SCM "Pratix S15B" CNC Router  Ended

Ended

Located in Elk Grove, Ca

- Winning Bid : $35,151.00 USD Sold

- 81 Bid(s)

- High Bidder: s****s

SMG Custom Cabinets - Complete Shop Closure - Elk Grove, Ca ( Closed #18562793 )

PLEASE NOTE ADDRESS FOR INSPECTION: 9755 KENT STREET ELK GROVE, CA 95624

PLEASE NOTE LOAD OUT DAYS: WED NOV 06 - TUESDAY NOV 12 (EXCEPT SUNDAY)

-

Item Location

9755 KENT ST SUITE 100 Elk Grove, Ca

-

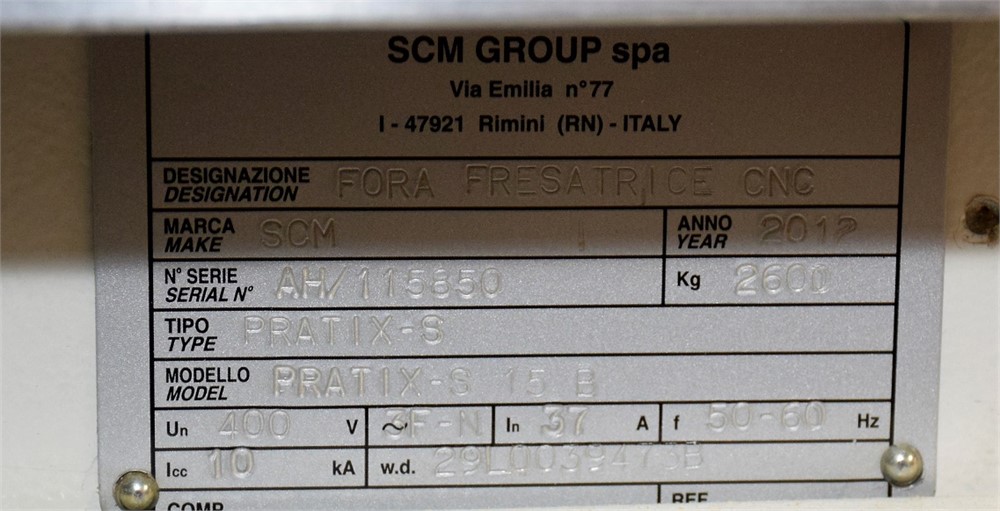

Make

SCM

-

Model

Pratix S15B

-

Serial Number

AG/115850

-

Year

2012

-

Phase

3 PHASE

-

Voltage

380/400

-

Inspection Date

MONDAY, NOV 04 (10AM-3PM)

-

Final Removal Date

TUESDAY, NOV 12

-

Estimated Dimensions

-

Estimated Weight

6,000 LBS

-

Seller Comment

BUYER RESPONSIBLE FOR HIRING A RIGGER FOR REMOVAL

-

page views

4209

-

Machine Operation

Machine Operation is accomplished through the use of an extremely flexible Universal Remote Pendant. The 7” COLOR display allows for the effective management of all machine functions from movement of controlled axes in Manual Jog Mode to loading and execution of a program. The unit is also fitted with a USB Port, which allows for a quick load and setup of new programs.

-

-

(63.03.57) Mobile stand panel with Stand-alone PC

It allows the programming directly on the machine without necessity of the programming in the office.

It is equipped with:

-

Personal Computer

-

Windows XP operating system available in the following languages: Italian, English, German, French, Spanish.

-

17” LCD colour display Qwerty keyboard Mobile control panel Xilog Plus machine interface software(63.01.27)

-

Electric cabinet with Air Conditioning deviceIt maintains temperature of approx. 65°F inside the electric cabinet.

-

-

(63.03.84) Ventilation system on machine base

It is particularly suitable for hot climates and for the use of materials sensitive to the heat; this ventilation system and base insulation ensure a low temperature of the working table.

-

-

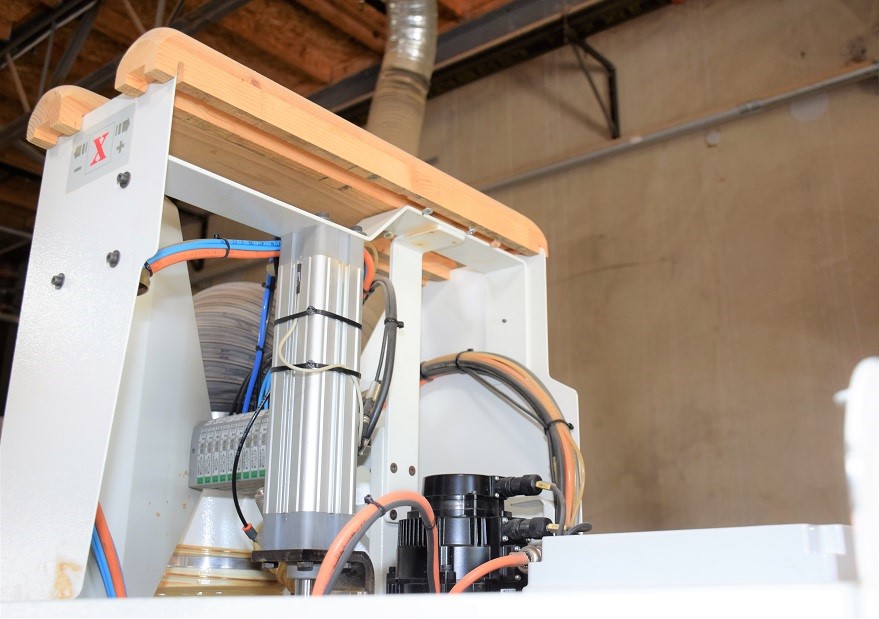

9HP (S6) Routing Unit

It includes:

-

HSK F 63 quick release tool-holder

-

1500 - 24000 rpm spindle speed

-

S1/S6) 5,5/6,6 kW (7,5/9Hp) constant motor power from 12000 to 18000 rpm

-

Right and left rotation

-

Static inverter for continuous speed and rapid shutdown of rotation

-

Exhaust hood around whole perimeter

-

N.B. Tool-holders and expansible collets are not included

Presetting for angular-driven heads

(63.03.44) Air blowers on the electrospindle

No.4 air blowers capable to convey the chips produced by the cutter during machining.. This facilitates the chip ejection.

(63.03.54) Touch Probe

Electronic system positioned on the base side which allows for detecting tool length without running a test program.

-

10 Position tool Changer

-

-

No 7 Inependent vertical spindles (no.4 right and no.3 left)

-

Attachment for bits: M10 / 11 mm diameter

-

Center-to-center distance between axes: 32 mm

-

Rotation speed: 4.000 rpm

-

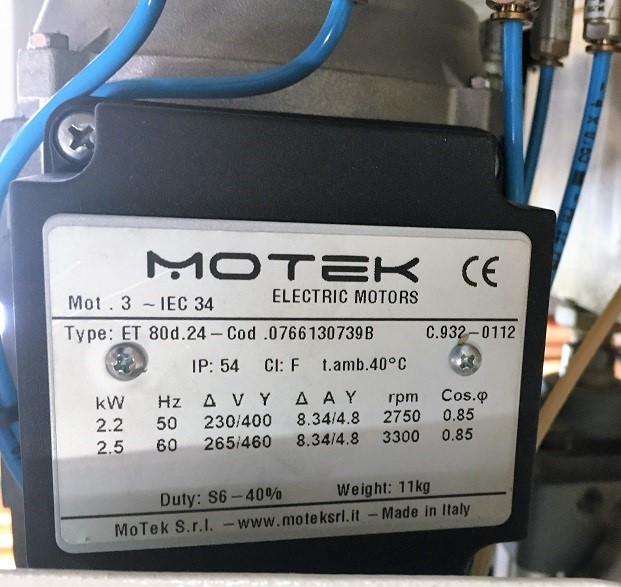

2,2 kW motor power

-

Pneumatic vertical ON/OFF stroke of whole unit

-

Pneumatic vertical ON/OFF stroke of each spindle: 60 mm

-

-

Inverter for boring head

It allows the rotating speed programming up to 6000 rpm maximum for the drilling bits and 7500rpm for the blade, exploiting the same inverter of the electrospindle.

Worktable for Component Nesting

High capacity aluminum table, with dual vacuum areas has an answer to most component nesting scenarios. The Vacuum holes set at 120 mm pitch, closure by means of rapid magnetic system “patent pending”. Grooves are set at 20mm from each other for fixing of the workpiece using rubbers seals.

In addition to nesting full sheets, the Pratix S15 can also be used for routing smaller components. For work on the face of the component, rubber gasket material can be used to isolate the vacuum for part hold-down. This eliminates the need for special fixturing devices as is necessary on many machines. When machining the edges of parts, the patented MODULSET system raises the component so work can take place without damage to the worktable.

The magnetic system for opening and closing the vacuum passages allows for an extremely quick table set up when the vacuum is only required in a portion of the table. With a dedicated tool (supplied) it is a matter of seconds to perform the set up with no need for a screw driver.

3 Right stops for “D” field of which no. 1 Side stop and no. 2 Rear Stops. (63.03.53) 3 Left stops for "A" field of which no. 1 Side Stop and no. 2 Rear Stops

(1) 300 Cubic Meter/Hour Vacuum Pump (Total 600 m3/hr)

The vacuum hold-down system features two 300 cubic meter/hour vacuum pumps. It offers the reliability of a substantial increase in vacuum power and allows the use of spoil boards for nesting full sheets.

(63.03.43) Autotransformer

Autotransformer allows the choice of 208 / 230 or 460 volt, 3-phase, 60 cycle

Safety Bumpers

The SCM Pratix S15 is equipped with Bumpers on both sides of the mobile unit. This system allows for safe movement near the machine while saving floor space by eliminating peripheral protection normally required.

TECHNICAL SPECIFICATIONS:

Worktable dimensions: Length

W idth

3686 mm (145.11”) 1555 mm (61.22")

Spindle (main) motor: Power (7) spindles Spindle rotation speed

3 HP 6000 RPM

Electrospindle

7.5 HP / 9HP, air cooled (S1/S6 rating)

Tool Changer Positions

Attachment

10 position - Side attached to machine base HSK 63

Drilling Unit

No. of vertical spindles

(Optional) No. of horizontal spindles (Optional) Grooving blade5 in X-axis , 2 in Y-axis 1+1 in X, 1+1 in Y Fixed in X direction

Maximum positioning vectorial speeds: X & Y axis

35 meters/minute (115 feet/minute)

Z axis Stroke Panel passage

250mm (9.84’) 150mm (5.90”)

Dust extraction required

3000 CFM

200 mm (7.87”) RouterOperating air pressure (3/4" I.D. hose)

7 ATM (102 psi)

Installed power (dependent upon options)

23 – 28.5 KVA

Electrics

208/230/460 volts, 3-phase balanced, 60 cycles

PC Specifications (minimum): Operating system

MonitorWindows XP Professional 17” Flat Panel

-

-

-

-

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.