Morbidelli "Universal 3615" CNC Router with Automatic Load/Unload  Ended

Ended

Morbidelli "Universal 3615" CNC Router with Automatic Load/Unload - Tempe, AZ

- Winning Bid : $39,951.00 USD Sold

- 99 Bid(s)

- High Bidder: w****d

Morbidelli "Universal 3615" CNC Router with Automatic Load/Unload - Tempe, AZ ( Closed #26192965 )

Furniture manufacturer in Phoenix, AZ area has moved to a new facility and is auctioning its 2015 Morbidelli. Fully automatic load and unload system. Asset no longer required for continuing operations.

-

Item Location

2063 E. Cedar St. Tempe, AZ 85281

-

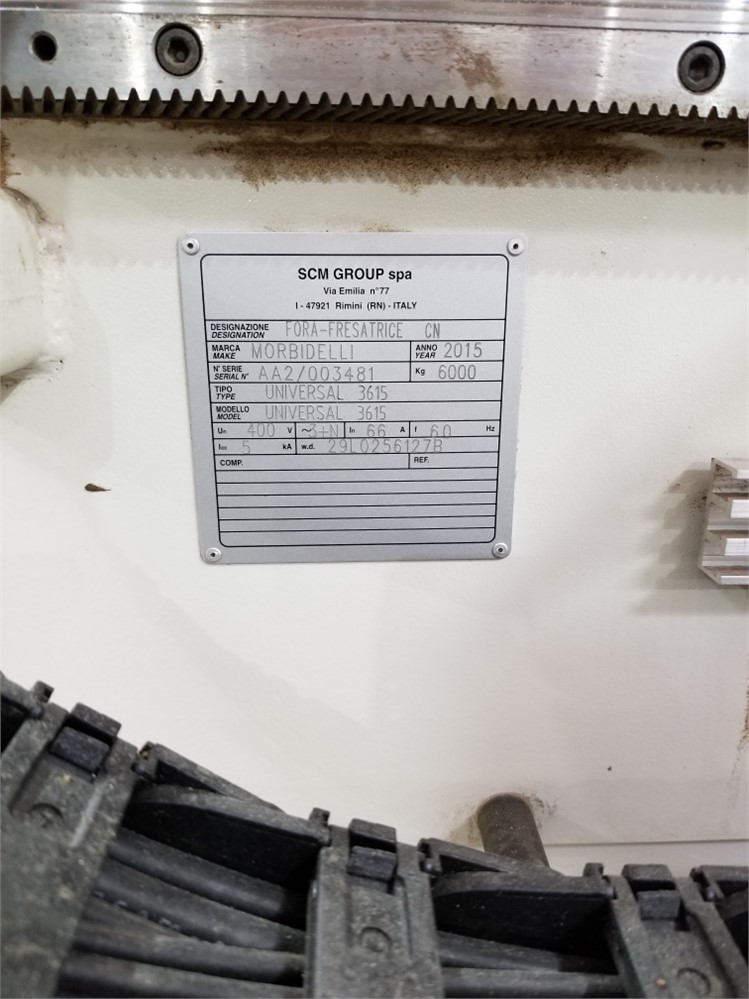

Make

Morbidelli

-

Model

Universal 3615

-

Serial Number

AA2/003481

-

Year

2015

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Inspection Date

By appointment only, contact Jack Ragan

-

Final Removal Date

February 16 - February 26, 2021 (by appointment)

-

Estimated Dimensions

568" L x 96" W x 106" H (overall cell as shown in photos)

-

Estimated Weight

15,000 Pounds

-

Seller Comment

This lot requires a rigger. Please contact Tom Estrate @ 602-377-4971 or [email protected] for quote and scheduling.

-

Load Fee

-

page views

11207

Morbidelli "Universal 3615" CNC Router with Automatic Load/Unload

See video of machine in operation

Automatic infeed

176" L x 80" W x 72" H overall dimensions

Scissor lift

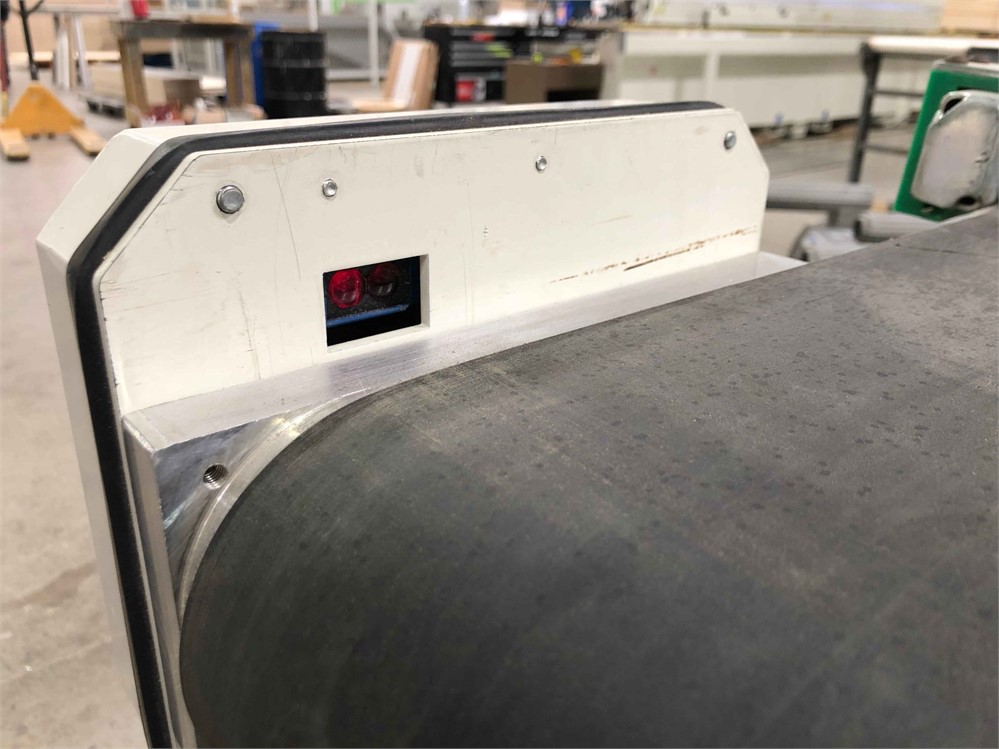

Photo eye at infeed onto machine

Three (3) side mounted vacuum cups and rollers

Control box for manual or automatic operation

Universal 3615 CNC

200" L x 96" W x 106" H overall dimensions

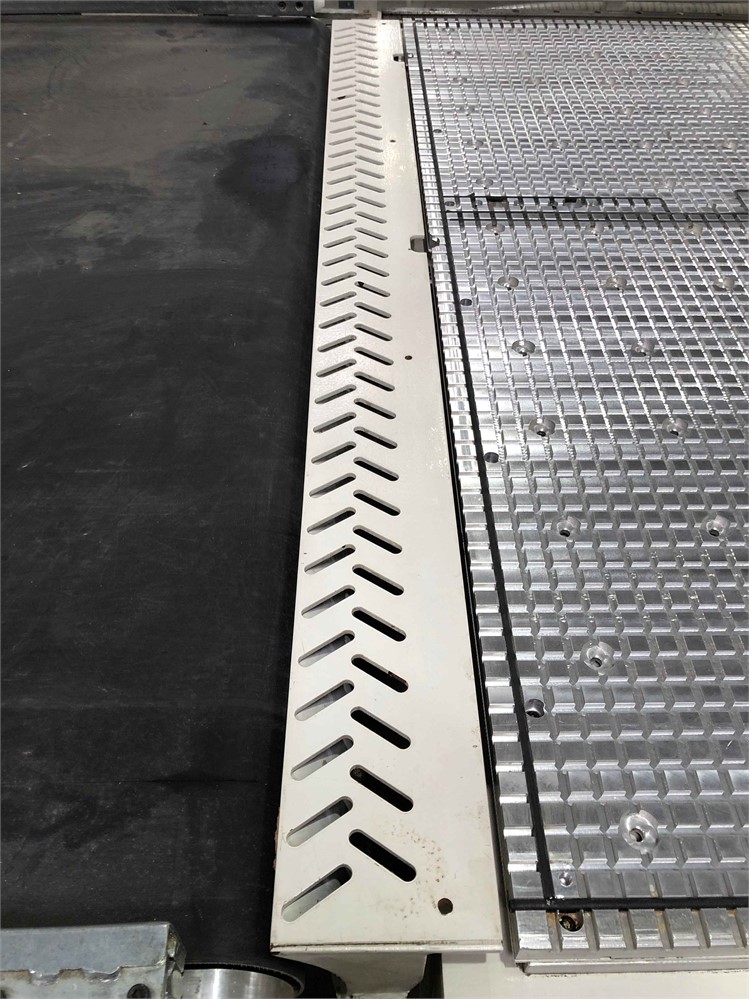

61" x 145" aluminum router table

Gridded for use of multiple vacuum zones

Pneumatic reference pins

Loading device with three (3) vacuum cups for loading panels onto machine

Automatic dust blast gates to clean table in advance of next panel

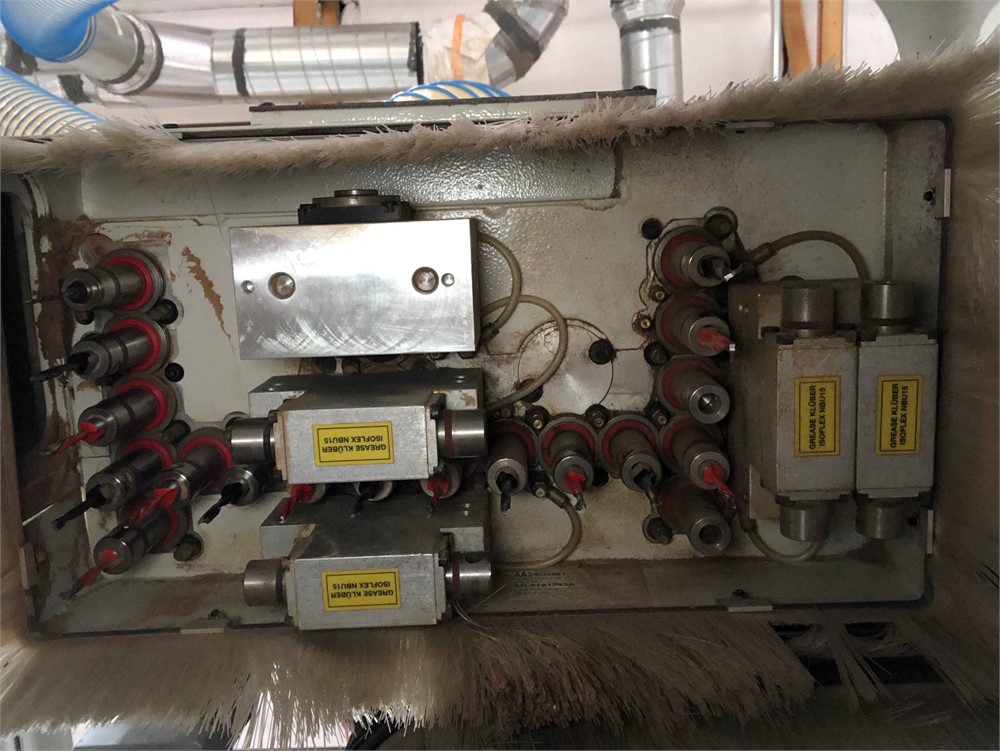

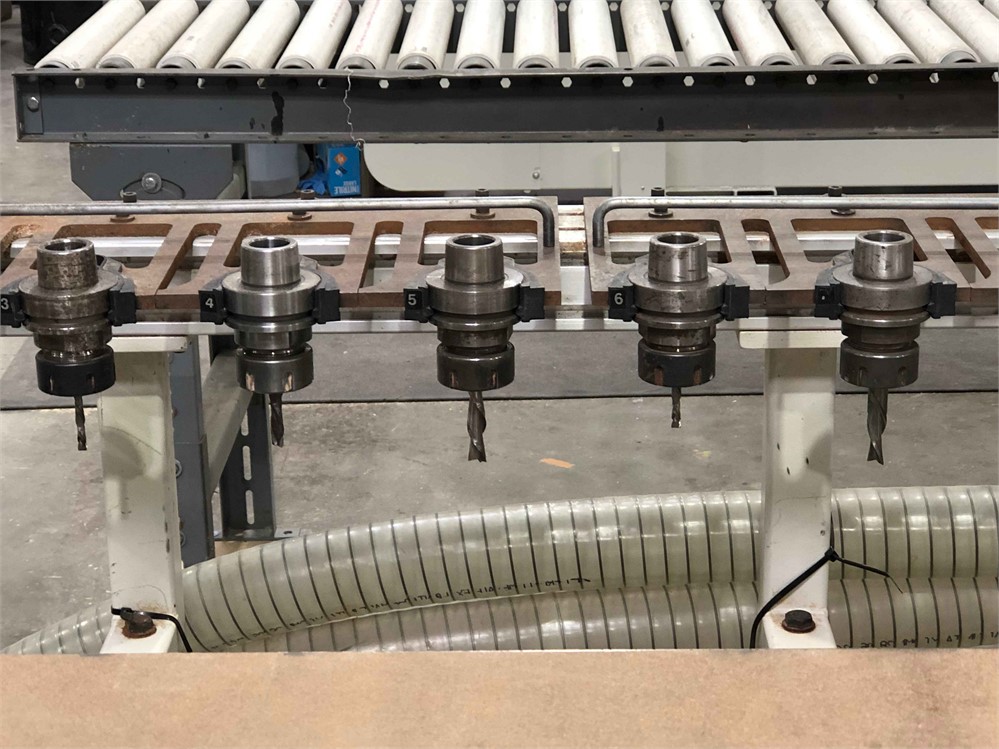

Drill unit

Eighteen (18) vertical spindles

Four (4) horizontal spindles (x axis)

Four (4) horizontal spindles (y axis)

X axis grooving saw

3 HP motor (typical for this model but NOT confirmed)

Router

12 HP (typical for this model but NOT confirmed)

Variable RPM

HSK, quick change

Air nozzle

Tool changer

20 position rack mounted on rear of machine

Sound enclosure

Automatic dust blast gates

Light barrier

Foot pedal control

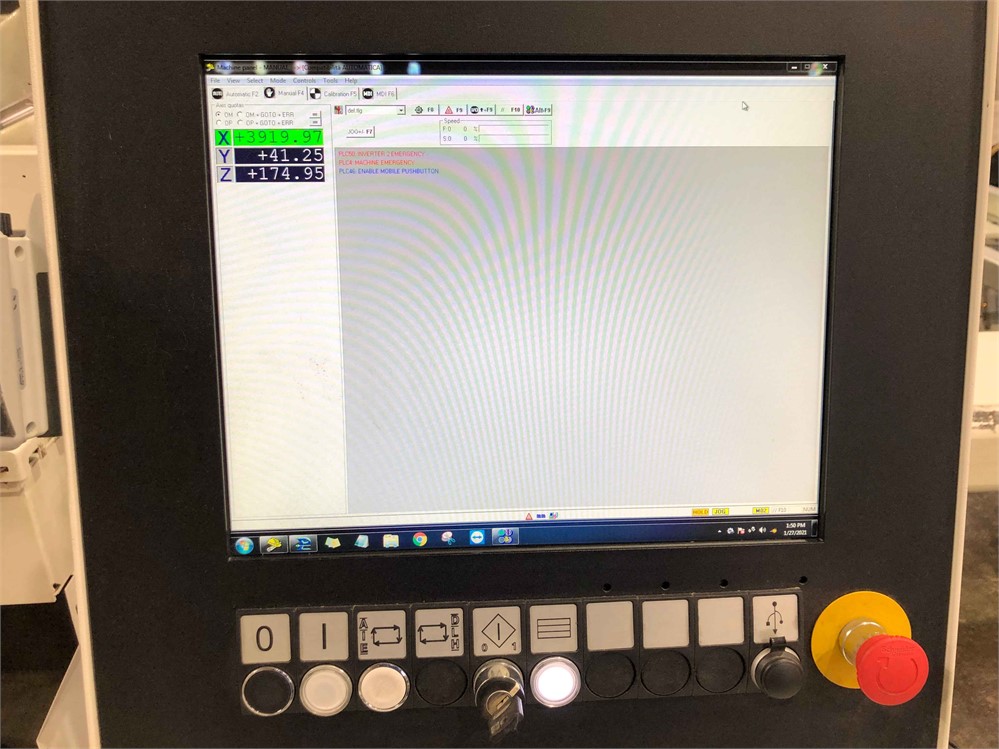

PC console mounted on mobile cart

XILOG software

PC operating in Windows

Flat screen, standard keyboard and mouse

Remote control pendant

Centralized lubrication

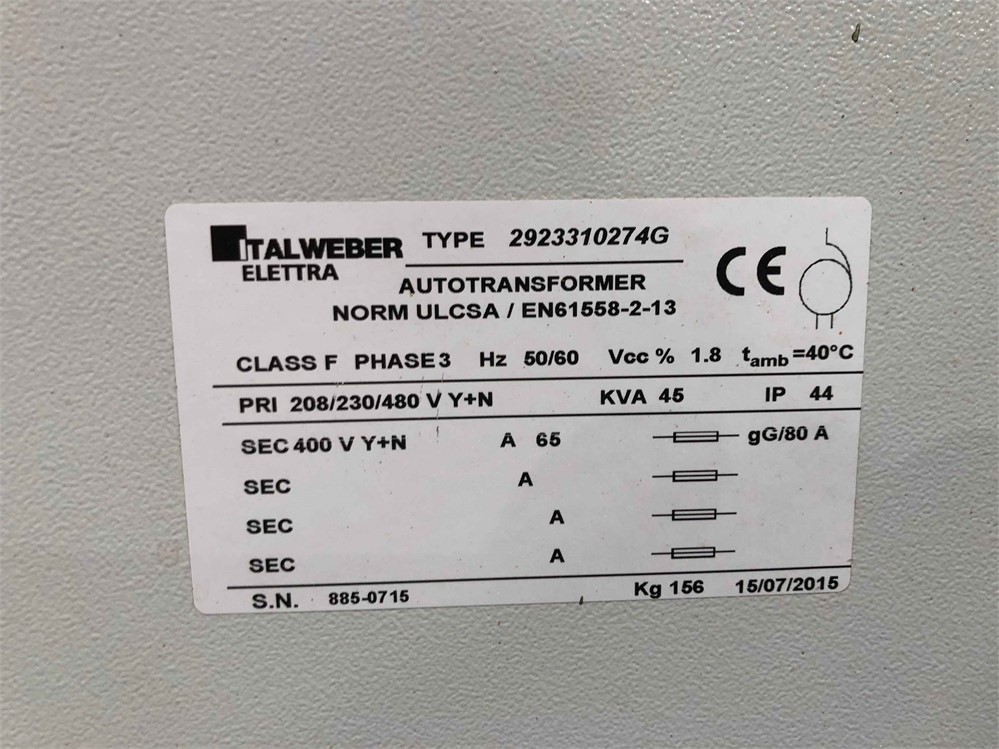

External electrical transformer

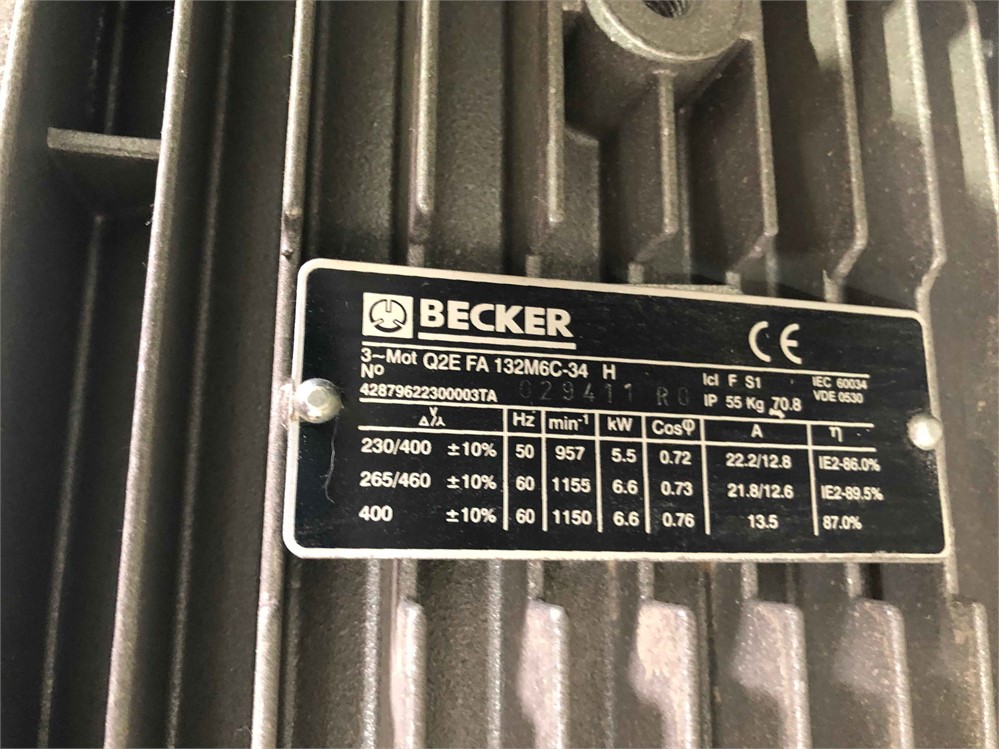

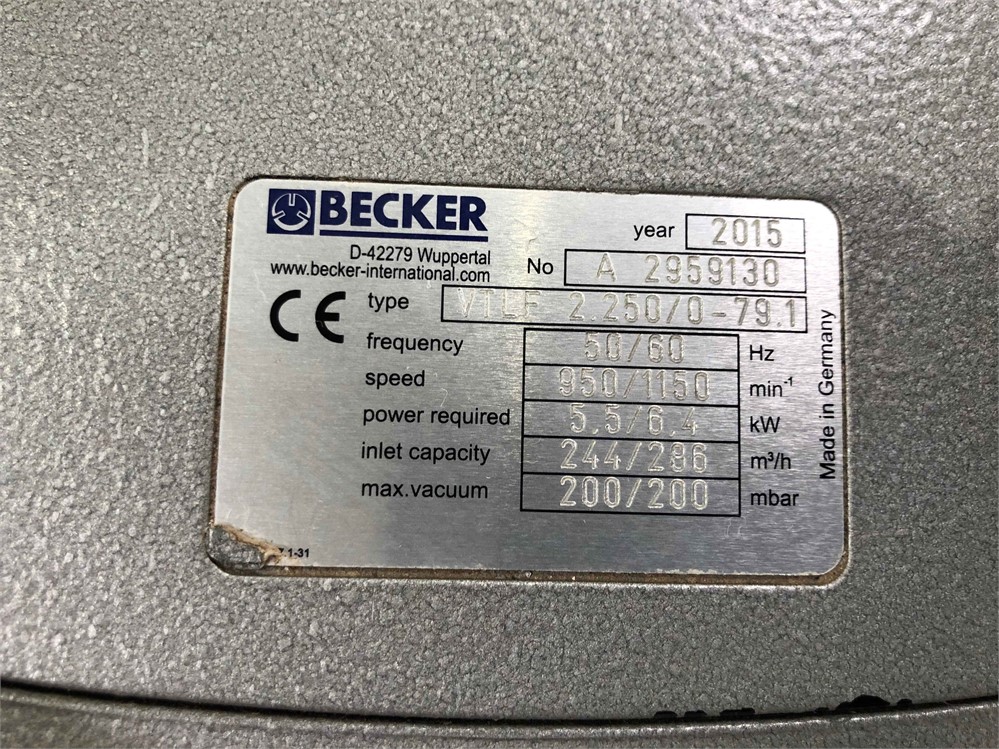

Two (2) Becker "VTLF-2.250/0-79.1" vacuum pumps

8.8 HP motors operating at 1,155 RPM

286 m/hr. inlet capacity (each)

Automatic outfeed

192" L x 65" W x 40" H overall dimensions

62" belt width

Photo eye at end of belt

Side fences

Control box for manual or automatic operation

Overhead dust collection with automatic blast gates

Dust plenum with bottom-mounted dust collection with automatic blast gate

Installed tool holders and tooling

3,053 hours as of 2/9/2021

Dust pipe and flex hose NOT included

Note from seller regarding full auto cycling, "After dropping the incoming sheet to reposition, the vacuum holds the sheet in place as repositioning happens. When the machine then advances again, sometimes the vacuum continues for enough time that the advancing sheet pulls the fly (spoil) board with it. A technician has told me that they think it is the three way valve that controls the vacuum distribution. It boils down to a timing issue in releasing the vacuum so the incoming sheet can advance to final positioning."

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.