BRANDT "OPTIMAT KD-78/2C" AUTOMATIC EDGEBANDER, YEAR 2000  Ended

Ended

TRACY CALIFORNIA AUCTION, OVER 20 LOTS UP FOR BID

- Winning Bid : $4,050.00 USD Sold

- 22 Bid(s)

- High Bidder: M****a

TRACY, CALIFORNIA WAREHOUSE AUCTION 82, OVER 20 LOTS UP FOR AUCTION - Tracy, Ca ( Closed #21048650 )

TRACY CALIFORNIA 82 WAREHOUSE AUCTION CONSISTS OF OVER 20 LOTS THAT HAVE BEEN MOVED TO TRACY WAREHOUSE FOR THE CONVENIENCE OF BUYERS. AUCTION ITEMS INCLUDE BRAND NEW SAWSTOP JOBSITE SAW, BRAND NEW POWERMATIC 6" JOINTER, BRANDT EDGEBANDER, SCMI 43" SANDER, HOFFMAN DOVETAIL MACHINE, AND MUCH MORE. AUCTION CLOSES ONLINE AT MACHINERYMAX.COM STARTING @ 11:00 AM PACIFIC TIME ON TUESDAY, MARCH 24TH, 2020. IF YOU WOULD LIKE TO VIEW MACHINES PRIOR TO AUCTION CLOSE, PLEASE CONTACT [email protected] OR CALL THE MAIN OFFICE @ 209-832-0100

-

Pick Up Location

1905 N. MACARTHUR DRIVE, SUITE 110, TRACY CALIFORNIA 95376

-

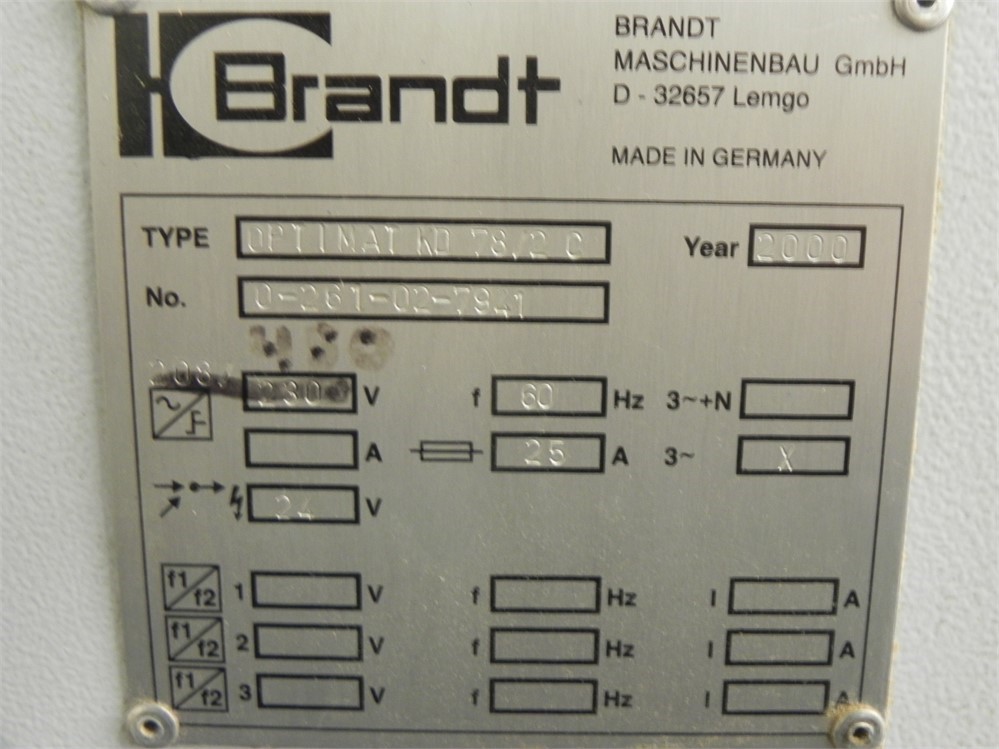

Make

BRANDT

-

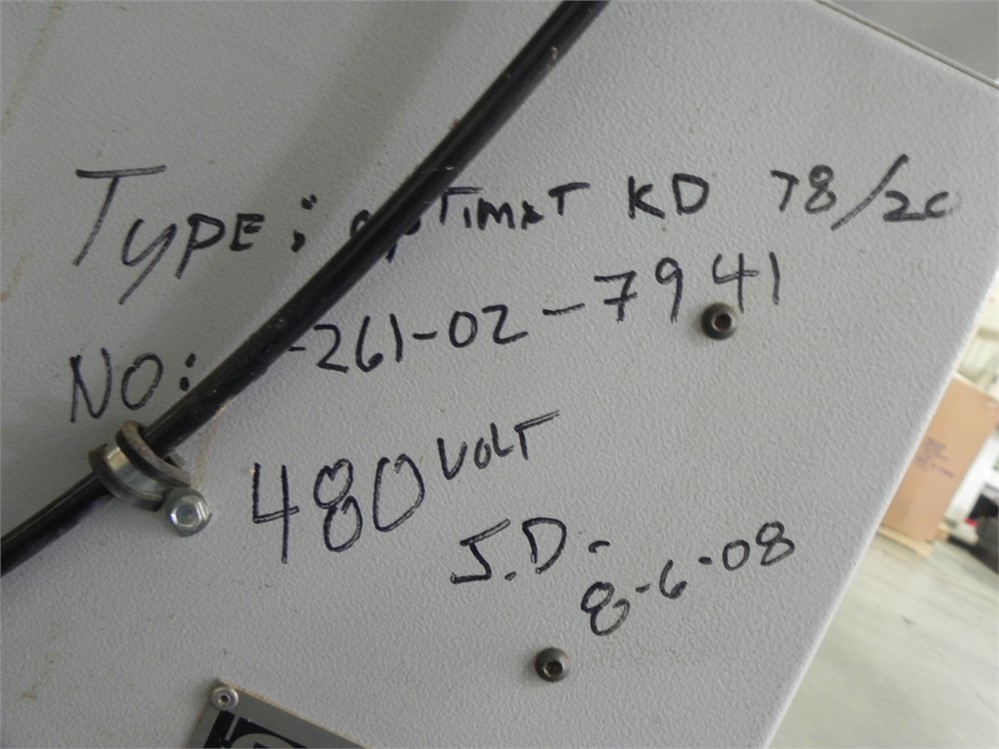

Model

OPTIMAT KD-78 2C

-

Serial Number

0-261-02-7941

-

Year

2000

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Load Out Period

APRIL 1ST, 2020

-

Estimated Dimensions

20' X 48" X 74"

-

Estimated Weight

APPROXIMATELY 4800 LBS.

-

Seller Comment

-

Load Fee

-

page views

1383

BRANDT MODEL #OPTIMAT KD-78/2C HEAVY DUTY AUTOMATIC EDGEBANDER MACHINE

YEAR 2000 BUILT MACHINE

208/230/460 VOLT, 3-PHASE MACHINE

SERIAL #0-261-02-7941

SPECS. AS PULLED FROM MANUFACTURER WEBSITE:

0.4 - 12mm (1/2") Edge cap., panel thickness 5/16" - 1-9/16", min. panel length 160 mm (6-3/8") and 65 mm (2-1/2") min. width; line control (NO limit switches) for workstation function. Automatic height adjustment with top pressure beam for all work station, equipped with digital height indicator.

PC-16 Program Control; with 7 1/2' VGA screen 8 MB IDE flash disk, 8 MB RAM, Internal Modem for remote diagnostic link; Signal infeed light to insure proper spacing between panels.

Equipped with: Quick heat-up glue system, "quick change" glue tank for maintenance & glue color change; reversible rotation glue roller w/infrared heat zone to follow.

Automatic magazine for strip & coil (Large coil table 800 mm diameter to accommodate large coils of 3 mm PVC) stock, 3 mm PVC guillotine, (1) drive plus (3) idle roll "pneumatically controlled" pressure sections.

Workstations: Double motor end trim (1/3 HP - 12,000 RPM motors), chamfers 0° - 15°; (2) Top & Bottom flush/"Hoggers" for Solid Wood and releif cutting to prepare for finish flush trimmers (saves tooling) (2) Two top & bottom flush/radius trim, bevels 0° - 15° (1/2 HP - 12,000 RPM motor), with insert knives for 3 mm PVC radius.

2-Motor corner rounding unit for top & bottom corners (0.5 HP - 12,000 RPM motors); top & bottom scraping for 2 - 6 mm radius, pneumatically controlled blowoff nozzles; top & bottom buffing (0.25 HP - 1,400 RPM motors).

- Manual Beam Adjustment

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginLOADING FEES WILL BE ADDED TO EACH LINE ITEM SO PLEASE CHECK LOAD FEES ASSOCIATED WITH ITEMS THAT YOU ARE BIDDING ON. LOAD FEES ARE FOR LOADING ONTO FLAT BED TRUCK OR TRAILER ONLY.

PAYMENT IS DUE WITHIN 24 HOURS OF AUCTION CLOSE TIME. CREDIT CARD WILL BE ACCEPTED FOR PAYMENT FOR INVOICES UNDER $2000.00 HOWEVER A 2% PROCESSING FEE WILL BE ADDED TO THOSE INVOICES PAID VIA CREDIT CARD. ALL INVOICES OVER $2000 REQUIRE WIRE TRANSFER, CASHIERS CHECK, CASH, OR APPROVED COMPANY CHECK.

PLEASE CONTACT SABRINA @ 209-832-0100 WITH ADDITIONAL PAYMENT QUESTIONS.