Brandt "KDF-770" Edgebander  Ended

Ended

Brandt "KDF-770" Edgebander - Addision, IL

- Winning Bid : $3,200.00 USD Sold

- 23 Bid(s)

- High Bidder: W****S

Brandt "KDF-770" Edgebander - Addision, IL ( Closed #26116162 )

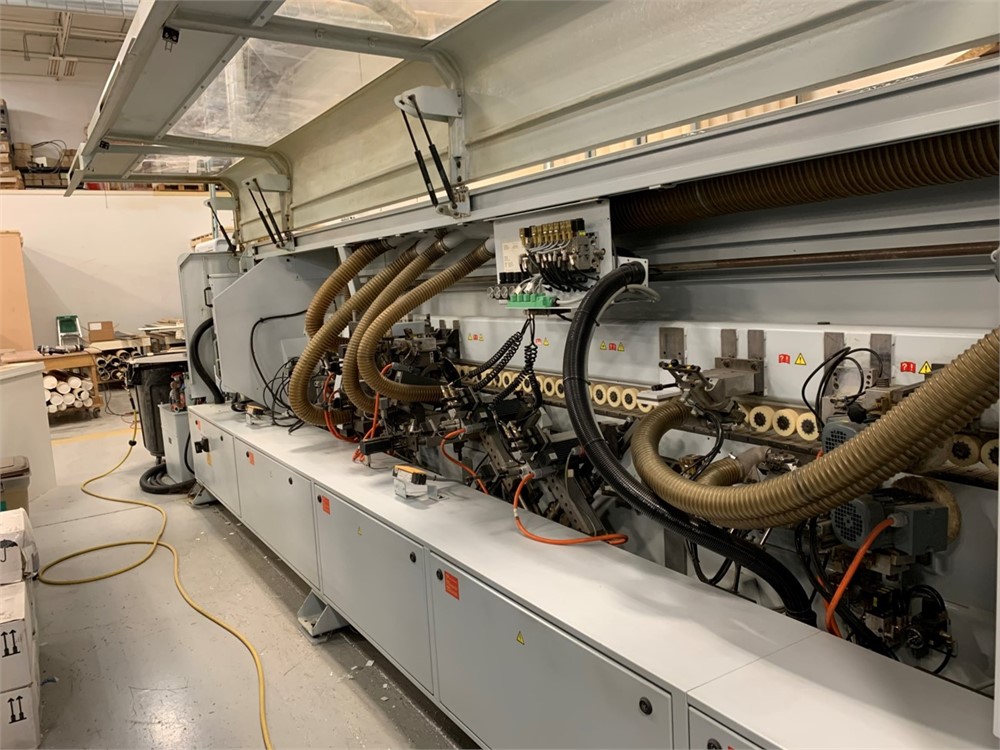

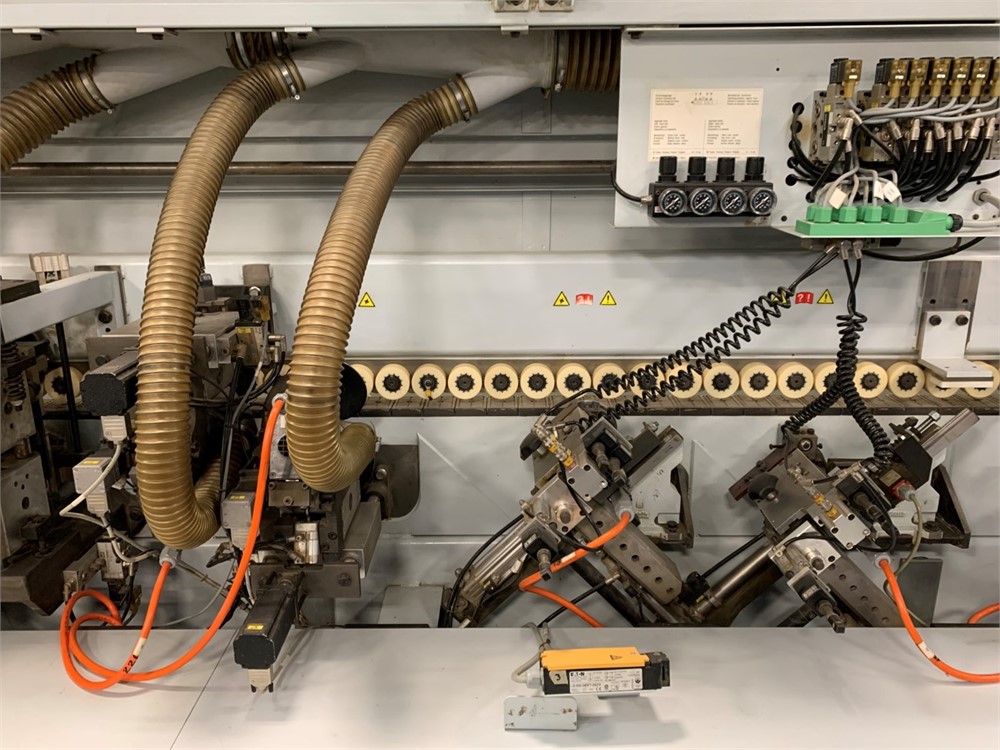

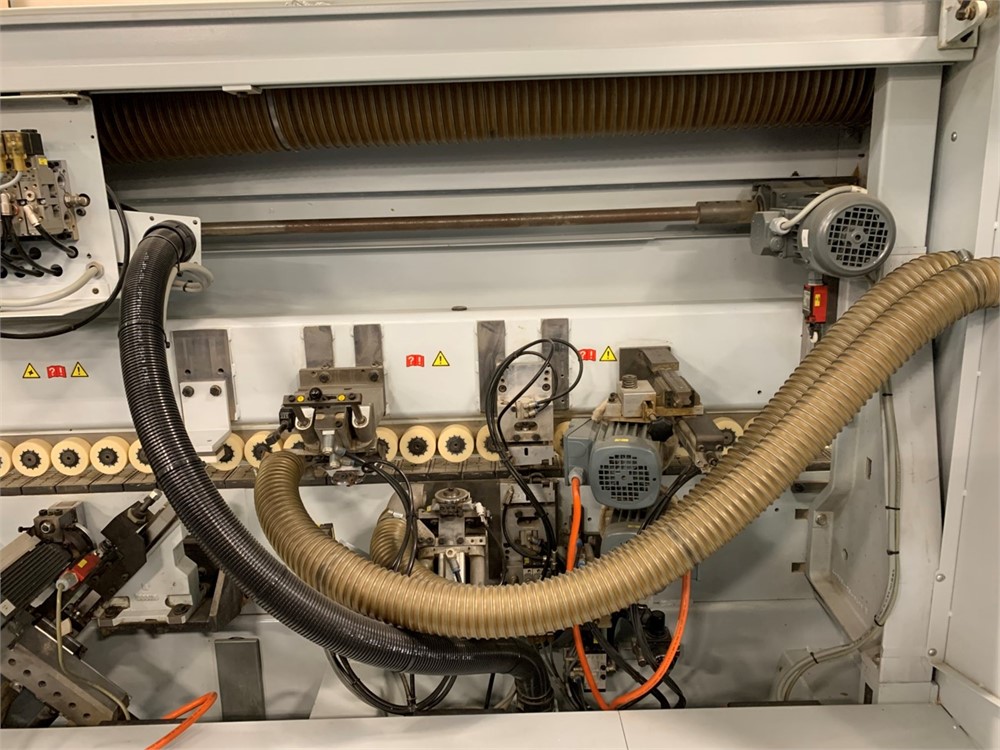

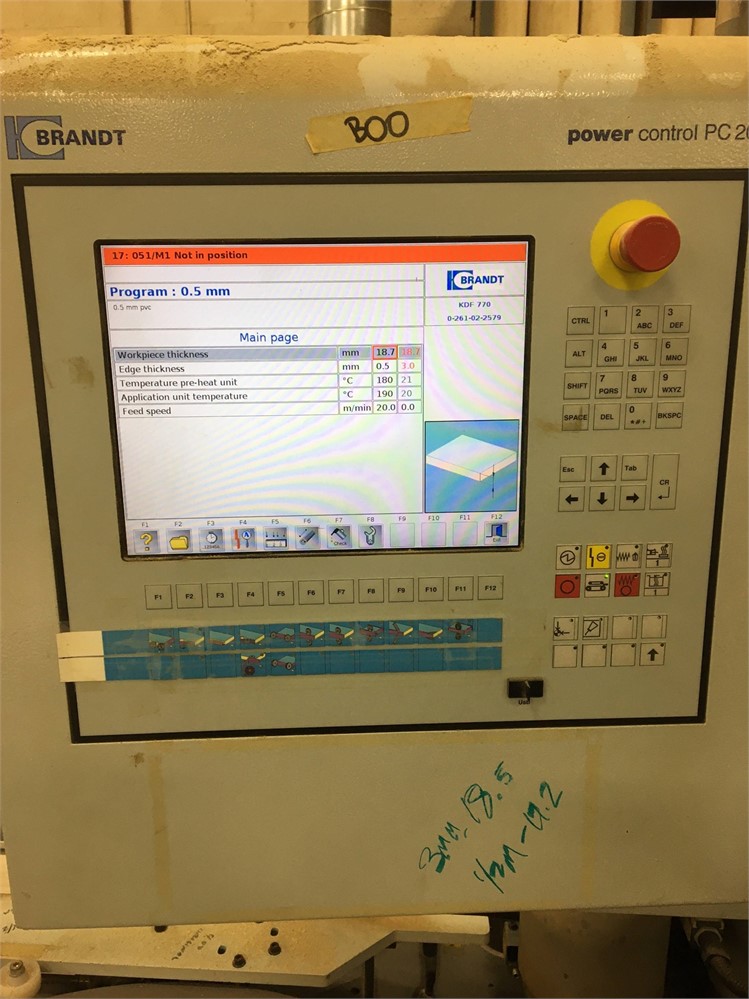

Closet manufacturer in Chicago, IL area is selling its edgebander. Brandt KDF-770 loaded with options: premill, quick-melt gluing system, end trimming, top/bottom rough trimming, top/bottom fine trimming, two motor corner rounding, profile scraping, glue scraping, buffing, servo control for multiple functions and more. Asset no longer required for continuing operations.

-

Item Location

150 S. Church St., Suite C Addison, IL 60101

-

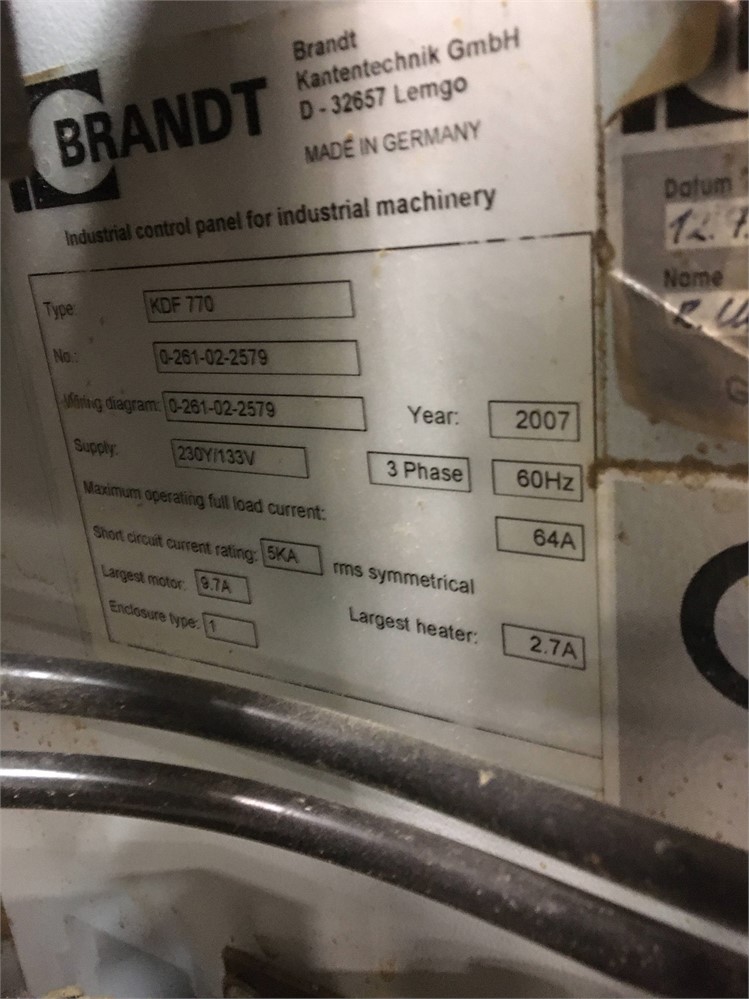

Make

Brandt

-

Model

KDF-770

-

Serial Number

0-261-02-2579

-

Year

2007

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Inspection Date

By appointment only, contact Jack Ragan

-

Final Removal Date

February 8 - February 12, 2021 (by appointment)

-

Estimated Dimensions

270" L x 65" W x 79" H

-

Estimated Weight

6,600 Pounds

-

Seller Comment

This lot requires a rigger, please contact Zipprich Machinery Movers @ 877-620-0062 or [email protected].

-

Load Fee

-

page views

5171

Brandt "KDF-770" Edgebander

0.4 mm - 15 mm (0.016" 0.625"), edgeband thickness

0.8 x 60 mm or 3 x 45 mm, maximum coil cutoff (PVC)

12 mm - 65 mm (0.5" - 2.6"), edgebanding height

160 mm (6.375"), minimum panel length

65 mm (2.5"), minimum panel width

8 mm - 60 mm (0.3" - 2.375"), panel thickness

Variable feed speed, 8 - 20 m/min (26 - 65 FPM)

Motorized height adjustment of top pressure beam

PC-20 controller with integrated line control system

Color Screen

Soft keys

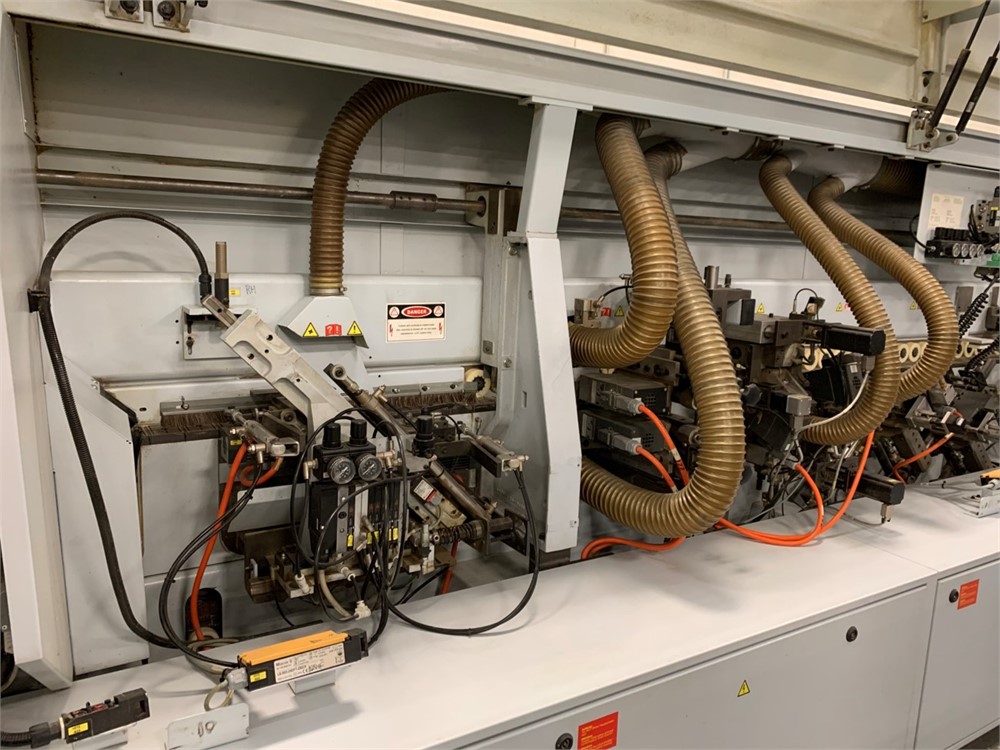

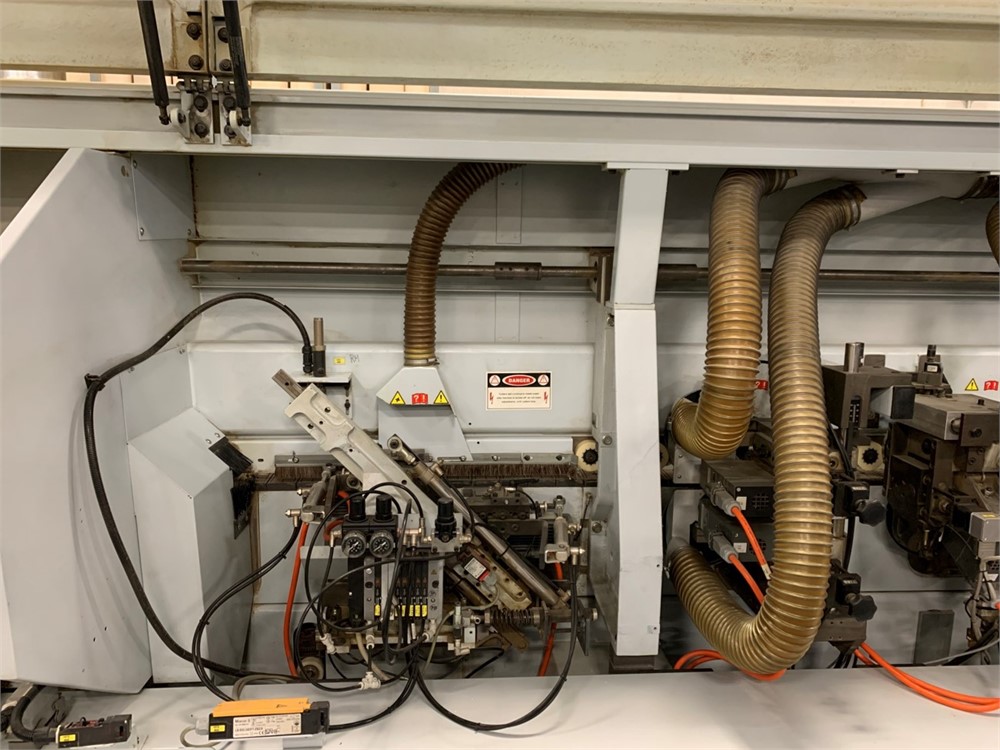

Premill

Two (2) 3 HP motors operating at 12,000 RPM

One (1) motor is CW rotation, one (1) motor is CCW rotation

Vertical spindle adjustment via digital settings

Horizontal positioning via electro-pneumatic control

Automatic magazine for strip and coil feeding

32" diameter coil table

Glue station

Quick-melt hopper with automatic glue feed system

Quick-change glue pot

Glue roller with reversible rotation

Infrared radiant glue heat zone control

Pressure station

One (1) driven pressure roller

Three (3) idle pressure rollers

Motorized adjustment via program control

End trimming station

Two (2) 0.5 HP motors operating at 12,000 RPM

Electronic motor brakes

Program controlled pneumatic indexing from straight to bevel end trim

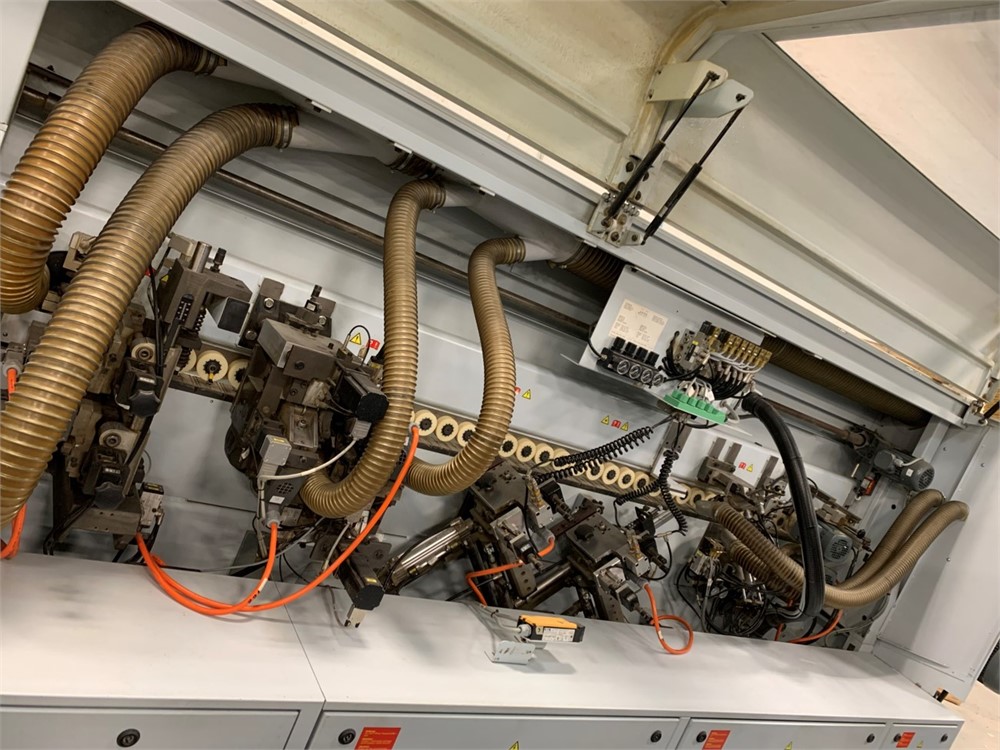

Top/bottom trimming station (flush)

Two (2) 0.75 HP motors operating at 12,000 RPM

Electronic motor brakes

Vertical tracing wheels with two position vertical indexing

Top/bottom trimming station (fine)

Two (2) 0.75 HP motors operating at 12,000 RPM

Electronic motor brakes

Horizontal and vertical tracing wheels

Auto tilt

Servo motor controlled positioning of work units and side copy to edge thickness

Corner rounding station

Two (2) 0.5 HP motors operating at 12,000 RPM

Electronic motor brakes

Operates at 52 FPM

Top/bottom scraping station

Program controlled pneumatic indexing

Top/bottom surface (glue) scraping station

Top/bottom buffing station

Two (2) motors operating at 2,800 RPM

Inclinable

Sound enclosure

Outboard roller support

External electrical transformer

Dust pipe NOT included

Specifications and configuration details were taken from seller-supplied photos and from manufacturer's literature. Bidder is encouraged to verify and/or inspect the machine.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.