MAGGI "SYSTEM 3/50" AUTOMATIC EDGEBANDER, YEAR 2016  Ended

Ended

MAGGI EDGEBANDER AUCTION, FRIDLEY MN

- Winning Bid : $5,520.00 USD Sold

- 78 Bid(s)

- High Bidder: c****s

MAGGI SYSTEM 3/50 EDGEBANDER AUCTION, FRIDLEY MN ( Closed #22376535 )

BY ORDER OF SECURED CREDITOR, AUCTION OF 2016 MAGGI SYSTEM 3/50 AUTOMATIC EDGEBANDER MACHINE. AUCTION CLOSES ONLINE @ MACHINERYMAX.COM STARTING @ 10:00 AM PACIFIC TIME ON WEDNESDAY, JULY 1ST, 2020. IF YOU HAVE QUESTIONS, PLEASE CONTACT KIRK @ 925-250-8248 OR VIA EMAIL @ [email protected]

-

Item Location

5101 INDUSTRIAL BLVD NE, SUITE #100, FRIDLEY MN 55421

-

Make

MAGGI

-

Model

SYSTEM 3/50

-

Serial Number

1851600276

-

Year

2016

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Inspection Date

BY appointment only, contact Kirk Gass 925-250-8248

-

Final Removal Date

JULY 8TH, 2020

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

Non Negotiable Load Fee 300

-

Load Fee

300

-

page views

1265

BY ORDER OF SECURED PARTY

MAGGI MODEL #SYSTEM 3/50 AUTOMATIC EDGEBANDER

230 VOLT, 3-PHASE

SERIAL #1851600276

The Maggi Edgebander is a glue pot edgebander designed for the small shop that wants quality edge banding results like the larger production machines

It is equipped with a New Electronic Control Panel with Soft Touch Controls that optimizes the work cycles ensuring precision and durability

- Edgeband capacity: 0.4 to 3mm Tape and 0.4 to 2mm Wood Strips

- Machine is equipped with a Teflon coated, round glue pot for more uniform heating of glue

- Includes a Quick Empty System for changing glue or cleaning

- 2 adjustable edge pressure rollers

- The glue pot has an automatic stand-by function and "ECO" significant energy savings from 400 watts to 48 watts

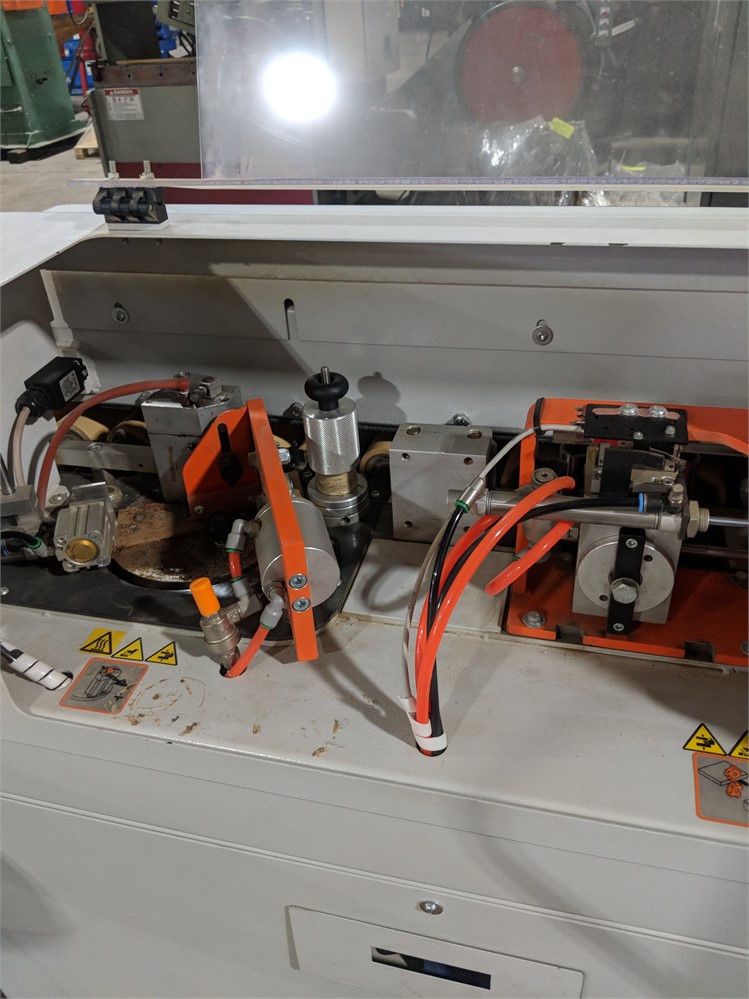

- End Trimming: Consists of (2) angled HSS guillotine knives on linear bearings with heated blower to remove any residues on the ends that are cut, includes drawer to collect end trim scraps

- Top and Bottom Trimming: Consists of (2) high frequency top and bottom trim motors with guides and linear bearings to provide precision control

- Also equipped with top and bottom hardened steel 90 mm copy wheels

- (2) 4-knife cutterheads with carbide double radius insert tooling - quick disassembly of the top and bottom trimmers to easily replace the cutters

- Glue reel support that folds down when not in use to save space

- Feed speed 21 FPM

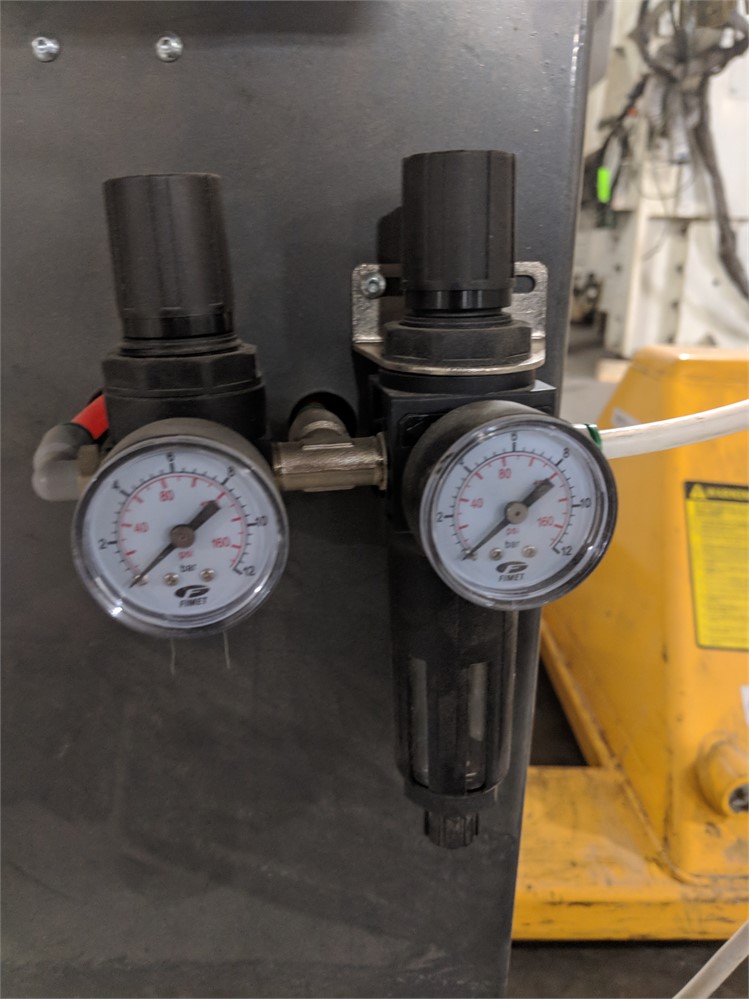

- 530 Minimum CFM @ Air Speed 65 FPS

- Minimum panel size: 3-1/2" x 7-1/2"

- Maximum panel size: 24.8" x 118"

- Minimum panel thickness: 1/2"

- Maximum panel thickness: 2"

- Dust port is 3"

- Machine dimensions: 100" L x 60" W x 47" H

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginA $250.00 LOADING FEE WILL BE ADDED TO WINNING BIDDERS INVOICE.

PAYMENT IS DUE WITHIN 24 HOURS OF AUCTION CLOSE TIME.