2018 MarkForged "Metal X" 3D PrinterW/ Sinter-1, and Wash System  Ended

Ended

Located in Tracy, Ca

- Winning Bid : $67,150.00 USD Sold

- 70 Bid(s)

- High Bidder: m****7

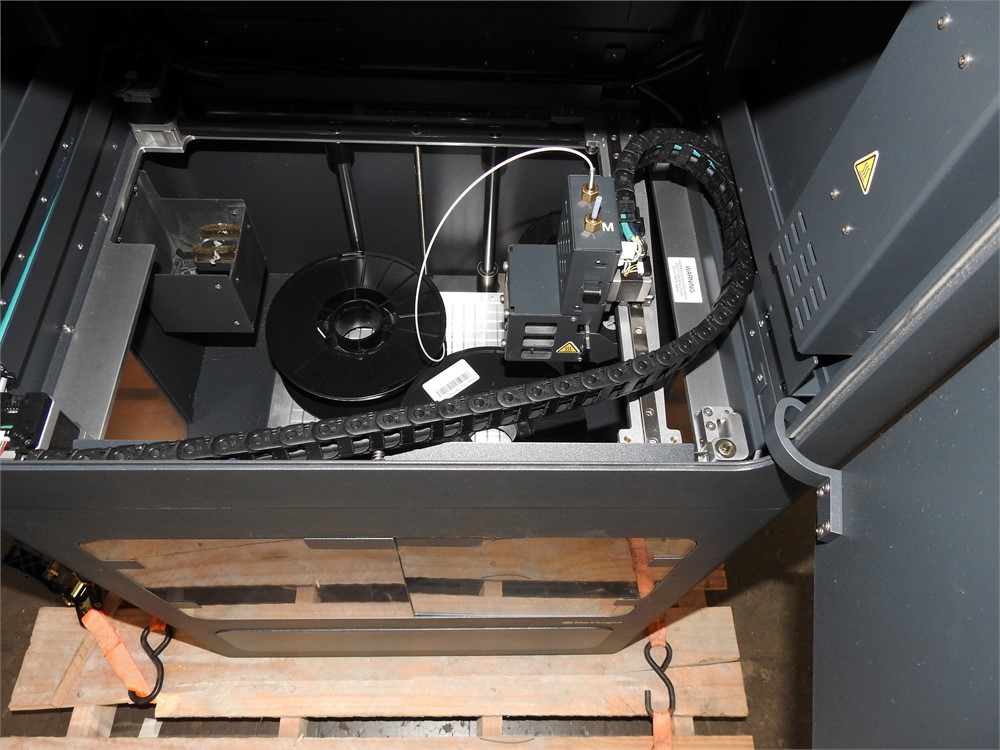

2018 MarkForged "Metal X" 3D Printer - Tracy, Ca ( Closed #22694400 )

Complete Metal x System w/ Sinter-2 and Wash System The Leading End-to-End Metal 3D Printing Solution Everything you need to go from design to fully functional metal parts — the Metal X is the best-in-class additive manufacturing solution.

-

Item Location

METAL X "TRACY, CA" SINTER-2/WASH "PHOENIX, AZ"

-

Make

MarkForged

-

Model

Metal X

-

Serial Number

de03f69e-b768-4cd6-ac1e-a89d94ae82be

-

Year

2018

-

Phase

1 PHASE

-

Voltage

110 VOLTS

-

Inspection Date

-

Final Removal Date

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

-

Load Fee

100

-

page views

3862

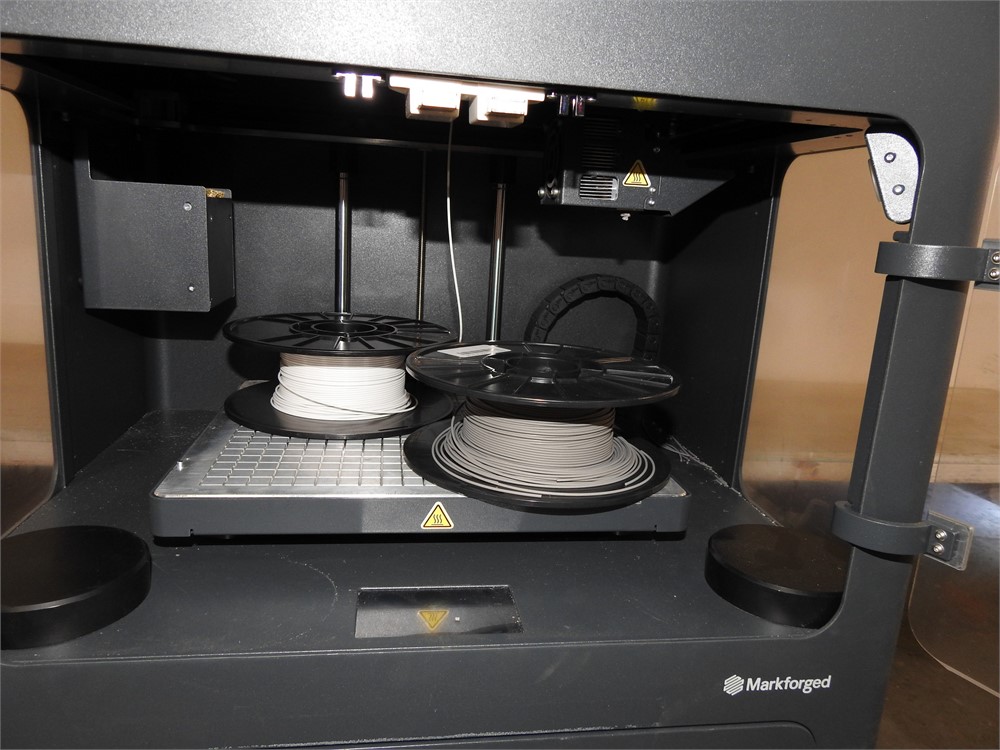

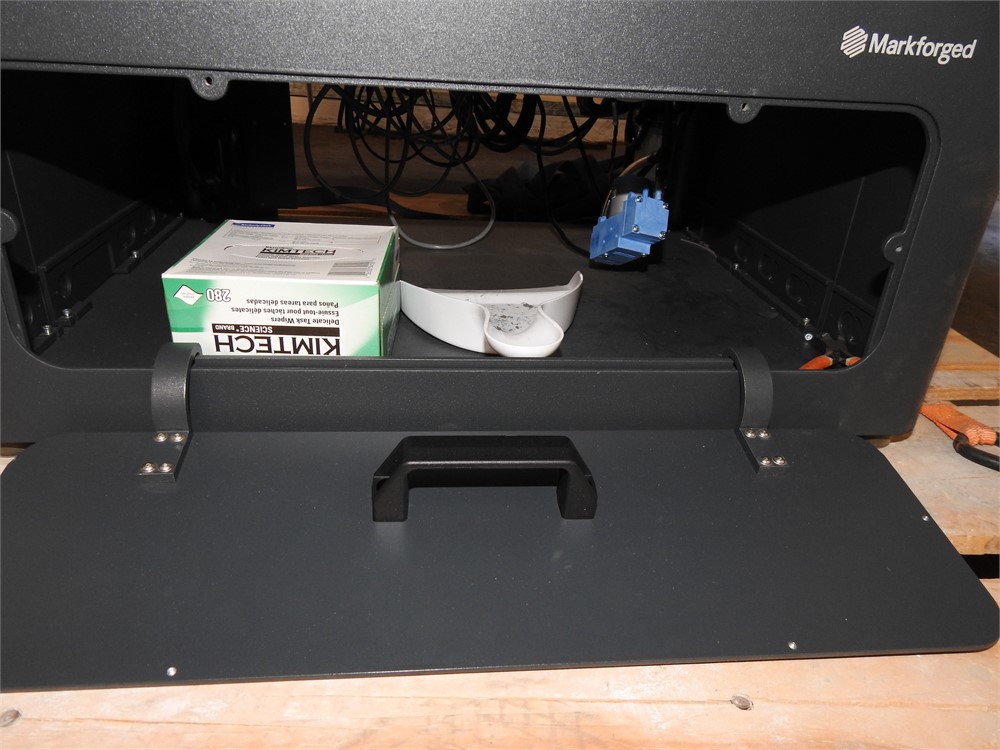

Complete Metal x System w/ Sinter-2 and Wash System

Metal X System

Build Volume:300 mm x 220 mm x 180 mm

Z-Resolution:50 um - 125 um

Media:Filament fed, bound powder

Ext. Footprint:575 mm x 467 mm x 1120 mm

Weight:75 kg

Power Req.:100-240 VAC, 2400 W

More details on https://markforged.com/metal-x/

The Leading End-to-End Metal 3D Printing Solution

Everything you need to go from design to fully functional metal parts — the Metal X is the

best-in-class additive manufacturing solution.

What Can You Do With a Metal X?

Manufacture Smarter with Custom Tooling

The Metal X metal 3D printer enabled a job shop to deliver parts to customers faster and at lower cost by quickly tooling up an automated bending cell.

Rapidly Prototype Metal 3D Printed Parts

Metal 3D printing allows Shukla Medical to get tools in the hands of surgeons faster. They prototype custom surgical tools like this helicopter socket in-house.

Bring Low-Volume Production in-House

Nieka Systems brought small-batch Inconel manufacturing in-house with a Metal X, eliminating lead time variability by removing reliance on a third-party DMLS print service.

Print Replacement Parts On-Demand

Stanley Black & Decker cut inventory and manufacturing costs by replacing casting with 3D printing for small-batch replacement parts.

Why Use a Metal 3D Printer?

Business Benefits

- Get products to market faster

- Reduce manufacturing costs

- Improve supply chain efficiency

Technical Advantages

- Easily 3D print complex geometries

- Eliminate tooling spend

- Safe, automated processes

Metal 3D Printing Materials

Combines high strength, corrosion resistance, and hardness. Used in a wide variety of manufacturing applications.

A hot-work tool steel with excellent toughness, wear resistance, and heat resistance. Excels in high temperatures.

Can be air-hardened up to 58 HRC; excellent impact resistance. Used for forming tooling, punches, and dies.

Can be air-hardened to 60 HRC; trades toughness for hardness and abrasion resistance. Great for cutting tools and dies.

A proprietary nickel alloy that excels in high temperatures and corrosive environments. Used in automotive and aerospace.

Thermal and electrical conductivity. Print heat sinks, custom conductive elements, and other geometrically complex parts.

Metal X

Built around a 5th-generation extrusion and motion system, the Metal X is office friendly, easy to use, and has a small footprint. It features advanced failure detection and can be monitored from the cloud.

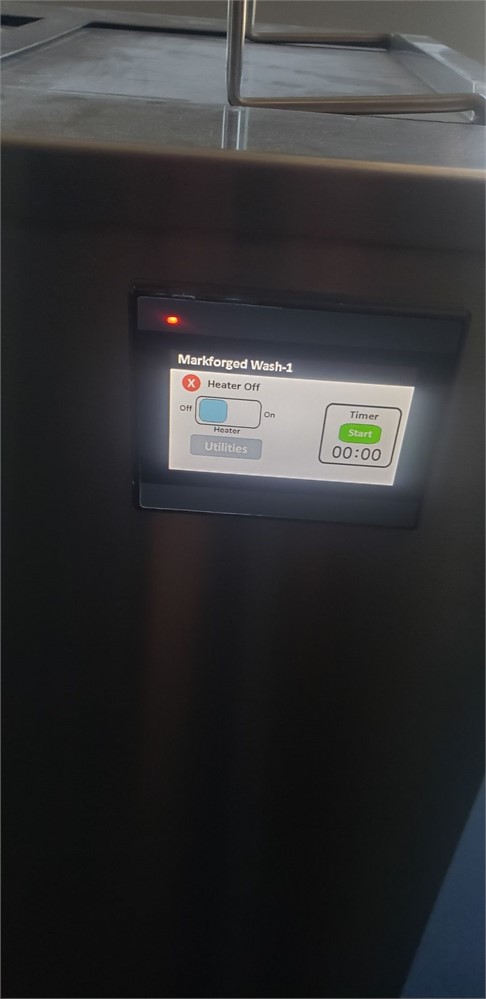

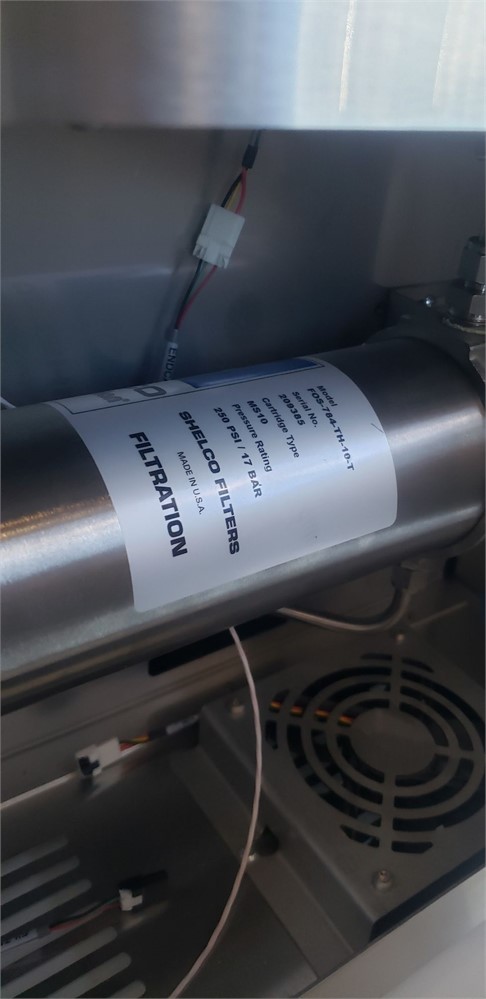

Wash-1

Optimized for efficiency, safety, and easy of use, the Wash-1 features integrated debinding and drying stations. Parts can be washed in parallel, allowing you to maximize throughput on a wide variety of part sizes.

Sinter-1

The Sinter-1 is a high-performance, high-value furnace ideal for smaller parts. Featuring a 4,760 cubic cm (290 cubic in) active hot zone, it can process any of Markforged’s materials in as little as 26 hours.

NOTE: THE WASH AND SINTER ARE LOCATED IN OUR PHOENIX, AZ WAREHOUSE

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.