LOT # 002 ANDERSON / GIBEN WIBJ-5 CNC STRYKER yr 2012  Ended

Ended

UNIQUE STORE FIXTURES 554 MILLWAY AVE CONCORD, ON L4K 3V5

- Winning Bid : $5,250.00 CAD Sold

- 8 Bid(s)

- High Bidder: D****3

UNIQUE STORE FIXTURES (28) LOTS EQUIPMENT NO LONGER NEEDED - CONCORD, ON CANADA ( Closed #17931243 )

ALSO UP FOR BID: DENVER SKEMA 15HP BRIDGE SAW * ADA 3713 GLASS MITRE AND POLISH MACHINE * ADA 1070 GLASS DRILLING MACHINE * HOLZHER 1270 SUPERCUT VERTICLE SAW * VITAP ALFA35T CONSTRUCTION BORER * OMGA TR2B DOUBLE MITRE SAW * BIESSE ROVER 30L2 CNC MACHINE * GIEFFE GLASS 500 SAW * SCM T130P SHAPER * SCM T130 SHAPER & FEEDER * CASADEI EMA FV-110 SHAPER & FEEDER * ATLAS COPCO GA10 SCREW AIR * TOYOTA 7FGCU30 FORKLIFT * HYSTER S50XM FORKLIFT * TCM CASADE SS FORKLIFT * COMPRESSOR * ATLAS COPCO GA30-125 SCREW AIR COMPRESSOR * PROGRESS PMC 150 EDGESANDER * JLT 79K-7 CLAMP * DELTA & GENERAL DRILL PRESSES....

-

Item Location

554 MILLWAY AVE CONCORD, ON L4K 3V5

-

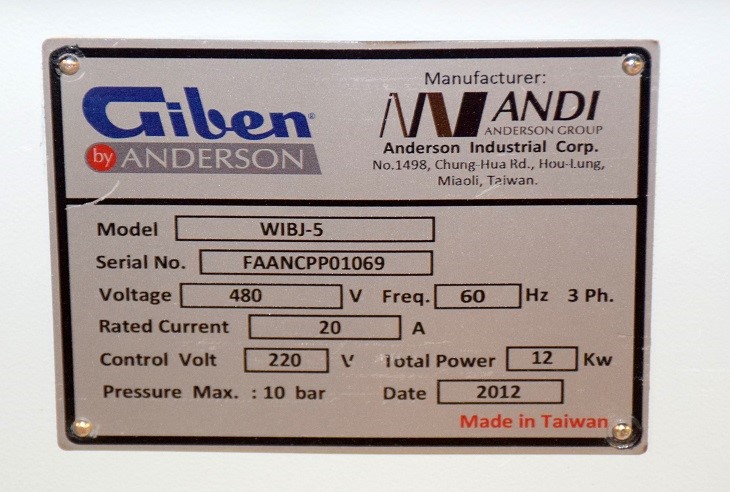

Make

GIBEN / ANDERSON

-

Model

WIBJ-5

-

Serial Number

FAANCPP01069

-

Year

2012

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Inspection Date

BY APPOINTMENT CALL ROBERT AT (416) 904-2475

-

Final Removal Date

FRIDAY, OCT 04, 2019

-

Estimated Dimensions

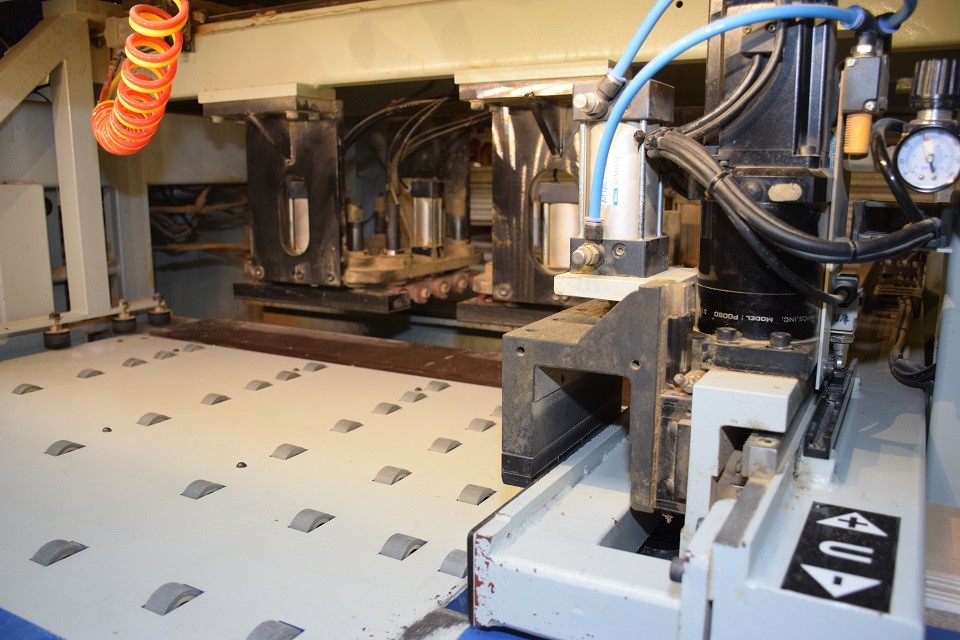

SEE PHOTO

-

Estimated Weight

COMING SOON

-

Seller Comment

SEE SHIPPING DETAILS

-

page views

2778

GIBEN /ANDI Model WIBJ STRYKER

Automatic CNC through-feed Point to Point boring machine that combines flexibility and high productivity;

A perfectly suited solution for small to mid-size companies & artisans in need of an automatic solution for precision drilling with a low cost investment.

Parts can be discharged at the opposite end of the machine for automated material handling or returned to the operator for manual unloading. Working Field:

Max. panel size "X" Axis 98.4" (2,500 mm), "Y" axis 33.4" (850 mm), "Z" axis 2.3" (60 mm);

Min. panel size "X" axis 7.9" (200 mm), "Y" axis 2.8" (70 mm), "Z" axis 0.39" (10 mm).

Positioning Speed:

"U" axis Panel feeding speed 197 FPM (60 MPM), "X" & "Y" axis 197 FPM (60 MPM), "Z" axis 49 FPM (16 MPM);

Axes positioning by AC drives & brushless motors; the "Panel" moves in "X" axis & the "Machining Units" move in "Y & Z" axis.

Work area:

NC Controlled "Optical Material Sensor" creates a “0“ panel reference point by reading the panel's ends; this ensures that RH & LH (mirror image) panels will always be symmetrical.

Fixed RH ("U" axis) panel clamping device with automatic panel adjustment according to the programmed information;

LH side pressure clamp with automatic adjustment & pneumatic locking according to the panel width;

Scratch resistant idle rollers for panel positioning from the bottom & sides.

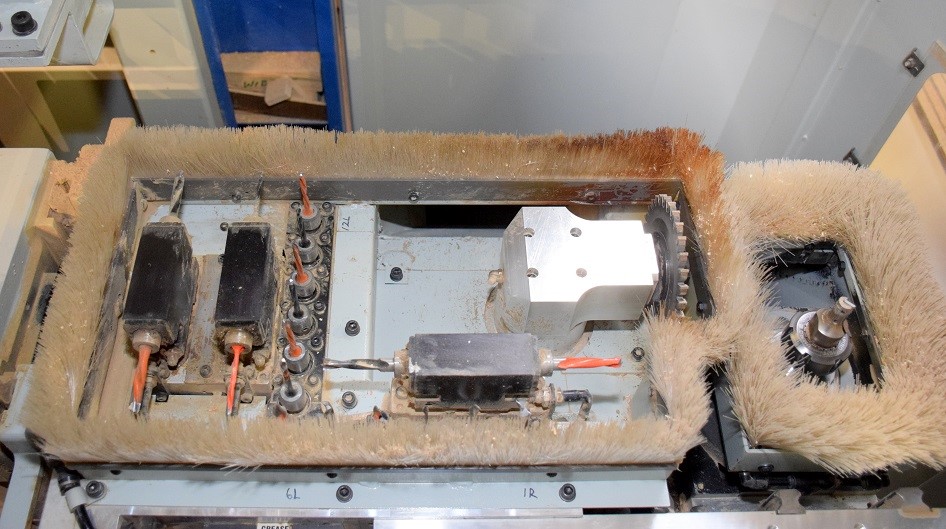

Boring unit:

2 HP (1.5 kW) - 4,800 RPM motor; (12) Independent vertical spindles with (6) in "X" axis & (6) in "Y" axis;

(6) horizontal spindles with (2+2) in "X" axis & (1+1) in "Y" axis, (1) 4,200 RPM "X" axis grooving saw with max. 120 mm dia blade.

Max. dia. of horizontal drill bits 12 mm, max. dia. of vertical drill bits 35 mm, max. drilling depth 43 mm

Machining:

(1) 5 HP (3.7 kW) electro-spindle router with ER 25 collet adaptor, variable speed from 1,000 - 18,000 RPM, 16 mm max. tool dia.

Operator & Machine Control:

User friendly, Icon driven & fully Parametric control housed on a control console mounted to the machine base;

17" LCD display, keyboard & mouse with network card and USB; displays programming graphics, functions, machine data & subroutines;

Capable of running production while programming and editing.

Complete with: User's & maintenance manuals.

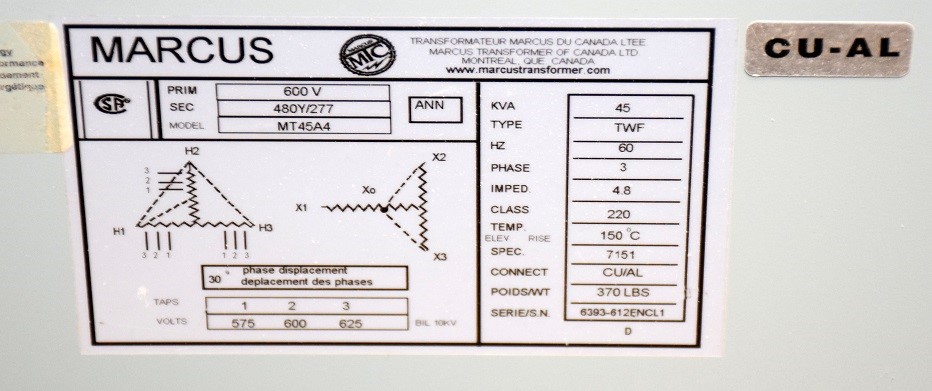

480 VOLT, 3 PHASE (COMES WITH TRANSFORMER TO 600 VOLT)

RIG & LOAD FEE.....$ 1500.00 OR USE YOUR OWN RIGGER.

US CUSTOMS BROKER..."NEAR NORTH" (716) 204-4020

US BUYERS SHIPPING QUOTES:

ALWAYS TRUCKING...AARON (541) 608-6532

SHIPPING WITHIN CANADA QUOTES;

MANITOULIN TRANSPORT (800) 268-9994

OVERSEAS CONTAINER QUOTES:

LISA JONES (416) 896-2688

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginUS CUSTOMS BROKER..."NEAR NORTH" (716) 204-4020

US BUYERS SHIPPING QUOTES:

ALWAYS TRUCKING...AARON (541) 608-6532

SHIPPING WITHIN CANADA QUOTES;

MANITOULIN TRANSPORT (800) 268-9994

OVERSEAS CONTAINER QUOTES:

LISA JONES (416) 896-2688

ALL SALES ARE FINAL

* CDN FUNDS: THIS AUCTION IS BEING HELD IN CDN FUNDS

* PAYMENT: IS REQUIRED WITHIN 48 HRS OF AUCTION ENDING. PLEASE DO NOT MAKE ANY FORM OF PAYMENT UNTIL RECEIVING YOUR INVOICE

* PAYABLE METHOD: TO EQUIPMENT AUTHORIYTY BY WAY OF WIRE TRANSFER, ETRANSFER OR DIRECT DEPOSIT ONLY.

* REMOVAL: AT BUYERS EXPENSE.

* REMOVAL DEADLINE: OCT 01 2019 (SMALL MACHINES) OCT 04 (LARGE) MACHINES

* INSPECTION: BY APPOINTMENT CALL ROBERT (416) 904-2475

* AUCTION END DATE: TUESDAY, SEPT 24 2019 AT 1:00 PM (EDT)

* BUYER PREMIUM: 15% BUYER PREMIUM SURCHARGE WILL BE ADDED TO THIS LOT

* AS IS WHERE IS: ALL MACHINERY & EQUIPMENT IS BEING SOLD AS IS WHERE IS WITH NO WARRANTY.