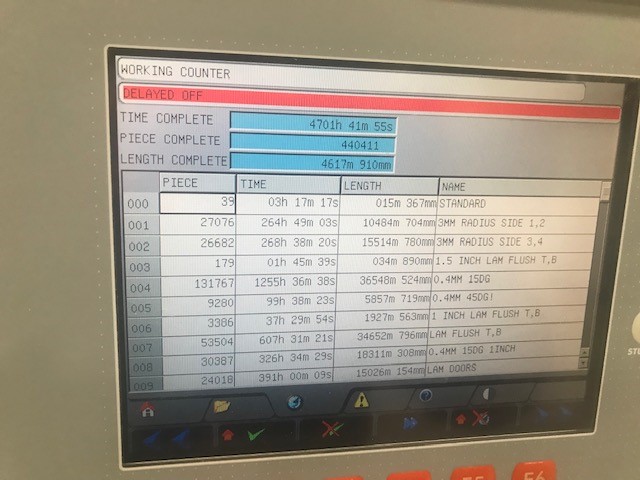

HOLZHER "SPRINT 1321" HEAVY DUTY AUTOMATIC EDGEBANDER, YEAR 2006  Ended

Ended

LATE MODEL HOLZHER EDGEBANDER AUCTION, DAYTON OHIO

- Winning Bid : $6,201.00 USD Sold

- 41 Bid(s)

- High Bidder: u****o

HOLZHER SPRINT 1321 AUTOMATIC EDGEBANDER AUCTION, DAYTON OHIO ( Closed #14297378 )

YEAR 2006 HEAVY DUTY HOLZHER MODEL SPRINT 1321 AUTOMATIC EDGEBANDER UP FOR BID TO THE HIGHEST BIDDER. AUCTION LOCATION: 140 NORTH KEOWEE STREET DAYTON OHIO 45402 AUCTION CLOSES JANUARY 16TH, 2019 STARTING AT 10:30 AM PACIFIC TIME. **IF YOU WOULD LIKE TO VIEW MACHINE PRIOR TO AUCTION CLOSE, PLEASE CONTACT KIRK @ 925-250-8248.

-

Item Location

DAYTON OHIO 45402

-

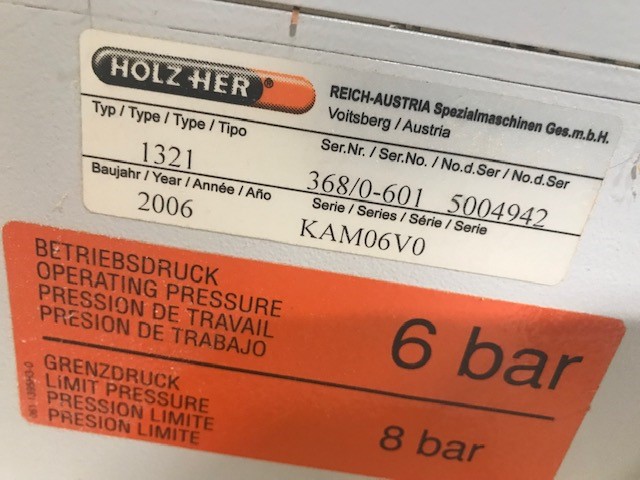

Make

HOLZHER

-

Model

SPRINT 1321

-

Serial Number

368/0-601 5004942

-

Year

2006

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Inspection Date

CALL KIRK @ 925-250-8248

-

Final Removal Date

JANUARY 21ST, 2019

-

Estimated Dimensions

EMAIL OR CALL

-

Estimated Weight

-

Seller Comment

-

page views

1729

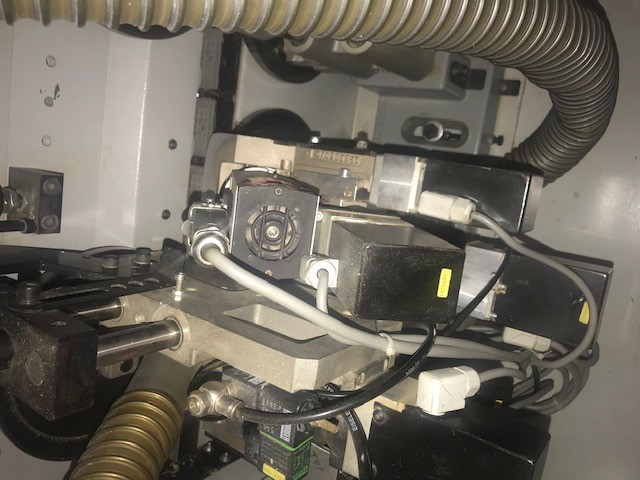

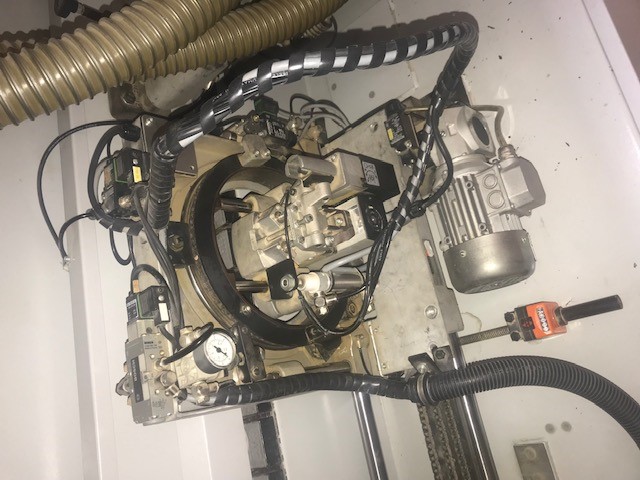

HOLZHER MODEL #SPRINT 1321 HEAVY DUTY AUTOMATIC EDGEBANDER MACHINE

YEAR 2006 BUILT MACHINE

3-PHASE

SERIAL #368/0-601 5004942

**SPECS. AS PULLED FROM MANUFACTURER WEBSITE: PLEASE DO OWN DUE DILIGENCE ON EXACT SPECS. OF THIS PARTICULAR MACHINE.

Description

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginWINNING BIDDER IS RESPONSIBLE FOR REMOVAL OF ITEM.

PAYMENT IS DUE WITHIN 24 HOURS OF AUCTION CLOSE TIME. WIRE TRANSFER PAYMENT IS THE PREFERRED METHOD OF PAYMENT.