MARTIN "T70" PROGRAMMABLE SLIDING TABLE SAW, YEAR 2014  Ended

Ended

OVER 40 LOTS UP FOR BID, TRACY CALIFORNIA

- Winning Bid : $25,100.00 USD Sold

- 51 Bid(s)

- High Bidder: N****C

TRACY, CALIFORNIA WAREHOUSE AUCTION 76, OVER 40 LOTS UP FOR AUCTION - Tracy, Ca ( Closed #18764935 )

TRACY CALIFORNIA WAREHOUSE AUCTION 76. ALL ITEMS MOVED TO TRACY CALIFORNIA WAREHOUSE FOR CONVENIENCE OF BUYERS. ITEMS UP FOR AUCTION INCLUDE 2014 MARTIN T70 PROGRAMMABLE SLIDING TABLE SAW, 2019 MARCON LIFT TABLE, SEVERAL SCM AND MINIMAX NEW MINOR SCRATCH AND DENT MACHINES, BIESSE 2003 FLAT TABLE ROUTER, TONS OF TOOLING, AND MUCH MORE. *AUCTION WILL CLOSE ONLINE AT MACHINERYMAX.COM STARTING @ 11:00 AM PACIFIC TIME ON THURSDAY, NOVEMBER 14TH, 2019. **IF YOU WOULD LIKE TO VIEW MACHINES PRIOR TO AUCTION CLOSE, PLEASE CONTACT 209-832-0100 OR EMAIL [email protected]

-

Item Location

1905 N. MACARTHUR DRIVE, SUITE 110, TRACY CALIFORNIA 95376

-

Make

MARTIN

-

Model

T70

-

Serial Number

528064

-

Year

2014

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Inspection Date

EMAIL [email protected] OR CALL 925-250-8248

-

Final Removal Date

NOVEMBER 22ND, 2019

-

Estimated Dimensions

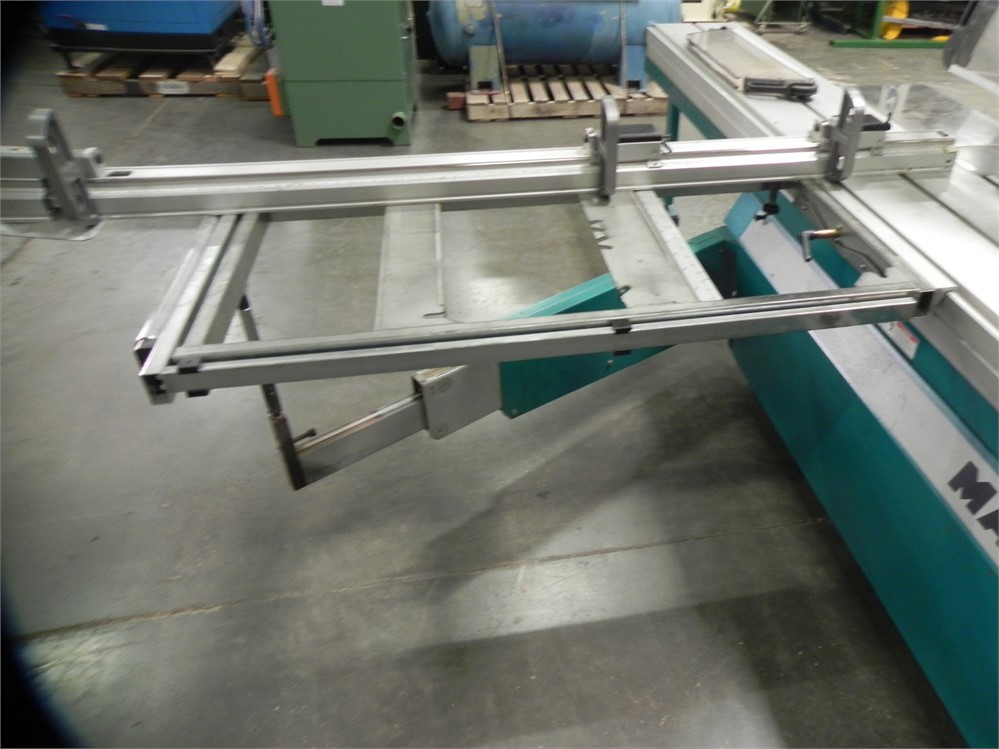

176" X 88" X 72"

-

Estimated Weight

APPROXIMATELY 3500 LBS.

-

Seller Comment

-

page views

2985

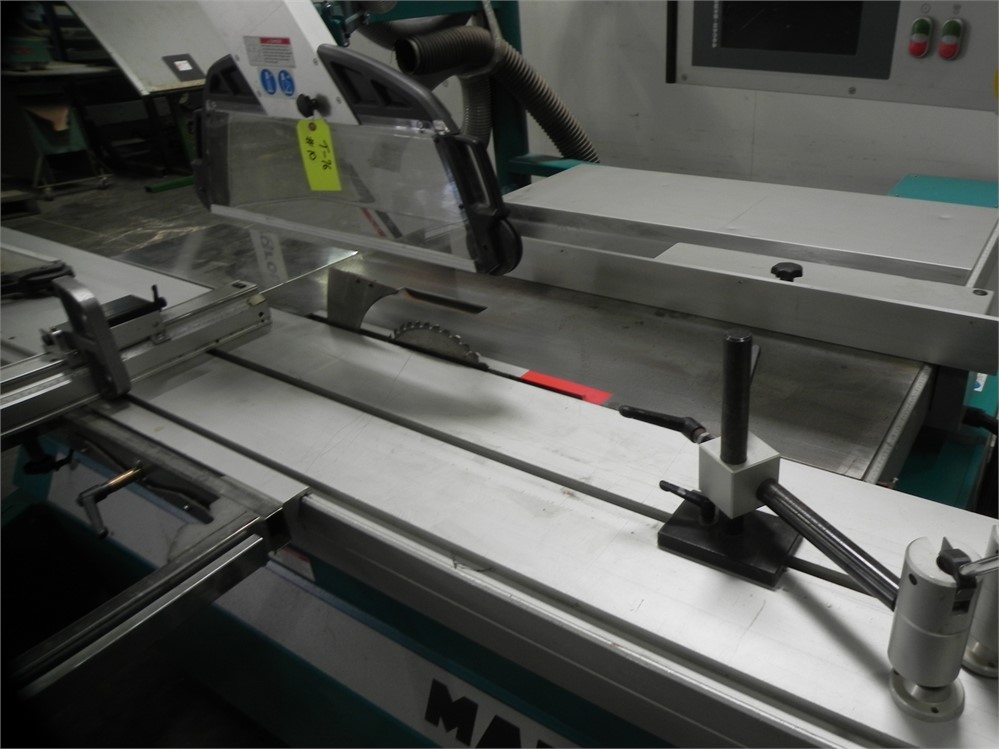

MARTIN MODEL #T70 PROGRAMMABLE SLIDING TABLE SAW

YEAR 2014 BUILT MACHINE

230 VOLT, 3-PHASE MACHINE

SERIAL #528064

**SPECS. AS PROVIDED VIA MANUFACTURER WEBSITE, PLEASE DO OWN DUE DILIGENCE AS TO EXACT SPECS. OF THIS MACHINE:

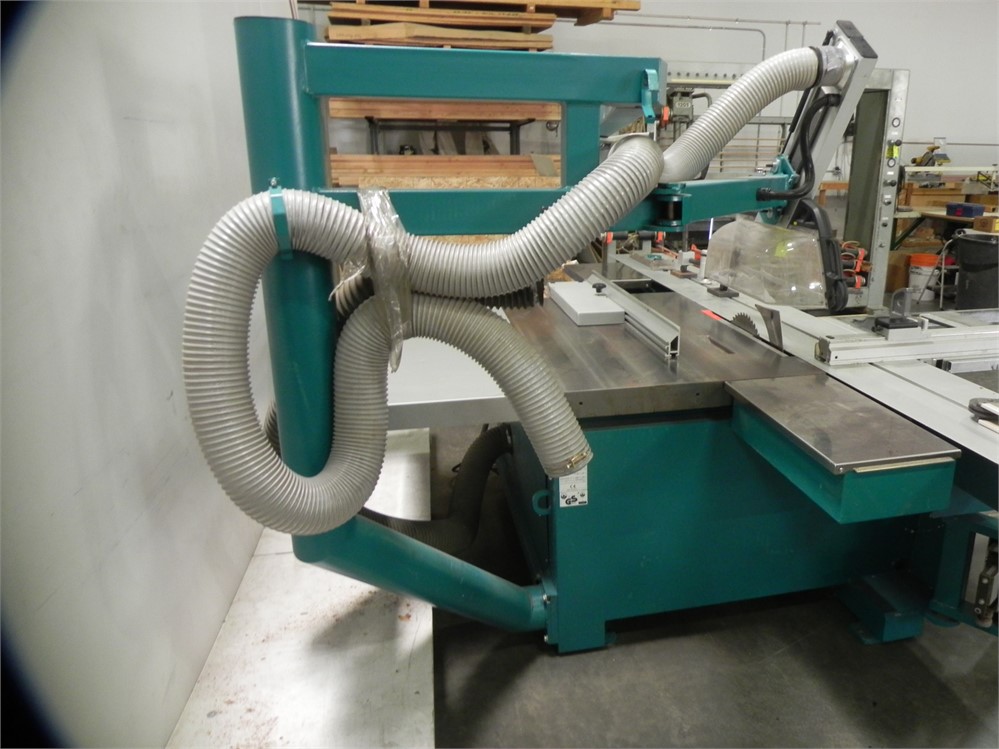

T70 Sliding Table Saw

A classic machine which has set standards for us. Now also for you.

Like any Martin, the T70 is built for maximum performance inside and out. The sturdy mechanical design is complemented perfectly by the unique user-friendliness of the sophisticated 10.4“ touchscreen controller. The reason for this is that we not only set standards in technology but also in operation: You are appropriately guided through all the operating and work processes – even individually customized if desired.

Electrically adjustable 2-axis and 3-axis scoring saw

The 2-axis system is completely user-friendly. Full integration into the touchscreen controller facilitates the input of all necessary settings. The left/right positioning of the scoring saw in relation to the right shoulder of the main blade and the scoring height is adjusted automatically. The kerf width is adjusted with stacked shims. If you combine the 2-axis scoring saw with the T7022 ScribeMaster saw blade system, the kerf width can be adjusted in a matter of seconds. With inserted scoring saw blades you can use main saw blades of up to 400 mm in diameter. If you remove the scoring saw blades and the flange you can easily work with saw blades of up to 550 mm in diameter. The patent-pending MARTIN 3-axis scoring saw system is fully integrated into the controller and facilitates the input of all necessary settings. The fully integrated scoring saw is linked to the touchscreen’s tool menu, allowing the automatic positioning of the scoring saw width to match every main saw blade that has previously been entered into the controller. The system needs to be calibrated only once. Time-consuming sample cuts are avoided almost completely. Thanks to a quick clamping system the scoring unit of the 3-axis scoring saw can be completely removed or changed within seconds. This is important, especially if you want to use saw blades in excess of 400 mm in diameter.

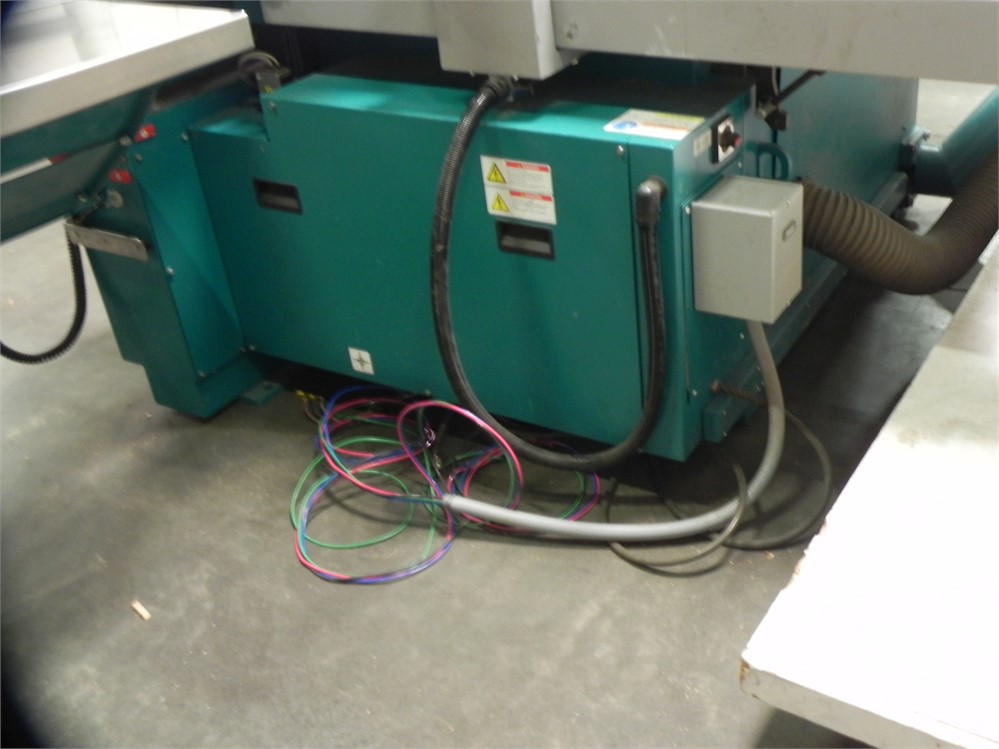

Solid machine frame

The T70’s solid and heavy machine frame that is reinforced with a concrete composite is unique and in the woodworking machinery industry only to be found on MARTIN machines with this technical perfection. Otto Martin invented this method of construction in the 1920s and had it registered as a patent back then. Today, after 90 years of continual improvement, MARTIN still uses this simple and effective type of frame construction. The combination of steel and concrete create a high-quality machine frame that is unparalleled when it comes to sturdiness, absorbing capacity and torsion resistance. This design has been proven to have up to six times the vibration dampening properties than that of a traditional cast-iron or welded.

Easy to operate

To enter a new value for a particular axis into the controller, just touch the respective number field. The screen immediately changes its input mode, enabling you to enter new numerical values. The numeric keypad not only indicates the minimum and maximum allowable input values that the machine will take but also memorizes the last five input values for rapid recall. The integrated calculator can also be used if necessary. On the „HOME“ page, rapid access icons can be created and unused icons can be deleted. This way you can keep track of the current machine values. For the precision calculation of your cuts and quick tool change, you can store up to 100 different saw blades in the tool menu. A saw blade that has been stored once is immediately available and fully integrated into the controller. This way the 3-axis scoring unit automatically adjusts to the kerf of the main saw blade. Time-consuming test cuts can be omitted almost completely and you can concentrate on the task at hand.

VacuSlide workpiece clamping system

VacuSlide is an efficient and intelligent clamping system for panel material made of wood, plastic or non-ferrous metals. It offers excellent performance especially if thin and/or delicate materials have to be clamped or bevel, as well as mitre cuts, have to be made. Workpieces up to 110 mm wide can be securely clamped. Preselection is not necessary. VacuSlide is activated or deactivated via radio remote control. Delivery includes vacuum generator, remote control, reverse flow filter as well as low-pressure warning device. Cannot be used in combination with the motorized sliding table or when the rip fence is set via hand wheel.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginLOADING FEES WILL BE ADDED TO EACH LINE ITEM SO PLEASE CHECK LOAD FEES ASSOCIATED WITH ITEMS THAT YOU ARE BIDDING ON. LOAD FEES ARE FOR LOADING ONTO FLAT BED TRUCK OR TRAILER ONLY.

PAYMENT IS DUE WITHIN 24 HOURS OF AUCTION CLOSE TIME. CREDIT CARD WILL BE ACCEPTED FOR PAYMENT FOR INVOICES UNDER $2000.00 HOWEVER A 2% PROCESSING FEE WILL BE ADDED TO THOSE INVOICES PAID VIA CREDIT CARD. ALL INVOICES OVER $2000 REQUIRE WIRE TRANSFER, CASHIERS CHECK, CASH, OR APPROVED COMPANY CHECK.

PLEASE CONTACT SABRINA @ 209-832-0100 WITH ADDITIONAL PAYMENT QUESTIONS.