Anderson "Andimaxx 1631TC" CNC Router w/ Roller Hold Down  Ended

Ended

2016 Anderson Andimaxx CNC Router - Anaheim, CA

- Winning Bid : $85,250.00 USD Sold

- 51 Bid(s)

- High Bidder: a****5

Anderson "Andimaxx 1631TC" CNC Router w/ Roller Hold Down - Anaheim, CA ( Closed #15233994 )

Sale by order of secured creditor. Machine has been uninstalled and moved to rigger's storage facility for loading convenience.

-

Item Location

3839 E. Coronado St. Anaheim, CA 92807

-

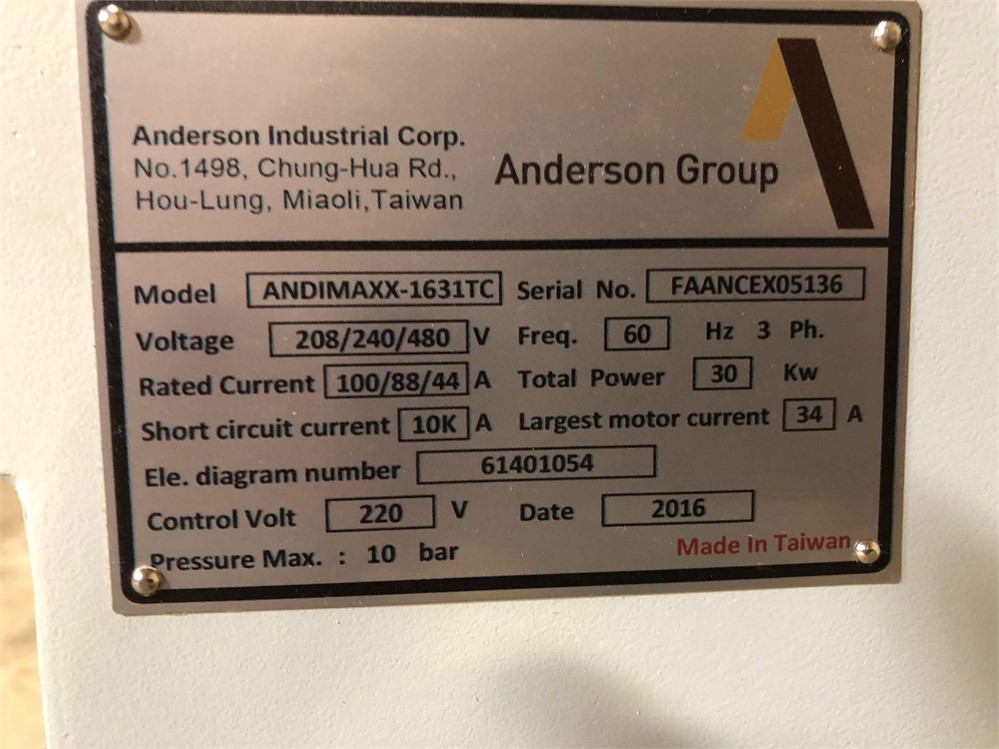

Make

Anderson

-

Model

Andimaxx 1631TC

-

Serial Number

FAANCEX05136

-

Year

2016

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Inspection Date

By appointment only, contact Jack Ragan

-

Final Removal Date

April 12 2019

-

Estimated Dimensions

See description for details

-

Estimated Weight

31,000 Pounds

-

Seller Comment

Non Negotiable Loading Fee $3,000

-

page views

5057

Anderson Andimaxx 1631TC CNC Router w/ Roller Hold Down

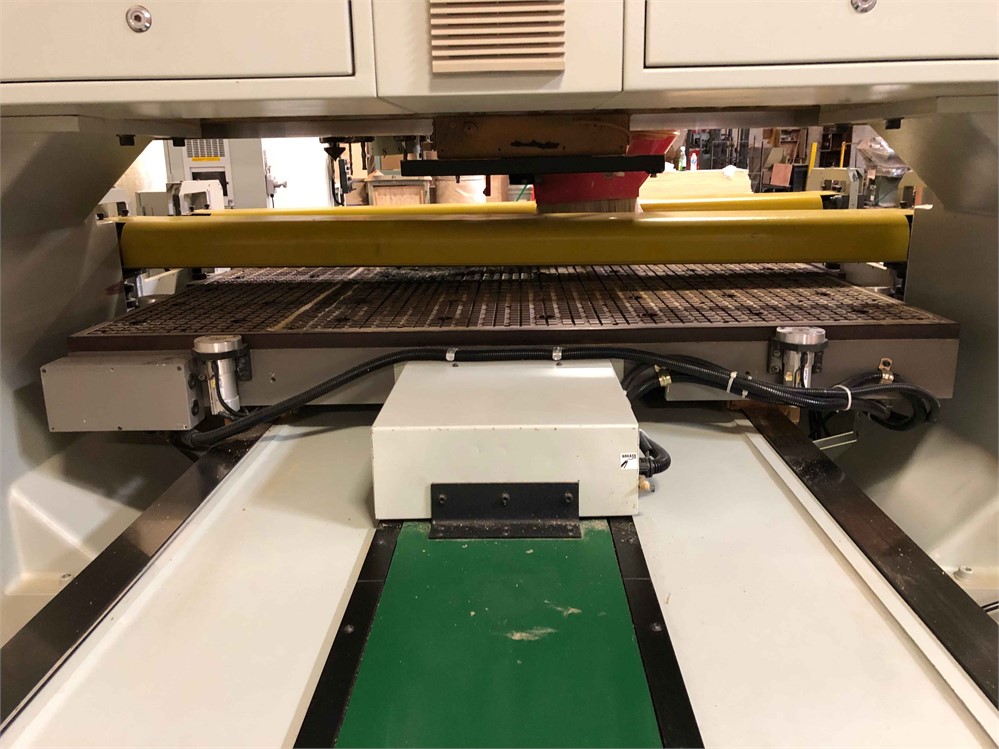

319" L x 142" W x 116" H machine footprint as show in photos

One (1) 24 HP router motor

HSK 63 F

1,000 - 22,000 RPM

Full torque acheived at 9,000 RPM and full HP acheived at 12,000 RPM

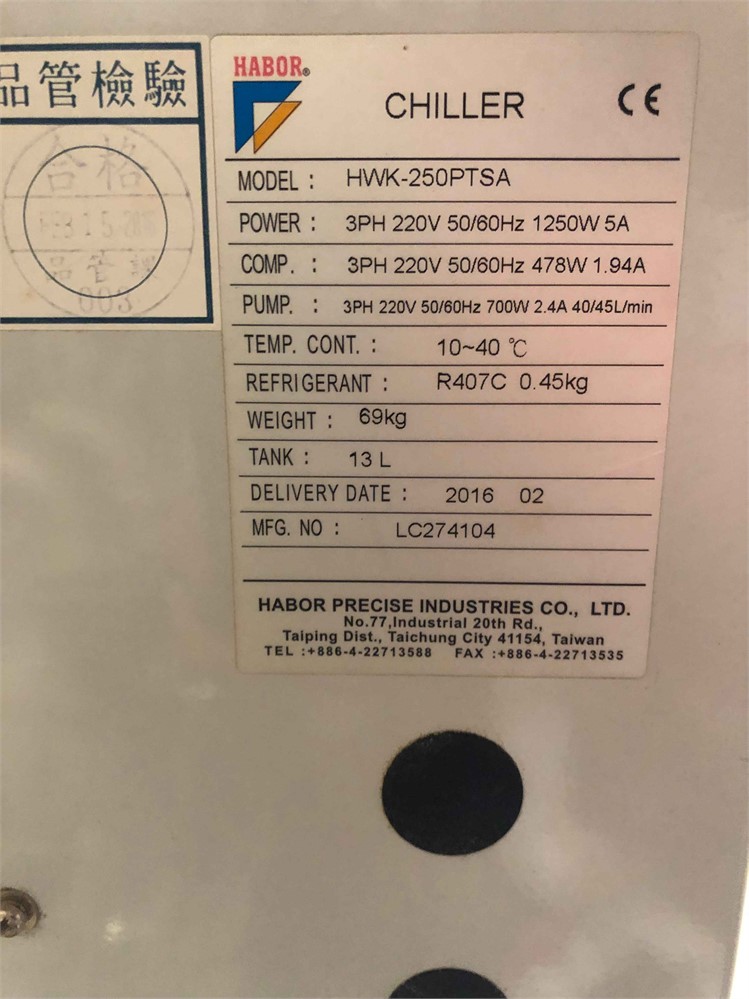

Chller unit for router motor

18" L x 14" W x 37" H

150 Pounds

Ten (10) postion rotary tool changer

Pheolic gridded table with one (1) vacuum zone

63" x 122"

Axis stroke: X axis 79", Y axis 137", Z axis 10"

Maximum rapid rate: X axis 80 m/min., Y axis 80 m/min., Z axis 30 m/min.

Maximum feed rate: X axis 80 m/min., Y axis 80 m/min., Z axis 30 m/min.

Eight (8) pneumatic reference pins

Roller hold-down system for high volume production of stacked sheet goods

Fanuc AC motor drives for x, y and z axes

Automatic lubrication

Control cabinet

60" L x 20" W x 69" H

1,000 Pounds

Fanuc OiMD controller system with Dell PC front-end

Tool length touch probe

Remote control pendant

Tool setup stand

24" L x 14" W x 36" H

200 Pounds

Tool holders and tooling and in photos included

Flexible hoses included

Dekker liquid ring vacuum pump

VMC0553KA1-00 (model)

26409 (serial number)

80" L x 30" W x 66" H

1,000 Pounds

OnDek control system

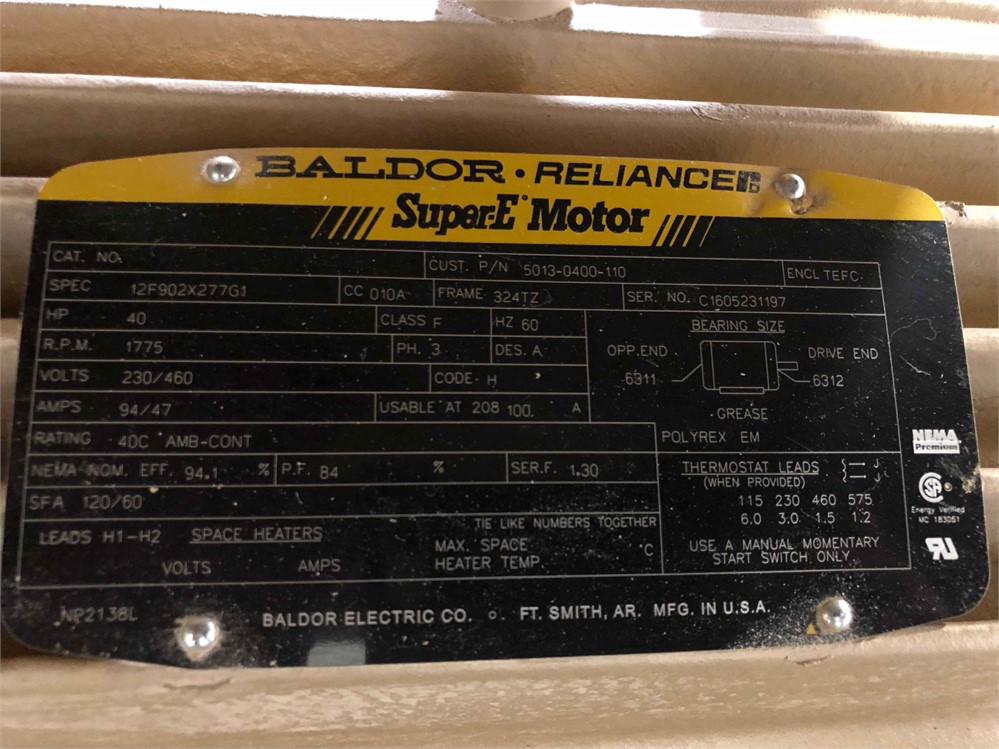

40 HP Baldor motor operating at 1,775 RPM

550 CFM

29" Hg

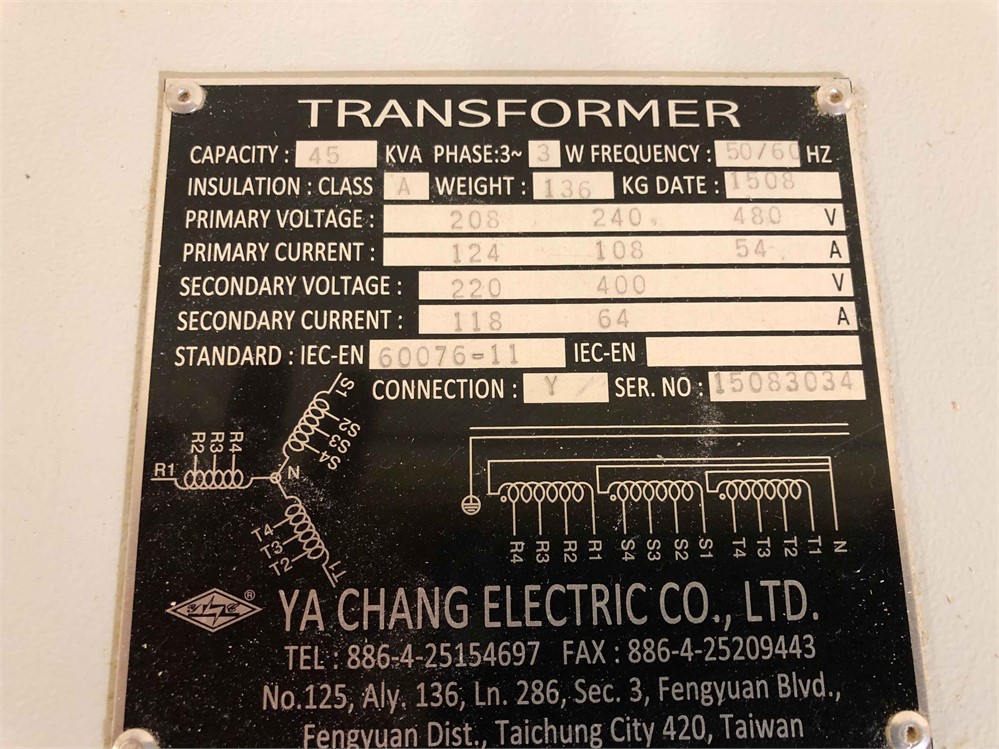

External transformer

21" L x 17" W x 22" H

300 Pounds

Fixed Bridge (moving table) type machine equipped with 1 (one) 24 HP 4-pole liquid-cooled router spindle, with grease lubricated ceramic bearings, a 10-Position Automatic Tool Changing System, with tool length touch probe. The spindle motor is powered by an electronic AC inverter drive system with dynamic spindle braking. Full Torque is achieved at 9,000 RPM & Full HP is achieved at 12,000 RPM. The Tool Changer Carousel is mounted on the spindle carriage, next to the Router Spindle, for fast & efficient tool changes.

X & Y axes are constructed of massive, heavy duty welded steel construction with multiple reinforcements to increase strength and absorb vibration. Z-axis spindle carriage is a specially designed Meehanite casting for high strength and inherent vibration dampening characteristics with a pneumatic counterbalance system for smooth & accurate operation.

Hardened & Precision GROUND Rectangular Boxway guide-ways, with recirculating roller bearings, are provided for all primary movements in the X & Y axes. Roller Boxways provide far more metal to metal contact than radius-contact ball guide systems for up to twice the load capacity, one third the elastic deformation, twice the static stiffness, up to 200% longer life, with significantly better dampening of tool induced vibrations. Hardened and precision STAR profiled linear guide way systems with recirculating roller linear bearings are provided for movements in the Z axes. Hardened precision ball screws with anti-backlash ball nuts are provided for all primary movements of the X, Y, & Z axis.

The vacuum table is made of torsion resistant cast steel, covered with a 30mm thick phenolic grid table top for the quick and easy mounting of work pieces via pods, clamps, spoil-boards, or holding fixtures. Eight (8) pneumatically controlled Pop-up pins are mounted around the table perimeter for Nested Based Manufacturing. Includes a specially designed Roller Hold Down system designed for high volume production of stacked sheet materials. The Roller-Hold-Down option is intended for furniture frames, marine plywood parts, high volume nested based manufacturing, Starboard, or stacks of thin plastic sheets.

The table is configured with one vacuum zone, which is m-code controlled. The vacuum zones are equipped with a low vacuum sensor. State-of-the-art closed loop FANUC AC digital servo motors

Automatic oil lubrication is utilized for box guide ways & ball screws. Centrally located grease fittings are utilized for end bearings and profiled linear guide ways. All guides are protected from dust and other contaminates by double sealed wipers. The operator control panel has a Handheld Pendantwith separate Feed Rate & Rapid Rate Override. A dust collection hood with automatic damper system is provided for the router spindle.

FANUC OiMD Controller System + PC Front End (IPC Win.7 by AIC)

With “FAST CORNER FUNCTION”, and the following standard features:

This Anderson CNC Proudly uses the latest, Series 0i-MODEL D, with nano-resolution performance. With over 700,000 systems installed, the 0/0i from FANUC is by far the world’s most popular CNC control. Operational & programming consistency are critical to maximize productivity. Operators that already have experience with FANUC controls will be comfortable with the Series 0i in no time, with little or no additional training. Existing part programs will typically run without modification. Each operator can select their preferred language quickly from any one of the 16 supported by the 0i.

High-capacity, nonvolatile internal memory is provided for part program storage. Slots are provided for an additional 2GB of part program storage using economic ATA or Compact Flash memory cards. Part programs stored in external memory cards can be edited & executed just like internal memory, providing practically unlimited capacity.

The network-ready 100-MBit Ethernet interface allows the CNC to be integrated into a network for high-speed part program transfers & the collection of process related data. It also supports remote troubleshooting from the maintenance departmentanywhere around the world. The Ethernet port doesn’t use a public operating system,so it’s practically “hacker-free” & virus immune.

The Series 0i-MODEL D achieves the highest precision possible, with nanometer resolution standard throughout the CNC system. Fast, high resolution 16-million count-per-revolution feedback devices combine to provide a superior surface finish quality when contouring. This minimizes the need for secondary operations, reducing delivery times & part cost.

The Series 0i features a suite of advanced motion control software functions to reduce

cycle times while enhancing part accuracy & extending machine life. Bell shaped

acc/dec minimizes machine shock & reduces the time it takes to accelerate &

decelerate during rapid, contouring, & tapping motions. A.I. Contour Control looks

ahead in the part program to eliminate the acc/dec & servo delays that limit feed rates

when cutting short line segments or contours, & effectively eliminates machining

trajectory error in corners & small radii. Nano smoothing converts CAM-generated line

segments into NURBS curves for faster execution & a superior surface finish, without the need for drastic modifications to existing part programs. High-efficiency drive systems pump energy back into the power line when the machine is decelerating, and when combined with cycle time reductions, they reduce electrical power consumption by up to 50%. Plus, the CNC system is ‘ready-to-go’ in less than 30 seconds.

FANUC’s culture of quality ensures that our CNC systems are the most reliable available. Statistically, aFANUC hardware fault occurs only once for every 27 years of productive service (MTBF). With the commitment of a 25-year parts availability guarantee, convenient local parts inventories, over 34 US locations, & economical repair and return services, you can look forward to decades of trouble-free operation with the Confidence that your machine will be available for production when you need it.

The FANUC 0iMD Controller System is open architecture and will accept industry standard G-Code from any CAD/CAM or Screen-To-Machine program available.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed. Machine has uninstalled and moved to rigger's storage facility for loading convenience. Please contact Shanan Cogbill at Walker Brothers Machinery Moving @ 714-495-4603 or [email protected].

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.