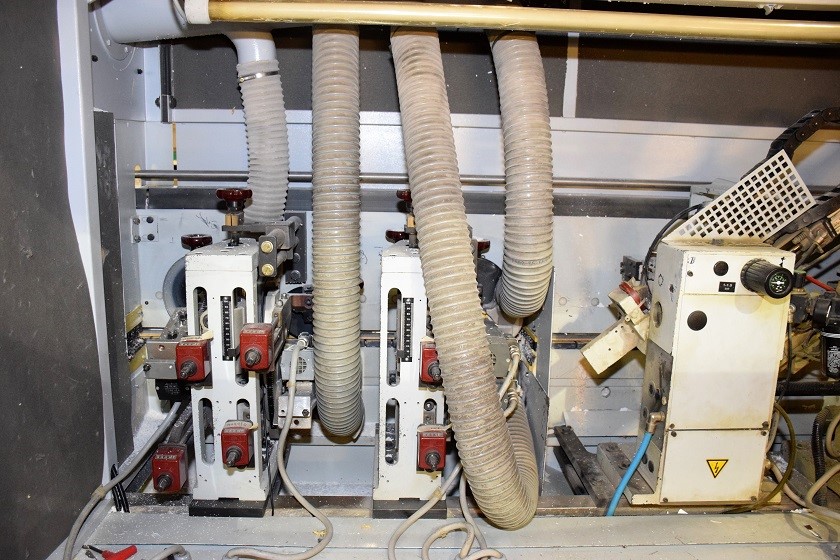

- 2nd station: front and rear edgebanding trimmers, 0.81 kw trimmers, 12,000 rpm

- Chamfer/straight cut off positions

- 3rd station: top and bottom rough trimmers, 1.5 kw trimmers, 12,000 rpm

- 4th station: top and bottom tilting fine trimmers,0.4 kw trimmers, 12,000 rpm, 0 to 30 degree trimmer head tilt range

- Mechanical digital readouts for 3rd & 4th stations

- Sound and safety enclosure around 2nd thru 4th stations

- Front lift up hoods with inspection windows

- 5th station: open

- 6th station: top and bottom edge buffing heads 0.25 kw, 3600 rpm; 2.2 kw feedworks drive with variable speed thru gear box design

- Homatic NC-21 control panel

- LCD display with soft touch keypad

- PLC program storage

- Dual electronic temperature controls

- Ligmatech Optimat ZHR-01 Boomerang Edge Bander Automatic Return Conveyor (2007)

- Model Optimat ZHR-01/L/055 Year 2007 460 volt three phase, 60 hz, 16 amps

- Panel specifications: Panel length capacity 300 mm to 2500 mm (11-3/4" to 98-3/8")

- Panel width capacity 50 mm to 1450 mm (2" to 57")

- Panel thickness capacity 8 mm to 60 mm (5/16" to 2-3/8")

- Working speed: min 8 m/min (26 ft/min) to 40 m/min (131 ft/min)

- Largest motor 0.75 kw

- (3) 3/4" wide rubber belted adjustable infeed conveyor belts

- 43" wide x 82" long infeed powered roller conveyor table area

- 42" long rubber covered table rollers

- Line shaft and flat rubber belt type roller drive system

- Bottom adjustable table legs with a passline adjustment range of 31" to 40"

- (5) automatic cross transfer arms lift parts from infeed to out feed table

- Arms are controlled by electric eye scanner at infeed of machine

- 43" wide x 82" long outfeed powered roller conveyor table area

- 42" long rubber covered table rollers

- (1) 36" wide x 144" long powered rubber belted return conveyor table

- 31-1/2" wide rubber conveyor belt (1) 36" wide x 80" long gravity roller end table

- 34-1/2" long PVC covered table rollers, 2-1/2" dia on 3" centers

- Side infeed mounted machine control panel

* Edge Thickness: 0.3 – 3 mm

* Min. Panel Width: 55 mm

* Max. Panel Thickness: 55 mm

* Feed Speed Variable: 18 – 24 MPM (59-78 FPM)

* End Trimming Unit HL 81 # 3047: (2) 0.25 HP, 200 Hz, 12,000 RPM Trim Motors

* Bevel / Fine Trimming Unit: Top & Bottom each 0.5 HP, 12,000 RPM

* Buffing Unit # 4402: Oscillating Top & Bottom 0.25 kW,

600 VOLT, 3 PHASE

ELECTRICAL DISCONNECT FEE...$ 50.00

RIG & LOAD FEE...$ 100.00

US CUSTOMS BROKER..."NEAR NORTH" (716) 204-4020

US BUYERS SHIPPING QUOTES:

ALWAYS TRUCKING...AARON (541) 608-6532

SHIPPING WITHIN CANADA QUOTES;

MANITOULIN TRANSPORT (800) 268-9994

OVERSEAS CONTAINER QUOTES:

LISA JONES (416) 896-2688

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginUS CUSTOMS BROKER..."NEAR NORTH" (716) 204-4020

US BUYERS SHIPPING QUOTES:

ALWAYS TRUCKING...AARON (541) 608-6532

SHIPPING WITHIN CANADA QUOTES;

MANITOULIN TRANSPORT (800) 268-9994

OVERSEAS CONTAINER QUOTES:

LISA JONES (416) 896-2688

No information available

ALL SALES ARE FINAL

* CDN FUNDS: THIS AUCTION IS BEING HELD IN CDN FUNDS

* PAYMENT: IS REQUIRED WITHIN 48 HRS OF AUCTION ENDING. PLEASE DO NOT MAKE ANY FORM OF PAYMENT UNTIL RECEIVING YOUR INVOICE

* PAYABLE METHOD: TO EQUIPMENT AUTHORIYTY BY WAY OF WIRE TRANSFER, ETRANSFER OR DIRECT DEPOSIT ONLY.

* REMOVAL: AT BUYERS EXPENSE.

* REMOVAL DEADLINE: JULY 05, 2019

* INSPECTION: BY APPOINTMENT CALL ROBERT (416) 904-2475

* AUCTION END DATE: WEDNESDAY, JUNE 27 2019 AT 1:00 PM (EDT)

* BUYER PREMIUM: 15% BUYER PREMIUM SURCHARGE WILL BE ADDED TO THIS LOT

* ONTARIO TAXES: PLEASE NOTE ALL BUYERS ARE REQUIRED TO PAY 13% HST TAX ON THESE LOTS...A LINK TO THE CANADIAN GOV'T WEBSITE TO RECEIVE A FULL REFUND WILL BE PROVIDED.

* AS IS WHERE IS: ALL MACHINERY & EQUIPMENT IS BEING SOLD AS IS WHERE IS WITH NO WARRANTY.